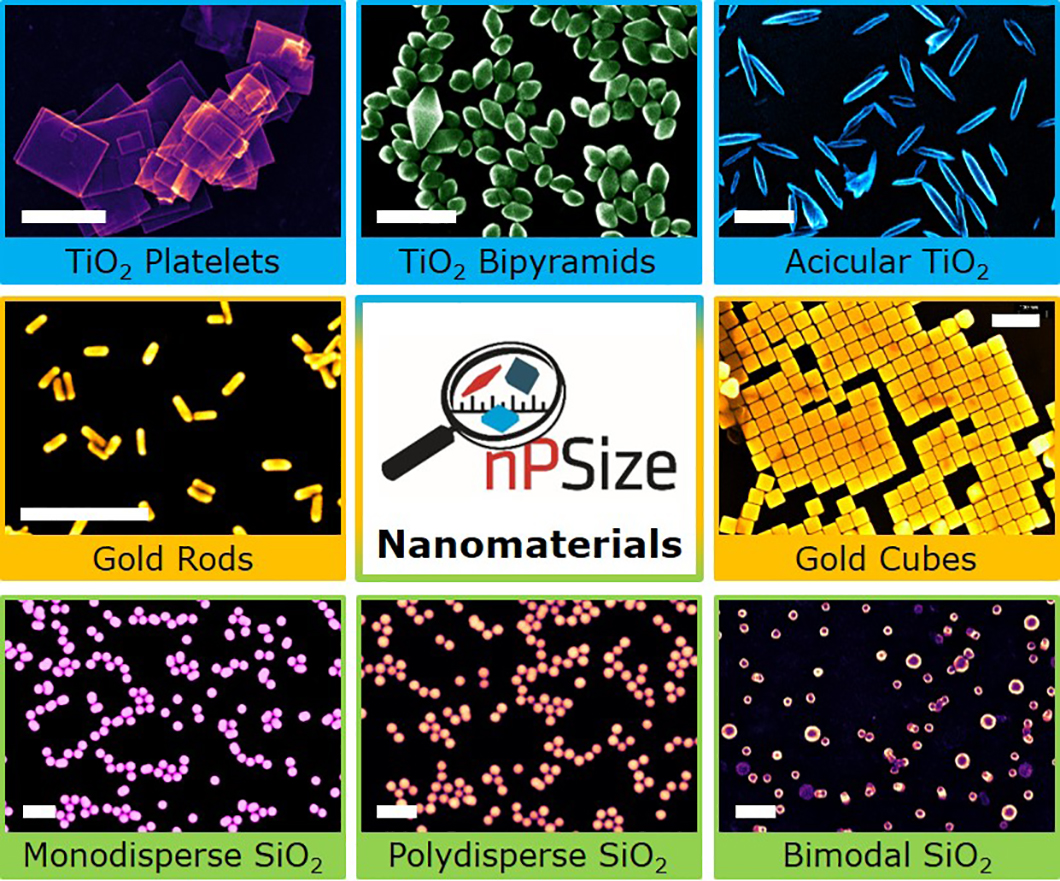

The nPSize materials: Towards certified, non-spherical, non-monodisperse reference nanoparticles. Scale bars equal 100 nm.

Source: BAM, Surface Analysis and Interfacial Chemistry Division

Project period

01/05/2018 - 31/10/2021

Project type

EU project

Project status

Closed

Description

This project will develop methods, reference materials and modelling to improve the traceability chain, comparability and compatibility of nanoparticle size measurements.

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Branch Fabeckstraße

Unter den Eichen 44-46

12203 Berlin

Source: BAM

Source: BAM

Source: BAM

Contributions to improve the capability of traceable measurement of nanoparticle size and shape, lower uncertainties of nanoparticle size measurement by new reference materials, physical modelling and machine learning, 3D method combination, new ISO and CEN standard on accurate nanoparticle size measurement, guidance and knowledge transfer.

Source: BAM

Consortium: 5 Metrological Institutes (LGC, LNE, PTB, SMD and VSL), 1 Designated Institute (BAM) and 4 external funded partners (CEA, DIN, POLLEN and University of Turin) from 6 European countries

Coordination: Dr. Vasile-Dan Hodoroaba, Bundesanstalt für Materialforschung und -prüfung (BAM)

Funding: The project receives funding from the European Metrology Programme for Innovation and Research (EMPIR).

