High temperature mechanical testing of additively manufactured specimens

Source: BAM

The effects of fatigue damage on the load-bearing capacity and integrity of AM metallic structural components limits their suitability for fatigue-related applications. Despite intensive research work, this problem cannot yet be regarded as solved. The most important factors, which influence the overall service life and fatigue strength as well as the fatigue crack growth, including the threshold value, are the surface integrity including roughness, cavities such as pores and, much less favourable, non-fused regions of material. Furthermore, the inhomogeneity and anisotropy of the material as well as the way in which material texture affects the cracking propagation path, such as through build-up direction and hatching strategy, play an important role. Finally, the residual stresses also are expected to influence fatigue behaviour, whereby the redistribution and, in the best case, relaxation of these stresses under vibration loading needs to be considered.

One of the activities in the BAM project AGIL (Microstructure Development in Additively Manufactured Metallic Components) is the investigation of fatigue behaviour by means of fracture-mechanical methods, whereby theoretical modelling and experiments are combined. In this approach, both long and short crack growth are considered, which, along with classical crack propagation and residual service life analysis, should also enable the determination of the total service life and the fatigue strength.

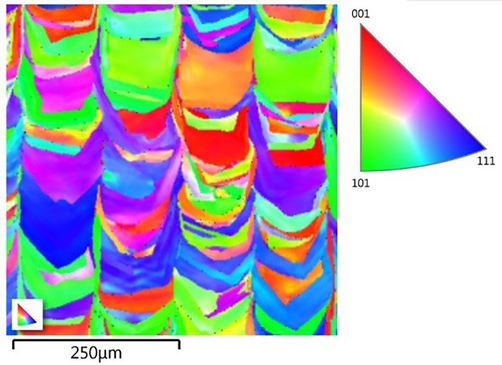

REM/EBSD-Aufnahme der Kristallstruktur von additiv gefertigtem Edelstahl in Baurichtung

Source: BAM

A further aspect of the modelling is the microstructure- based simulation of the mechanical behaviour of AM materials. Real grain structures from microstructure analysis are transformed into virtual grain structures by 3D reconstruction from EBSD (Electron Backscattering Diffraction) data and deformations and stresses are calculated using crystal plasticity models. EBSD is used to determine and map phases and their orientation, i.e. the crystal structure of the material.

The built-up structure with its layered beds of melted material is overlaid by the crystal structure. The geometric characteristics of these structures do not identically match. In addition to determing the fatigue strength, the fracture behaviour is also investigated via fractography. Fractography can be used to follow the crack propagation through additively manufactured microstructures of metals.