Sabine Kruschwitz at the NMR-Tomograph

Source: BAM

Project period

01/11/2020 - 30/09/2022

Project type

BAM project

Project status

Ongoing

Description

The hydration behaviour of newly developed building materials is non-destructively studied by 1H NMR. By comparisons with reference methods such as the Vicat or heat flow calorimetry test, different hydration stages are classified.

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

Apartment block in Berlin, built by Le Corbusier 1957 Source: BAM

The global demand for cement-based building materials is high and still rising as they have become an indispensable part in modern building culture. However, the production of Portland cement mixes comes along with very high greenhouse gas emissions which significantly contribute to the current climate crisis. This shall be overcome by adding so called supplementary cementitious materials and significantly reducing the actual amount of Portland cement in the mixes.

Source: BAM

With the development of new and more environment-friendly mixes, studies which focus on their performance and hydration behaviour are needed. Within the scope of this project, the applicability of 1H NMR as a new tool for material characterization shall be tested. Thereby, the focus especially lays on the suitability to observe main hydration events and the solidification of the fresh cement pastes. Also, pore space and durability features will be determined in-situ on the hardened samples.

Source: BAM

To study the hydration and hardening process, 1H NMR measurements are conducted in an automated way for several hours or even days. Main focus of our project are geopolymers or other alternative binders, where the cement is partially substituted by organic (waste) products such as cassava peel ash or cocoa. We study the effect of superplasticizers. Pure white cement samples serve as a reference. We compare our observations with NMR to characteristic changes in the material like e. g. the needle penetration depth or the heat flow development.

Source: BAM

Partners

Bundesanstalt für Materialforschung und -prüfung (BAM)

Department Non-Destructive Testing

with the support of

Department Safety of Structures

Technology of Construction Materials division

Funding

The HyBeMa project is funded from BAM internal funds.

HyBeMa - Study on the hydration behaviour of new building materials with NMR

Cement-based building materials have become an indispensable part in modern building culture, and the global demand is still rising. However, high CO2 emissions from the cement production are a challenge. Facing the global climate crisis, new and more environment-friendly building materials are a way to decrease the large CO2 footprint of cement production. Such “green” building materials may be achieved by significantly reducing the amount of cement in the binder and recycling, by e. g. reusing used concrete fragments as aggregates. However, such newly developed materials need detailed investigation before their application. The focus thereby should lay on the hydration processes and their material performance, especially as durability is concerned.

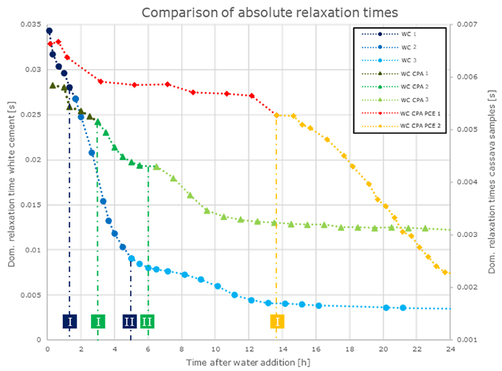

Within the scope of this project, classic white cement mixtures and several newly developed cement-reduced mixtures are studied during hydration with the non-destructive testing tool 1H NMR . NMR is sensitive to the amount and mobility of hydrogen protons within the sample and therefore shows significant changes in the temporal development of the measured relaxation-time distributions during hydration. The NMR measurements can be automatically conducted with adaptable measurement rates by use of an NMR tomograph. Typically, the hydration behaviour is monitored for 24 h or up to 100 h.

Besides classic white cement as reference material, the newly developed mixtures include for example mixtures, where the cement is partially replaced by organic (waste) products such as cassava peel ash or cocoa. Moreover, complete cement-free alternatives such as geopolymers are investigated.

Temporal development of NMR relaxation times of a pure white cement sample (WC), a white cement sample that is partially substituted with cassava peel ash (WC CPA) and a white cement sample with CPA substitution and added superplasticizer (WC CPA PCE); I and II demonstrate the time of the main C-S-H hydration event and the setting.

Source: BAM

The aim of this project is to achieve new insights into the studied materials and to evaluate the applicability of NMR as a new standard tool for material characterization. It shall enable the classification of important hydration events such as the C-S-H forming and the moment of solidification. As yet, the Vicat-test and heat flow calorimetry are used as reference methods and are helpful tools for the interpretation of the NMR results.

This project supports the SealWasteSafe project (webpage in German).

Partners

Bundesanstalt für Materialforschung und -prüfung (BAM)

Department Non-Destructive Testing

with the support of

Department Safety of Structures

Technology of Construction Materials division

Funding

The HyBeMa project is funded through internal BAM funds.