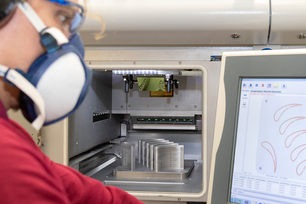

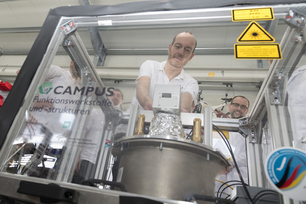

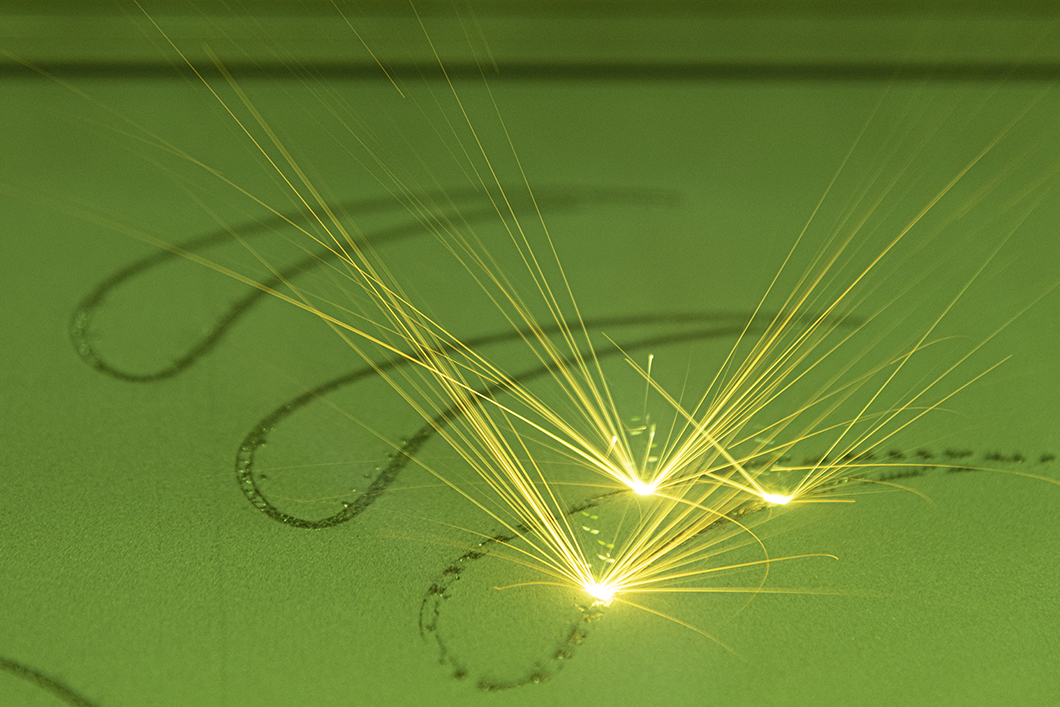

BAM is researching new processes for additive manufacturing, such as laser beam melting for metallic components.

Source: BAM

Using 3D printing for safety-relevant applications

More and more companies are investing in additive manufacturing in order to produce high-quality and complex components faster and more efficiently. However, reliable criteria and procedures for the testing and quality assurance of additively manufactured components are still lacking. This makes their use in safety-relevant applications, such as the production of aircraft parts or in medical technology, currently still very complex.

