Offshore wind turbines are advancing into new dimensions. The Competence Centre Win@BAM is conducting research into their safe operation.

Source: iStock/fokkebok

Wind energy: Safe systems that defy wind and weather

A rapid expansion of wind energy is crucial if Germany is to become climate-neutral by 2045. This poses technical challenges: Modern offshore turbines set new standards with their height of up to 260 meters, the rotor blades alone have a larger wingspan than a wide-body jet. This places special demands on the material, which has to withstand storms, waves, currents and salt water.

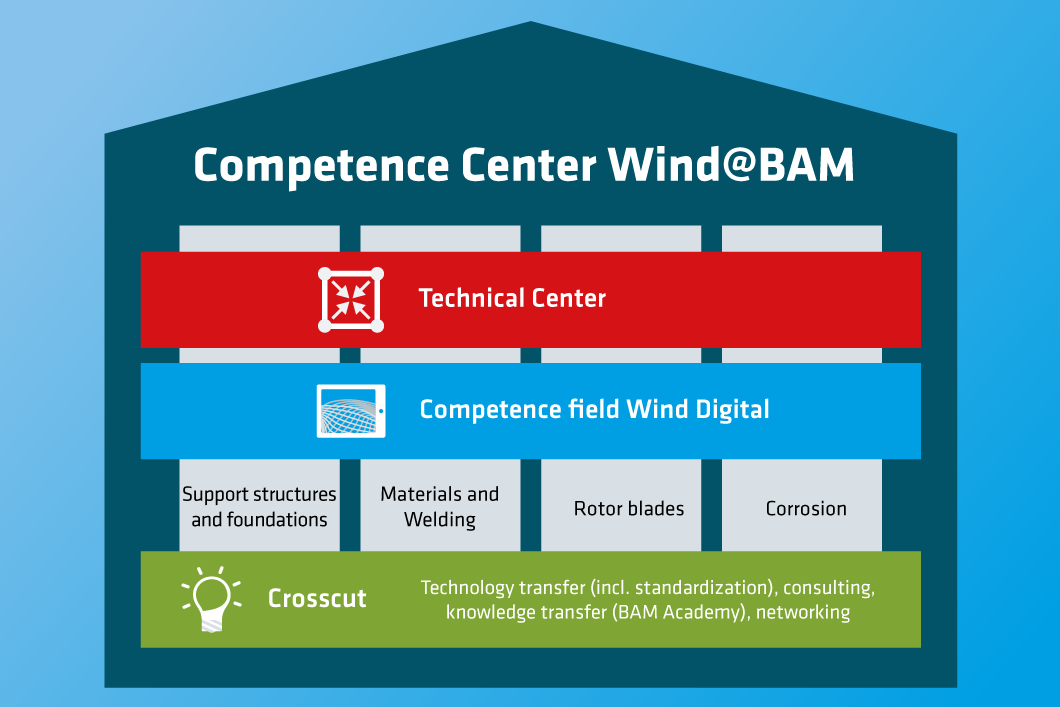

BAM has been conducting extensive research into the safety of wind turbines for two decades and has pooled its expertise in this field in the Wind@BAM Competence Center. In this way, we are supporting the German government's energy transition.

Research into innovative lightweight materials, welding techniques and turbine monitoring

The focus of the Competence Center is on mechanically stressed components such as rotor blades, support structures and foundations. With our unique infrastructure, we can test large components for strength, fatigue and durability. We also investigate the challenges faced by offshore installations due to corrosion and develop suitable protection methods.

BAM is also researching the use of innovative lightweight materials and high-strength steels in wind turbines and optimizing the corresponding welding techniques. In this way, we are leveraging the potential to save large quantities of material and CO2.

Research into turbine monitoring using sensor-based measurement technology and innovative non-destructive testing applications such as passive thermography complete the portfolio. They make BAM a strong partner for industry and science in the field of wind energy.

Wind@BAM: Services and competences

- Mechanical tests by means of special large-scale testing facilities

- Fatigue testing for large components

- Simulation of installation processes

- Lightweight construction with high-strength steels to optimise component stresses

- Development of automated manufacturing concepts of foundation structures - digitalisation of the manufacturing and inspection chain

- Increasing economic efficiency and safety through reproducible production concepts

- Concepts for generative manufacturing of high-strength components

- Damage analysis

- Development of repair concepts

- Structural health monitoring

- Inspection planning and digital data modelling

- Lifetime extension concepts

- Atmospheric corrosion in marine environments

- Corrosion and corrosion protection of offshore foundation elements

- Electrochemical investigations in the real seawater laboratory

BAM's fields of competence in wind energy

Source: BAM

Selected projects

CEEC (Center of Excellence for Exascale CFD)

ReNEW - Tools for supporting decisions on lifetime extension and repowering of wind turbines

DiMoWIND-Inspect - Effectively inspecting offshore wind turbines

BeKoRi - Evaluation of solidification cracking during welding of high-strength fine-grained structural steels

PhoSten - Prevention of cold cracking in thick plate welds of high-strength steels

SmartWeld - Lightweight construction through innovative design and manufacturing concepts

insituLIPS - Challenges in welding duplex stainless steels

HAZ softening - Softening mechanism during welding in the heat-affected zone of microalloyed high-strength steels

EvalTherm - Passive thermography for rotor blade damage on wind turbines

GW4SHM - Guided Waves for Structural Health Monitoring

VERBATIM - Dents in thick sheet metal (in German)

PROVING - Production, optical and virtual verification and manufacturing

Optimisation of welding-related stresses and crack prevention

Generative manufacturing of high-strength components

Find more BAM research projects in the field of energy and other topics in the

ReSEARCH BAM database