Overview

Nanomaterials and nanotechnology are widely used today, but their use may expose humans and the environment to new health and sustainability risks. To control and minimise these risks, the European Commission has mandated European standardisation bodies to develop standardised methods that can reliably characterise manufactured nanomaterials. This project will develop methods, reference materials and modelling to improve the traceability chain, comparability and compatibility of nanoparticle size measurements to support standardisation within the framework of CEN/TC 352 “Nanotechnologies”, ISO/TC 229 ‘Nanotechnologies’, ISO/TC 24/SC 4 ‘Particle characterization’ and ISO/TC 201/SC 9 ‘Scanning probe microscopy’.

Need

The global nanotechnology market is predicted to reach 110 Billion US$ by 2022. Further, nanotechnology has been identified by the European Commission (EC) as one of its 5 key technologies. New and emerging uses of nanomaterials include medical and pharmaceutical applications as well as use in conductive inks, optical sensing and power delivery. However, nanotechnologies and nanoparticles may expose humans and the environment to new health and sustainability risks, which need to be reliably linked to their size, shape and chemical properties.

In order to support the increasing and safe use of nanomaterials it is essential that robust normative standards are introduced. NMIs have a key role to play in this by developing comparable and traceable measurements and instrument calibrations for real-world nanoparticles. The EC has recognised this need and therefore mandated CEN, CENELEC and ETSI (EC Mandate M/461) to develop standardisation activities regarding nanotechnologies and nanomaterials as one of the building blocks for the “safe, integrated and responsible” use of nanomaterials as outlined in the EC European Strategy for Nanotechnologies. A significant part of this strategy relates to the need for improved, traceable measurement procedures for size of real-world nanoparticles as a prerequisite for the reliable evaluation of their potential toxicity to the environment.

Three different ISO technical committees offer suitable standardisation platforms for projects on the accurate measurement of nanoparticle size and shape distribution: ISO/TC 229 for electron microscopy, ISO/TC 201/SC 9 for atomic force microscopy (AFM) and ISO/TC 24/SC 4/WG 10 for small angle X-ray scattering (SAXS). Whilst three projects on the measurement of nanoparticle size and shape distribution using scanning electron microscopy (SEM), scanning electron microscopy in transmission mode (TSEM) and transmission electron microscopy (TEM) are in development under ISO/TC 229, there is no similar standardisation project at the European level under CEN/TC 352 yet. Alignment of European standardisation activities within CEN/TC 352 to the ongoing ISO standardisation projects is necessary. The physical modelling of the output signals in electron microscopy and new reference nanoparticles with more complex shape and size distribution are also required. This is also the case both for future AFM standards on the measurement of nanoparticle size and shape distribution, which would be developed under ISO/TC 201/SC 9, and for the SAXS activities on nanoparticle size distribution in progress under ISO/TC 24/SC 4/WG 10.

The preselection by the present project of only traceable sizing methods is of special relevance. For the first time, both critical aspects, namely the lack of reference nanoparticles and signal modelling are systematically considered. The advanced data analysis software developed by the present project together with a public database with representative documented data will include a robust determination of the measurement uncertainty.

Objectives

The overall goal of this project is to improve the traceability chain, comparability and compatibility for nanoparticle size measurements to support standardisation and to ensure that these developments are fed into the standards development process within CEN/TC 352 and ISO/TC 229 and related groups. The specific objectives are:

- To assess the performance and establish the traceability of existing nanoparticle size and characterisation methods, such as SEM, TSEM, TEM, AFM and SAXS, in terms of their sensitivity to material, shape and quantity (number, volume or mass) for representative nanoparticulate materials (i.e. metals, oxides and polymers), including analysis of the effect of material and shape parameters on size and size distribution measurements, as well as the effect of conversion of the measured signal on the particle size distribution.

- To develop validated nanoparticle reference materials with (i) non-spherical shapes, (ii) non monodisperse size distributions and (iii) accurate concentrations. In addition, to use such nanoparticle reference materials to evaluate measurement uncertainties for nanoparticle quantity determination (expressed as number, volume, mass or intensity) and to establish their dependence on particle size.

- To develop improved physical models of the output signals from nanoparticle size measurement systems, that accurately account for nanoparticle material, shape and quantity. The physical models will include nanoparticle material type, shape and quantity parameters such as number, volume, and mass. The goal of the models is to improve the evaluation of nanoparticle measurement uncertainty and comparability between results of different methods.

