The aim of the project PHOENIX is a concept for a new generation of climate-neutral hydrogen engines for industrial use.

Source: Rolls-Royce

Project period

01/01/2024 - 31/12/2026

Project type

Collaborative research project

Project status

Ongoing

Description

In the collaborative research project PHOENIX, a concept for an efficient hydrogen combustion engine for cogeneration plants is to be developed and the corresponding evidence provided. Among other things, BAM is developing methods to qualify lubricants regarding their tendency to pre-ignite and their tribological properties in the hydrogen engine. For this purpose, tests are carried out in hydrogen environments.

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

Facility to compensate for fluctuations in the power grid Source: Rolls-Royce

Source: BAM

Source: BAM

Source: BAM

Partners:

Rolls-Royce Solutions GmbH

Bundesanstalt für Materialforschung und -prüfung (BAM)

FUCHS Lubricants GERMANY GmbH

MAHLE Industriemotoren-Komponenten GmbH

Technical University of Munich, Institute of Sustainable Mobile Powertrains

Associated partner: Bosch division Large Engine

Funding: Federal Ministry for Economic Affairs and Climate Action

Compared to gas turbines, efficient gas engines can start up very quickly and operate in different load ranges. Therefore, they are very suitable for use in flexible decentralized gas power plants to compensate for fluctuations in solar and wind energy. Consequently, if they are operated with green hydrogen, they are a key element in accelerating the energy transition.

In the project PHOENIX (Performance Hydrogen Engine for Industrial and X), a concept for a high-performance hydrogen engine, including the associated components, is being developed for use in industrial applications for stationary energy supply. The project is being funded by the Federal Ministry for Economic Affairs and Climate Action with a total of almost five million euros.

In order to investigate different aspects of the hydrogen engine in the best possible way, the project is being carried out by a consortium of highly specialized industrial companies and scientific institutions. The consortium partners are developing the necessary components such as the injection system, the piston assembly and the ignition system as well as a lubricant specially optimized for the combustion of hydrogen. BAM is providing the PHOENIX project with its many years of expertise in the fields of hydrogen safety and tribology.

Development of lubricants for the hydrogen engine

The BAM part of this project “Influence of lubricants on the ignition of hydrogen-air mixtures and their tribological characterization” aims to develop and apply methods for the qualification of suitable lubricants for hydrogen engines.

Due to the low ignition energy of hydrogen in combination with its wide explosion range, the propensity for pre-ignition in hydrogen engines is higher than in natural gas engines when lubricant is introduced. Pre-ignition can lead to high pressure peaks in the engine and to unstable operating conditions, which in the worst case can even result in irreparable engine damage. In close cooperation with the consortium partners, lubricant formulations with high resistance to pre-ignition are being developed. To reduce the need for complex tests on the engine test bench, BAM is developing a simplified test procedure for investigating the ignition behavior of various lubricants in a hydrogen atmosphere under engine-like conditions. A test setup with pressure-resistant autoclaves is being established and used for this purpose. The results will be validated on the engine test bench of the project partners and the test procedure will be optimized if necessary.

In addition, the possible influence of catalytic surfaces on pre-ignition is being investigated. For this purpose, surfaces of various materials used in hydrogen engines are tested in a modified autoclave test setup regarding their catalytic properties. Subsequently, their suitability for use in hydrogen engines is assessed.

The test setup with pressure-resistant autoclaves

Source: BAM

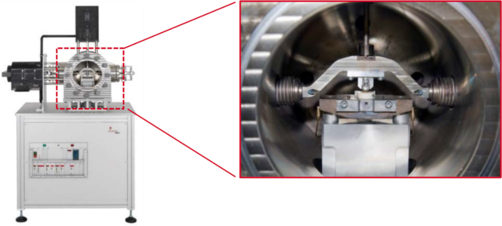

The lubricant should also have sufficient resistance to water ingress from hydrogen combustion, minimize wear and hydrogen ingress into the materials and ensure good lubrication. In this context, the tribological properties of the lubricant are characterized in special test facilities. A new test facility is being set up at BAM where the tribological properties of the lubricants can be investigated directly in a hydrogen atmosphere under conditions close to the engine.

Test chamber constructed by BAM for a tribometer

Source: BAM

Project lead

Project partners

Bundesanstalt für Materialforschung und -prüfung (BAM): Division 2.1 und Division 9.5

FUCHS Lubricants GERMANY GmbH

MAHLE Industriemotoren-Komponenten GmbH

Technical University of Munich, Institute of Sustainable Mobile Powertrains

Associated project partner

Bosch division Large Engine

Funding

The project is funded by the Federal Ministry for Economic Affairs and Climate Action in the 7th Energy Research Program of the Federal Government in the funding area of sector coupling and hydrogen technologies.