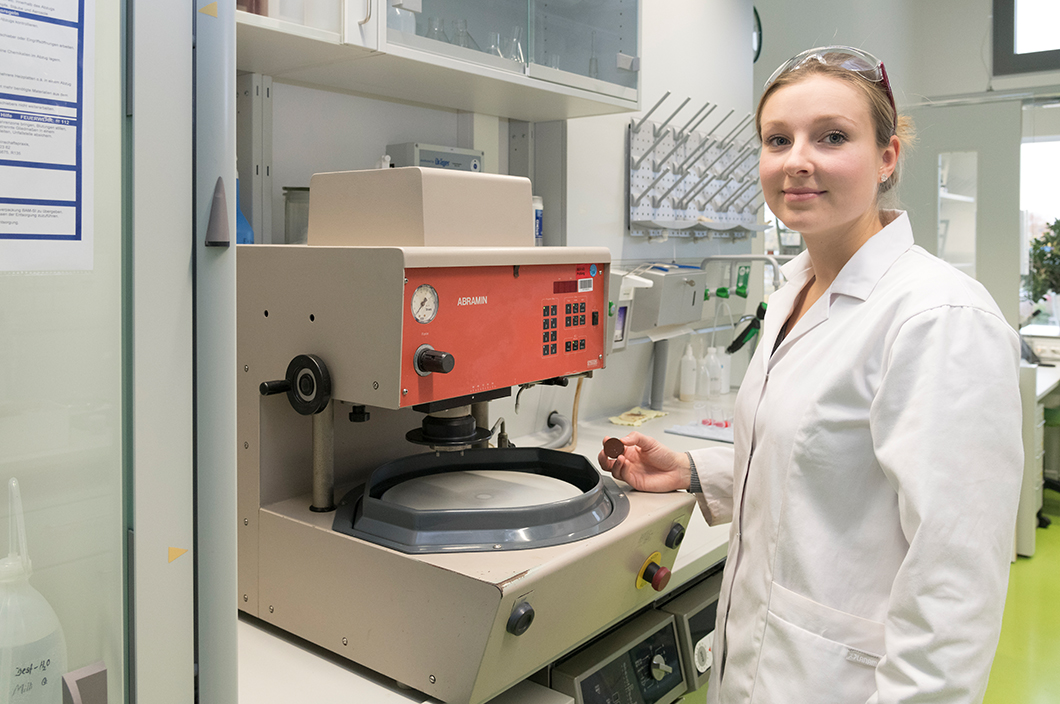

Ms. Marie Hoffmann during sample preparation for the SCALE project: Preparation of thick sections for investigation of mineral chemistry and mineralogy with different (electron-)microscopy methods

Source: BAM

Project period

01/12/2016 - 30/11/2020

Project type

Collaborative research project

Project status

Closed

Description

The SCALE project involves innovative technologies for the efficient extraction of Scandium (Sc) from industrial byproducts, such as red mud (bauxite residue). BAM will develop an inventory of industrial by-products containing Scandium.

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Richard-Willstätter-Straße 11

12489 Berlin

Laboratory flask containing synthetic goethite Source: BAM

Source: BAM

Innovative and selective methods are to be developed for two different metallurgical by-products with the aim of commercial production of Scandium concentrate (at least 20 wt %). The Scandium concentrate is to be refined to Sc2O3and to ScF compounds (at least 99% purity) using innovative technologies. Other aims are to assess the sustainability of the technologies developed and to prepare the scientific foundations for a future European Scandium industry.

Source: BAM

Source: BAM

Funding

The projects receives funding from the EU Horizon 2020 Programm

Grant Agreement no 730105

Total costs: 7.706.625 €

Amount of EU funding: 7.000.000 €

Coordination

AoG - Aluminium of Greece

Partners

17 partners from EU countries

SCALE - Production of Scandium compounds and Sc-Al alloys from European metallurgical by-products

Scandium is currently one of the costliest elements on the market and has been classified as a critical raw material since 2017. An efficient process for (re-)obtaining and producing it is therefore one of the main research and business interests on the European Union agenda.

Progress in technology and new advances in material sciences are closely linked to the availability of metals and alloys. The focus in recent years has shifted more and more to the so-called technology metals in particular. These include rare-earth elements (REE), Indium, Germanium, Gallium, Lithium, Platinum group metals, Niobium, etc. Even in low concentrations, they have a major influence on certain material properties.

The aim of the SCALE project is to establish a closed supply chain for Scandium in Europe. The use of industrial by-products, which now are mostly disposed and stockpiled, is an essential factor and contributes to the “circular economy” approach adopted by the European Union. Another aim is to counteract the general dependency of Europe on individual countries like China in the market for rare-earth elements and technology metals.

Inventory of industrial by-products containing Scandium

BAM is preparing the inventory of industrial by-products containing Scandium in the “Networking and Clustering” work package. One of the tasks is the mineralogical and chemical characterization of by-products treated in the project (primarily red mud and Titanium dioxide production residues). Another aim is the identification and characterization of further industrial residues which may potentially contain Scandium. The results of these investigations are to be integrated into a European raw materials database. BAM will investigate the Scandium species contained in the two main residues included in the study, the nature of the connection to the primary raw material, and the potential influence of the bonding form on the hydrometallurgical extraction process.

Sample preparation: Polishing of red mud thick section Source: BAM

Coordination

AoG - Aluminium of Greece, Greece

Partners

BAM - Bundesanstalt für Materialforschung und -prüfung (BAM), Germany

Io-Li-Tech - Ionic Liquids Technologies, Germany

AOS - Aluminium Oxidstade GmbH, Germany

II-VI Performance Metals, Deutschland GmbH, Germany

BME - Budapest University of Technology and Economics (BME), Hungary

FHNW - Fachhochschule Nordwestschweiz, Switzerland

Fraunhofer ISC - Fraunhofer Gesellschaft zur Förderung der angewandten Forschung e.V., Germany

LCM - Less Common Metals Ltd., UK

ITRB - ITRB Group, Cyprus

NTUA - The National Technical University of Athens, Greece

MEAB - MEAB Chemie Technik GmbH, Germany

KBM - KBM Affilips Master Alloys, the Netherlands

WAFESTONE - Wafestone, Luxemburg

RWTH Aachen - Rheinisch-westfälische Technische Hochschule Aachen, Germany

KTH - Kungliga Tekniska Hoegskolan, Sweden

SINTEF - Stiftelsen Sintef, Scandinavia

TRONOX - Tronox Pigments, the Netherlands