Application of a KorroPad on a stainless steel ring

Source: BAM

Whether it is a car, a skyscraper or a bridge: stainless steel is used almost everywhere in our daily life. Due to its metallic, corrosion-free surface it is particularly suitable for components or decorative elements. Its corrosion resistance is important so that no safety risk arises. Stainless steels can be tested non-destructively in just 15 minutes using the rapid colour test developed by BAM before they are ever used.

Tiny weak spots in the steel

Stainless steels are covered by a layer of chromium oxide a few atoms thin, also called a passive layer, that protects the metal from further corrosion. If there are weak spots in the protective layer due to manufacture or processing, undesired corrosive reactions can occur. As a result, optical appearance may be impaired and damage causing safety risk can arise.

Early and fast damage detection

A research team from BAM’s Corrosion and Corrosion Protection Division has developed a test that reveals faulty surfaces ofin stainless steels. The KorroPad method can visualise damage to the passive layer quickly and non-destructively using a colour indicator for iron ions. The passage of iron ions changes KorroPad’s colour to "Prussian blue" so revealing an incomplete passive layer.

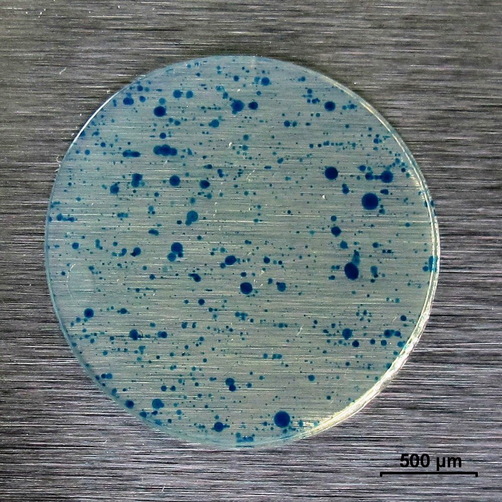

Three pads, each about the size of a five-cent coin, are required for each test. The pads are pressed onto the cleaned surface and peeled off with a spatula after 15 minutes. If the passive layer is faulty, the indicator reacts with the iron ions in the material during the test and blue dots appear on the slightly yellowish pads. Each point indicates spots where the protective passive layer has not formed properly on the steel surface.

Blue dots on KorroPad indicate corrosion susceptibility of steel.

Source: BAM, Corrosion and Corrosion Protection

Easy and uncomplicated test even for a nonprofessional

In addition to being quick to carry out, KorroPad has further advantages: even laypersonsnonprofessionals can apply it due to an easy application and simple evaluation, and the test leaves no residues or traces on the surface. The KorroPad method developed by BAM helps prevent safety problems due to defective material before further processing.