- To use the new physical models to develop validated and traceable methods for the transfer of nanoparticle size from (certified) reference nanoparticles of spherical shape and monodisperse size distribution to other types of nanoparticles. This will include different nanoparticle shapes (such as elongated nanoparticles and platelets) as well as nanoparticles with non-monodisperse size distribution.

- To contribute significantly to the standards development work of the technical committees CEN/TC 352 Nanotechnologies and ISO/TC 229 Nanotechnologies ensuring that the outputs of the project are aligned with their needs, communicated quickly to those developing the standards and to those who will use them, and in a form, that can be incorporated into the standards at the earliest opportunity.

Progress beyond the state of the art

Performance and traceability of characterisation methods

Most previous studies on nanoparticle size measurement focus on suspensions of spherical and monodisperse nanoparticles and are limited to ‘simple’ systems such as gold, silica or polystyrene particles. Little or no research has been carried out on nanoparticles deviating from this idealised case. To address this, this project is currently investigating the sensitivity of traceable nanoparticle sizing techniques SEM, TEM, TSEM, AFM and SAXS to the type of nanoparticle material, shape, polydispersity and number concentration.

Nanoparticle Reference Materials preparation and characterisation

Currently, there are still no non-spherical nanoparticle reference materials or materials certified for particle concentration available on the market. Therefore, three classes of nanoparticle-reference materials (RMs) as a unique set are under development and will be validated in the project: particles with i) well-defined non-spherical shape, ii) relatively high polydispersity index, and iii) well-defined concentrations.

Modelling and development of measurement procedures

The project aims to improve the performance and traceability of current characterisation methods with advanced data processing. Different approaches are being considered including physical modelling of nanoparticle shape and simulations to evaluate the signals produced by input models for TSEM, SEM, AFM and SAXS. Modern modelling based on machine learning will be used with a-priori information from measured data. For the first time, the project is implementing physical modelling and will validate it into the machine learning algorithm.

Standardisation as knowledge transfer to end users

Project partners are actively contributing to the development of International and European Standards and Guidelines in collaboration with ISO/TC 229 ‘Nanotechnologies’, CEN/TC 352 ‘Nanotechnologies’, ISO/TC 24/SC 4 ‘Particle characterization’, ISO/TC 201 ‘Surface analysis’/SC 9 ‘Scanning probe microscopy’ and OECD Working Party on Manufactured Nanomaterials (WPMN) based on the new technical knowledge gained within this project. This cooperation with different technical committees focuses on the improvement of the traceability of the nanoparticle size measurements and quantity error evaluation, including method combination. All these aspects are currently addressed only partly or not at all within the respective standardisation projects and are completely absent from European standardisation. In addition, the project will facilitate uptake of the improved procedures, the unique RM candidates and models developed within this project by accredited laboratories, instrument manufacturers and reference material providers.

Results

1. Towards assessment of performance and establishment of the traceability of existing nanoparticle sizing methods, such as SEM, TSEM, TEM, AFM and SAXS:

The performance of the characterisation methods SEM, TEM, TSEM, AFM and SAXS for traceable measurement of nanoparticle size, size distribution, shape and concentration in suspensions are evaluated regarding parameters including calibration, measurement uncertainties and limitations. From these results, the key steps for measuring processes, i.e. sample preparation, data acquisition, metrological qualification and data analysis are being elucidated for each method. It was found that sample preparation using well-separated nanoparticle deposition on solid supports for EM and AFM methods is crucial for optimising performance regarding particle size distribution and shape analysis. As such, these methods are ideal candidates to accurately characterise particle shapes and sizes even within broad size distribution. However, EM and AFM methods have limited performance for analysing particle concentration, size ratios and agglomeration states in dispersion in comparison to SAXS. SAXS has good performance in analysing particle sizes and agglomeration state in dispersion but is not in favour to get accurate particle shape information for broad size distribution. Hence, EM/AFM and SAXS represent a perfectly complementary set of techniques in order to accurately determine all relevant parameters regarding nanoparticle size (distribution) and shape.

