Laser beam source and laser-induced plasma on the surface of a TIG-welded duplex stainless steel sample

Source: BAM

Project period

01/12/2020 - 21/11/2023

Project type

Project status

Closed

Description

Project objectives: Increase the predictive accuracy of the weld microstructure of modern steels. Furthermore, the burnoff behavior of alloying elements of high-strength steels is to be monitored in situ.

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

Lukas Quackatz during measurement preparation Source: BAM

Modern steels exhibit microstructural changes during welding that result to uneven phase ratios and changes in chemical composition. Microstructural changes can lead to solidification cracks, increase in susceptibility to corrosion, lower ductility and critical strength values. Laser-induced breakdown spectroscopy (LIBS) enables time- and spatially-resolved in situ measurement of both temperature and chemical composition during welding.

Source: BAM

Source: BAM

LIBS is a spectroscopic method that can be used to determine elemental compositions. Short, high-energy laser pulses ablate a small volume (< 0.1 mm3) of the bombarded material and ionise it to form a plasma. The decayed plasma emits element-specific light. The simple experimental set-up and the fast, non-destructive analysis procedure characterize the LIBS analysis. Elemental analyses can be performed without contact and without pretreatment of the samples. Liquid as well as solid and gaseous substances can be analyzed.

Source: BAM

Funding

The project is funded by the German Research Foundation (DFG), project number 442001176.

insituLIBS - In situ investigation of phase distribution and melt pool solidification of duplex stainless steels using laser-induced breakdown spectroscopy (LIBS)

Weld seam monitoring

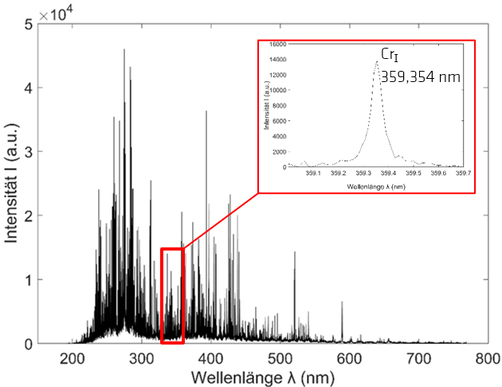

Laser-induced breakdown spectroscopy (LIBS) offers a promising option for in situ weld monitoring. In LIBS analysis, a high-energy pulsed laser generates a plasma on the material surface. The expansion of the plasma causes electromagnetic radiation. This radiation is element specific and can be used to chemically characterize the tested material after a reference analysis. The solidification sequence of the material correlates directly with the temperature in the molten bath. Therefore, it is necessary to monitor this temperature in the welding process to make immediate parameter adjustments. By calculating electron temperatures in the laser plasma, the temperature can be determined with time and spatial resolution without additional measuring equipment. Following the measurement process, spectra are generated and evaluated for each individual measurement point. After subtraction of the background radiation, the intensities of the elements of interest can be filtered out.

LIPS spectrum of a duplex stainless steel 1.4162 with visualisation of a characteristic chrome line

Source: BAM

Project coordination

Bundesanstalt für Materialforschung und -prüfung (BAM)

Division Weld Mechanics

Funding

The project is funded by the German Research Foundation (DFG), project number 442001176. DFG-Logo Source: DFG