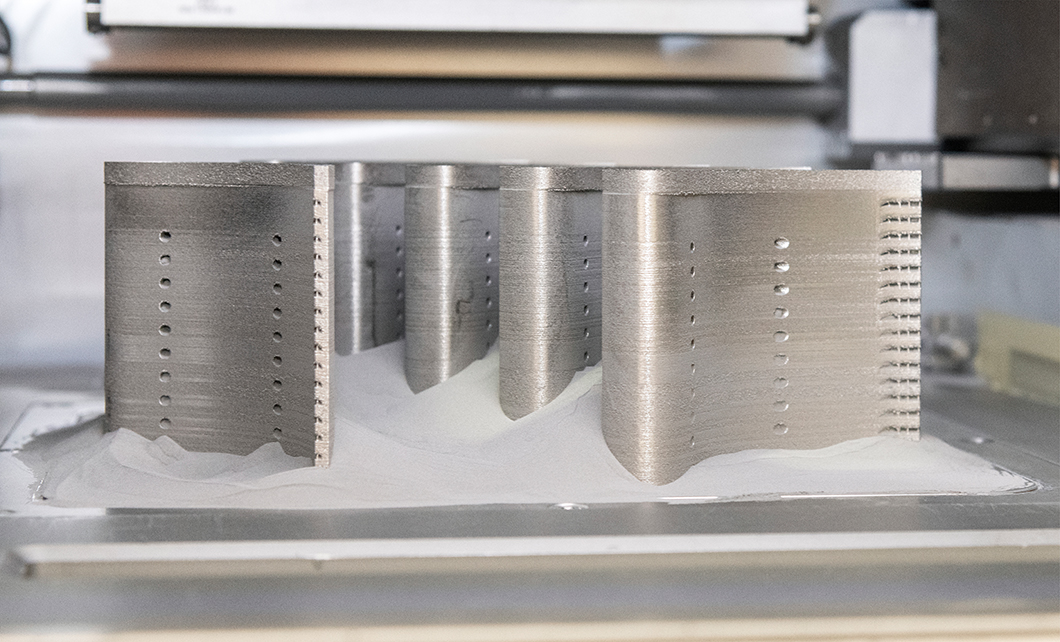

Additive manufacturing of turbine blades from a nickel base superalloy

Source: BAM

Project period

01/01/2023 - 30/06/2025

Project type

Collaborative research project

Project status

Ongoing

Description

The aim of the project HTA 2.0 (2nd phase) - Sustainable Additive Manufacturing for High Temperature Applications - is to increase the usability and sustainability of additively manufactured high-temperature components in gas turbine industry.

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Unter den Eichen 87

12205 Berlin

HTA 2.0 - High Temperature Applications

Challenge

The project HTA 2.0 - Sustainable Additive Manufacturing for High-Temperature Applications directly follows the successful first project phase of HTA 2.0 - High-Temperature Applications. In the second funding period, the portfolio of AM technologies for gas turbine components will be expanded by two additional processes, this time with a focus on faster and more efficient processes. New strategies for the post-processing of components produced by powder bed based additive manufacturing (AM) will close the loop with the main aim of reducing material waste and minimising process times. The result will be an overall view of which AM technology is more sustainable for which component as a whole. In the end, it is not a matter of adapting the component to the technology, but vice versa.

Objectives

The research project aims to evaluate additive manufacturing processes in the context of sustainable product development and to identify more economically and ecologically efficient component solutions for the area of high temperature gas turbine components. The increase in material reusability and the exploitation of previously unexploited potentials of additive manufacturing processes, as well as the improvement of post-processing strategies and procedures, should contribute to this. To achieve this, material, production and design must be optimally harmonised and targeted digitalisation solutions must be integrated into product development.

Method

In order to be able to evaluate additively manufactured components for high-temperature applications in the context of sustainable product development, it is important to have extensive knowledge about the processability of high-temperature materials, the interaction between product design, manufacturing process and post-treatment, as well as the behaviour of the materials in application. BAM contributes to this with its expertise in comprehensive material characterisation, additive manufacturing process, process monitoring and determination of material behaviour at high temperatures.

View into the Laser Powder Bed Fusion process

Source: BAM

BAM's contribution

Quality assurance of AM components by means of CT

BAM Department Micro Non-Destructive Testing, Dr. Tobias Fritsch

Mechanical-technological long-term behaviour of AM components

BAM Department Materials Modelling, Dr. Bernard Fedelich

Process parameter development for the DED-Arc/M process

BAM Department Welding Technology, Dr. Andreas Pittner

Influences of preheating on the PBF-LB/M process and the resulting properties

BAM Department Additive Manufacturing of Metallic Components, Dr. Gunther Mohr

Influences of the PBF-LB/M process on powder degradation

BAM Department Additive Manufacturing of Metallic Components, Dr. Gunther Mohr

Process development of electron beam welding of AM components

BAM Department Additive Manufacturing of Metallic Components, Dr. Gunther Mohr

Residual stress analysis of AM components

BAM Department Weld Mechanics, Dr. Arne Kromm

Project coordination

Bundesanstalt für Materialforschung und -prüfung (BAM)

Division Additive Manufacturing of Metallic Components

Partners

Siemens Energy Global GmbH & Co. KG

Technische Universität Berlin (verschiedene Lehrstühle)

Fraunhofer IPK (Fraunhofer-Institut für Produktionsanlagen und Konstruktionstechnik)

Funding

The project is carried out within the Werner-von-Siemens Centre for Industry and Science. It is funded by the Investitionsbank Berlin (ProFIT) and co-financed by the European Regional Development Fund (ERDF).

Logo of the Werner-von-Siemens Centre for Industry and Science

Source: WvSC

Logo of the EU European Regional Development Fund

Source: EU