2. Towards development of validated nanoparticle reference materials with non-spherical shapes, non-monodisperse size distributions and accurate concentrations:

To identify the future needs for novel refence nanomaterial a public workshop with stakeholders from academia, industry and standardization committees was held at the beginning of the project. Based on the information gathered from stakeholders, eleven RM candidates were chosen and synthesized ranging from nanoparticles of titania, silica and gold that possess (i) non-spherical shapes, e.g. cubic, bipyramidal, acicular, flaky and/or (ii) defined concentration or (iii) polydisperse or bimodal size distributions. The following candidates were successfully synthesised: (i) titania nanoplatelets, (ii) titania bipyramids, (iii) titania acicular particles, (iv) gold nanocubes, (v) gold nanorods, and (vi) spherical silica particles with various size polydispersities. Spherical gold nanoparticles with accurate concentration were sourced and mixed accurately to nominal NP number concentrations. All synthesised nanoparticle candidates are undergoing characterisation with respect to their homogeneity and stability, using the methods from objective 1. Protocols for the deposition of the nanoparticles on silicon wafers, TEM grids and mica have been developed and optimized for all the candidate materials. This is a key prerequisite for the application of automatic data analysis, physical modelling and machine learning in objective 3 for EM and AFM methods.

3. Towards development of improved physical models of the output signals from nanoparticle size measurement systems, that accurately account for nanoparticle material, shape and quantity, with the final aim to improve the evaluation of nanoparticle measurement uncertainty and comparability between results of different methods.

The project has started using physical modelling of the signals and advanced data processing to extend the capabilities of methods for nanoparticle sizing and inter method comparison. More specifically, the project has started simulating elastic and inelastic scattering in electron microscopy. A complete algorithm has been implemented to generate simulated TSEM micrographs. For SEM, the program JMONSEL is used together with a second algorithm to properly determine nanoparticle dimensional properties. For AFM, a model for probe shape reconstruction has been established and for SAXS, a software tool for scattering simulation and shape reconstruction was created. In addition, first measurement results obtained with the methods from objective 1 are being processed with the PlatypusTM software to create a machine learning algorithm in order to automatically detect advanced nanoparticle shapes and extract features.

4. Towards the use of the new physical models to develop validated and traceable methods for the transfer of nanoparticle size from (certified) reference nanoparticles of spherical shape and monodisperse size distribution to other types of nanoparticles.

The newly developed physical models and machine learning algorithms from objective 3 will be validated using the reference nanoparticles developed in objective 2. The results will then be used to create new standard operation procedures for traceable nanoparticle size measurement for different nanoparticle shapes (such as elongated nanoparticles and platelets) as well as nanoparticles with non-monodisperse size distribution.

Impact

The project website has been developed and is available to stakeholders at: https://www.bam.de/Content/DE/Projekte/laufend/nPSize/npsize.html. A public workshop dedicated to current situation and future needs for reference nanomaterials was organised jointly by PTB and BAM at the start of the project. 111 experts from public institutes, academia, and industry, the JRC, DIN, ISO, CEN, EU and the Chief Stakeholder have participated. Four lectures and three posters were presented by project partners on improved measurement of nanoparticle size and shape. All contributions were compiled within the proceedings of the workshop, which have been published as a hard-copy report ‘NanoWorkshop 2018: Workshop on Reference Nanomaterials’. The project results were presented at international conferences including posters and talks (10 presentation). Additionally, two peer review publications are available on accurate analysis of particle size distribution for non-spherically shaped nanoparticles as quality control materials and of the nanoparticle number concentration.

Impact on industrial and other user communities

Representatives of manufacturers of nanomaterials attended the project’s public Workshop on Reference Nanomaterials. At the workshop the VCI (German Chemistry Industry Association) Chairman presented and discussed the needs expressed by this large industry association in terms of regulatory framework, development of measurement strategy at nanoscale, and European definition of nanomaterials. Stakeholder requirements were also systematically collected for use in the project. The consortium has links with instrument manufacturers such as Zeiss (a manufacturer of electron microscopes) and Xenocs (a manufacturer of X-ray based devices for nanomaterial characterisation), which will support prompt uptake of the project results by industry. In addition, the project has developed a framework on the Zenodo platform for a public database containing tagged electron microscopy (SEM, TEM and TSEM) images, AFM and SAXS measurement data from nanoparticle characterisation methods. Furthermore, a training course for stakeholders on the development of new reference nanoparticles is in progress. A Training course on Reference nanoparticles Production and Certification has taken place successfully at LGC (https://twitter.com/NML_ChemBioGC/status/1207582000313442304). The next Training Courses on accurate imaging of NPs and SAXS analysis are already in preparation for mid of 2020.

