Source: SH2APED

Project period

01/01/2021 - 30/09/2024

Project type

EU project

Project status

Closed

Description

The SH2APED project aims at the development of an efficient tubular tank element and the entire system under internal pressure of 70 MPa with drastically improved fire and mechanical resistance and with a reduction of carbon fibre use and winding time compared to the state-of-the-art Type IV tanks.

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

Source: SH2APED LinkedIn

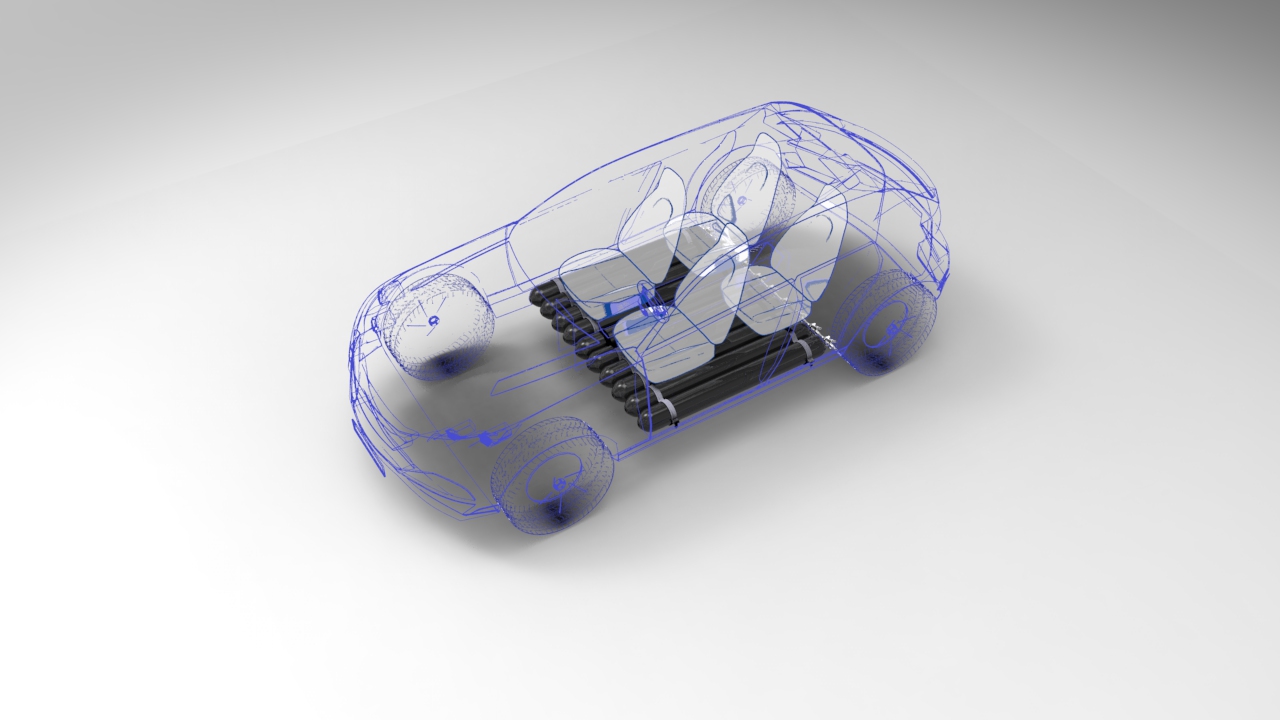

The SH2APED project focuses on the development of a competitive and innovative European hydrogen storage system to outperform the current state-of-art Type IV tank technology. An assembly of tubular pressure containments will be developed as a modular system, easily configurable for any given design space and breakthrough safety feature to exclude rupture in a fire even in conditions of failed TPRD (Thermal Pressure Relief Device).

Source: BAM

The SH2APED project aims to develop and test an innovative storage system fitting into a design space used for the battery pack in the flat space of light-duty car underbodies. Fire resistance and mechanical robustness are drastically improved while the cost is decreased by 20%. Objectives: 1) Design of a hydrogen 70 MPa tank system 2) Technical, safety and performance validation 3) Economic assessment for industrial mass manufacturing 4) Contribution to safety and standards

Source: BAM

SH2APED is an inter-disciplinary project with the participation of experts in composite hydrogen storage technologies, hydrogen safety, CFD simulation, experimental techniques. The project contains four main activities 1) modular storage system development, 2) components and subcomponents, 3) Efficiency and safety performance, 4) Fire resistance. BAM contributes with the expertise of testing and safety probabilistic assessment.

Source: BAM

Projektkoordination: Plastic Omnium Mobility, Belgium

Partners: 4 European partners from industry, academia and research institutes

Funding: The project receives funding from the European Research and Innovation action (RIA) via the Horizon2020 Framework Programme, Topic: FCH-01-1-2020 - Development of hydrogen tanks for electric vehicle architectures (Call H2020-JTI-FCH-2020-1), Grant agreement ID: 101007182

Safe onboard storage is clearly one of the greatest challenges for the hydrogen economy. Even if hydrogen vehicles offer better efficiency, technological barriers remain for short-term implementation. Hydrogen storage difficulties stem from its low density, necessitating very high pressure for storage. In addition, the weight, volume, efficiency, safety of storage as well as the cost of the hydrogen must be considered. Safety is of paramount importance for deployment of hydrogen technologies as it is flammable in a wide range of concentrations with air, more sensitive to ignition due to its low minimum ignition energy, deflagrates faster due to higher burning velocity, and is prone to deflagration-to-detonation transition. Various safety measures must be implemented in order to prevent accidental leakage and ensure inherent safety.

Today, the strategy of the OEM’s prioritises the development of a single electrical drivetrain platform where the battery pack is mounted in the underbody of the vehicle. The automotive industry aims to use this same space for hydrogen storage systems, with the expectation that such conformable hydrogen storage systems will be available in the next 3-5 years.

The main innovations of BAM’s specialist divisions 3.5 and 8.6 in this project are, firstly, the integration of optical fibres in the filament winding of complete pressure to gain a deeper understanding of the structural behaviour under the different hydraulic and pneumatic loading conditions, and secondly, the development of a fire test platform to test the assembly of 9 tubular vessels under the fire test requirements of GTR13. Therefore, a wind damping and splinter-protecting cage was built from protection modules specifically developed for this project. Extensive safety-related tests are to be carried out at BAM during the project period.

Partner

The project receives funding from the European Research and Innovation action (RIA) via the Horizon2020 Framework Programme, Topic: FCH-01-1-2020 - Development of hydrogen tanks for electric vehicle architectures (Call H2020-JTI-FCH-2020-1), Grant agreement ID: 101007182

Plastic Omnium New Energies (PONE), Belgium

OMB Saleri S.p.A., Italy

Bundesanstalt für Materialforschung und -prüfung (BAM), Germany

University of Ulster, United Kingdom

Source: BAM

Funding

The project receives funding from the European Research and Innovation action (RIA) via the Horizon2020 Framework Programme, Topic: FCH-01-1-2020 - Development of hydrogen tanks for electric vehicle architectures (Call H2020-JTI-FCH-2020-1), Grant agreement ID: 101007182