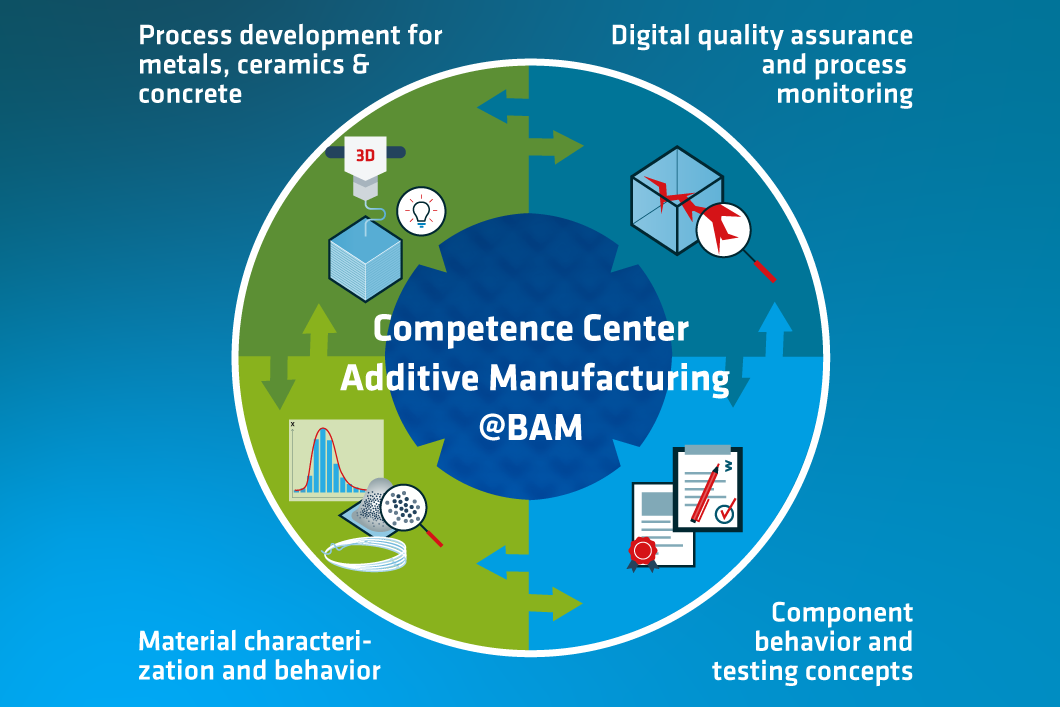

This is where BAM's Additive Manufacturing Competence Center comes in: It pools our interdisciplinary expertise in additive manufacturing technology, materials analysis and non-destructive material testing in order to make the use of additively manufactured components in safety-relevant applications suitable for industrial use.

Comprehensive expertise and excellent research infrastructure

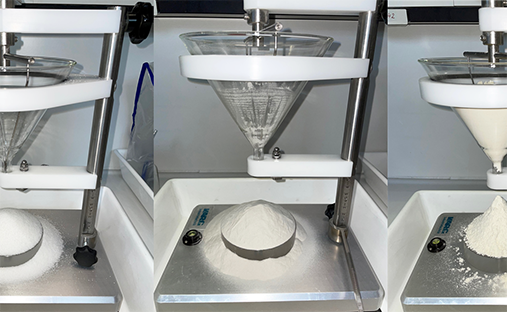

BAM has state-of-the-art facilities for additive manufacturing processes for metals and develops its own processes for ceramic and cement-based materials. From the starting materials to the end product, the material properties of additively manufactured components can be comprehensively determined and tested, including under mechanical, thermal and corrosive stresses.

AM@BAM: Services and competences

Our services include:

- Additive manufacturing of metallic, ceramic and cement-based materials

- State-of-the-art infrastructure for metals: laser beam melting (L-PBF), laser powder cladding (LMD), arc generation (WAAM), binder jetting

- Optimization of additive manufacturing processes and process development

- Evaluation of process influences such as heat treatments and machining post-processing

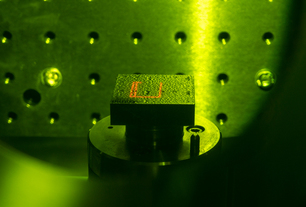

- Non-destructive material characterization

- Corrosion testing

- Comparative and interlaboratory tests

- Living lab "Additive Manufacturing": digital quality infrastructure for modern manufacturing

Our fields of competence

- Characterization of material properties

- Component behavior and test concepts

- Process development

- Process monitoring

BAM's fields of competence in additive manufacturing

Source: BAM

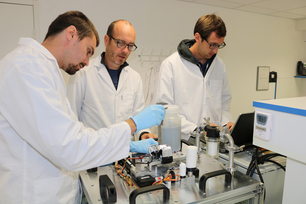

BAM is closely networked with industry in order to quickly transfer the scientific findings into applications. For example, the competence center works together with the Werner-von-Siemens Centre for Industry and Science in Berlin.

Selected projects

Junior research gourp TransNanoAF

DOI4AM - Digital Object Identifier for additively manufactured parts

QI-Digital - New solutions for a modern, agile quality infrastructure (QI)

Find BAM research projects in the field of materials and other topics in the ReSEARCH BAM database

Selected publications

Additive Fertigung an der BAM: Sicherheit im Fokus / Broschüre, 03/2019 (PDF, 4MB)

Microplastic response of 2PP-printed ceramics

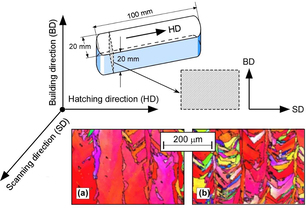

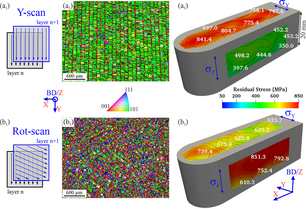

Impact of scan strategy on principal stresses in laser powder bed fusion

Further publications can be found in our database PUBLICA.