Impact on the metrology and scientific communities

The project will have direct impact on several metrology committees, especially the EURAMET Technical Committee for Length (TC-L), and the CIPM Consultative Committee for Length (CCL) Working Group on Nanometrology (WG-N). The in-depth evaluation of the performance of the traceable nanoparticle sizing techniques selected in this project will enhance the understanding of the physical processes involved in the signal generation and their dependence on shape and material variations. For the first time in a large research project both critical aspects, namely the lack of reference nanoparticles and signal modelling are systematically considered. Furthermore, the data fusion for hybrid methods will facilitate better knowledge of nanoparticle 3D size measurements.

The project partners have started disseminating the first results to the scientific nanoparticle characterisation community at conferences such as NANOSAFE 2018, Microscopy & Microanalysis 2019, Nanoscale 2019, ECASIA 2019 international conferences. Following recommendation by the Chief Stakeholder, the project has been presented at the 2019 International Congress of Metrology. Two manuscripts on individual materials developed in the present project were prepared and submitted for publication.

Impact on relevant standards

The project has the following links between project partners and national standardisation bodies; ISO/TC 229 (BAM, DIN, LGC), CEN/TC 352 (DIN, BAM, LGC) and ISO/TC 202 (BAM, PTB). The project has been presented to DIN NA 062-08-17 AA Nanotechnologies. A case study on the analysis of the size and shape distribution of TiO2 bipyramidal NPs by TEM was prepared by BAM, UNITO and PTB to be included into the ISO standard ISO/DIS 21363 Nanotechnologies — Measurements of particle size and shape distributions by transmission electron microscopy. This documentary standard is of special importance as the very first full ISO standard developed under ISO/TC 229 Nanotechnologies which is the pre-final stage to be likely published in the early 2020. With support from DIN, a project liaison between the present project with BAM as a coordinator and CEN/TC 352 has been applied for, was formally accepted by CEN, and the agreement contract is being prepared for signature. The project has also provided input to OECD (Organisation for Economic Cooperation and Development) Test 110 Guideline on Particle Size and Particle Size Distribution of Manufactured Nanomaterials.

Further to this, first positive discussions between the project and VAMAS and BIPM Consultative Committee for Amount of Substance (CCQM) have been made. Most likely the TiO2 nano-bipyramides (enough material is ensured) will be the material of choice for an inter-laboratory comparison to organised by BAM under VAMAS/TWA 34 ‘Nanoparticle population’. Also, the silica bimodal materials from CEA are good candidates.

Longer-term economic, social and environmental impacts

It is intended that the measurement capabilities for accurate size distribution of nanoparticles developed by this project will be transferred via normative documents, dedicated workshops and new reference nanoparticles to European large-scale manufacturers of nanoparticles, to service laboratories, and measurement instrument manufacturers. The new reference nanoparticles, improved signal modelling and data fusion offered by the project, will also contribute to metrological measurement capabilities to address the question of how to implement the EC definition of a nanomaterial. Furthermore, the project will contribute to the accurate identification of nanomaterials and nano-products and thus will provide a more reliable link to characterisation of potential toxic effect, environmental protection and safety will be improved.

List of publications

Nanoparticle size, shape, and concentration measurement at once – two VAMAS pre-standardization projects ready to start

Hodoroaba, V-D., Hörenz, C., Pellegrino, F., Maurino, V., Durand, B. and Tache, O.

2021

Microscopy and Microanalysis 27 (2021) , 2250-2251

Link to EURAMET

Influence of electron landing energy on the measurement of the dimensional properties of nanoparticle populations imaged by SEM

Crouzier, L., Delvallée, A., Devoille, L., Artous, S., Saint-Antonin, F. and Hodoroaba, V-D.

2021

Ultramicroscopy 226 (2021) , 113300

Link to EURAMET

The MOUSE project: a meticulous approach for obtaining traceable, wide-range X-ray scattering information

Smales, G.J. and Pauw, B.R.

2021

Journal of Instrumentation 16 (2021) , P06034

Link to EURAMET

Workflow towards automated segmentation of agglomerated, non-spherical particles from electron microscopy images using artificial neural networks

Rühle, B., Krumrey, J.F. and Hodoroaba, V-D.

2021

Scientific Reports 11 (2021) , 10

Link to EURAMET

Cuello-Nuñez, S., Abad-Álvaro, I., Bartczak, D., del Castillo Busto, M. E., Ramsay, D. A., Pellegrino and F., Goenaga-Infante, H., The accurate determination of number concentration of inorganic nanoparticles using spICP-MS with the dynamic mass flow approach. Journal of Analytical Atomic Spectrometry, 35 (2020) pp. 1832-1839.

DOI.org/10.1039/C9JA00415G

Hörenz, C., Tache, O., Bartczack, D., Nunez, S., Abad Alvaro, I., Goenaga-Infante, H., Hodoroaba, V.-D. A Study on the Analysis of Particle Size Distribution for Bimodal Model Nanoparticles by Electron Microscopy. Microscopy and Microanalysis Proceedings (2020), 1-3.

DOI.org/10.1017/S1431927620021054

Hodoroaba, V.-D., Cios, G., Tokarski, T., Mansfeld, U., Ortel, E., Mielke, J., Pellegrino, F., Maurino, V. Towards 3D Understanding of Non-spherical Nanoparticles by Transmission Kikuchi Diffraction (TKD) for Improved Particle Size Distribution by Electron Microscopy. Microscopy and Microanalysis Proceedings (2020), 1-3.

DOI.org/10.1017/S1431927620013999

Hodoroaba, V.-D., Rühle, B. Towards Automated Electron Microscopy Image Segmentation for Nanoparticles of Complex Shape by Convolutional Neural Networks. Microscopy. Microscopy and Microanalysis Proceedings (2020), 1-3.

DOI.org/10.1017/S1431927620017262

Pellegrino, F., Sordello, F., Mino, L., Prozzi, M., Mansfeld, U., Hodoroaba, V.-D., Minero, C. Polyethylene Glycol as Shape and Size Controller for the Hydrothermal Synthesis of SrTiO3 Cubes and Polyhedra. Nanomaterials 10 (2020), 1892, pp. 1-11.

DOI: 10.3390/nano10091892

Pellegrino, F., Isopescu, R., Pellutiè, L., Sordello, F., Rossi, A., Ortel, E., Martra, G., Hodoroaba, V.-D., Maurino, V. Machine Learning Approach for Elucidating and Predicting the Role of Synthesis Parameters on the Shape and Size of TiO2 Nanoparticles. Scientific Reports (2020), pp. 1-11.

DOI.org/10.1038/s41598-020-75967-w

Characterization of Nanoparticles: Measurement Procedures for Nanoparticles, Elsevier, Editors: Hodoroaba, V.-D., Unger, W. E. S., A.G. Shard, A. G.

ISBN: 978-0-12-814182-3;

DOI.org/10.1016/C2017-0-00312-9

Mansfeld, U., Pellegrino, F., Maurino, V., Marguet, S., Testard, F., Tache, O., Hodoroaba, V.-D. Towards Accurate Analysis of Particle Size Distribution for Non-Spherically Shaped Nanoparticles as Quality Control Materials. Microscopy and Microanalysis 25 (2019), 2328-2329.

DOI.org/10.1017/S1431927619012376

Klein, T., Hodoroaba, V.-D., Dziomba, T., Buhr, E., Bosse, H. and Krumrey, M. NanoWorkshop 2018: Workshop on Reference Nanomaterials; Current Situation and needs: development, measurement, Standardization. PTB Bericht F-61 (2018), 1-315.

https://oar.ptb.de/resources/show/10.7795/110.20190412

Partners

BAM Bundesanstalt für Materialforschung und -prüfung (BAM), Germany

LGC National Measurement Laboratory, UK

LNE Laboratoire National de métrologie et d'Essais, France

PTB Physikalisch Technische Bundesanstalt, Germany

VSL Dutch Metrology Institute, The Netherlands

CEA Le Commissariat à l’énergie atomique et aux énergies alternatives, France

DIN Deutsches Institut für Normung, Germany

POLLEN Institute, France

UNITO L'Università di Torino, Italy

SMD Service Metrologie Metrologische Dienst, Belgium

Coordination: Dr. Vasile-Dan Hodoroaba, Bundesanstalt für Materialforschung und -prüfung (BAM)

Funding

This project receives funding from the European Metrology Programme for Innovation and Research (EMPIR) which is an integrated part of Horizon 2020, the EU Framework Programme for Research and Innovation.

Source: EMPIR