José Villajos at BAM's test stand for high-pressure adsorption of hydrogen in MOFs at cryogenic temperatures between 77 and 100 K

Source: BAM

Project period

01/09/2020 - 31/08/2023

Project type

EU project

Project status

Closed

Description

MefHySto addresses the need of large-scale energy storage, which is required for a shift to renewable energy supply. Metrological traceability in the energy infrastructure for hydrogen storage is crucial and a better knowledge of the chemical and physical properties of hydrogen as well as traceable measurements and validated techniques are indispensable.

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Richard-Willstätter-Straße 11

12489 Berlin

Source: MefHySto

Source: BAM

Source: BAM

Cavity ring down spectroscopy (CRDS); online trace humidity dynamics: SAW, metal oxide dew point probe, fibre optics, high pressure dew point mirror, electrolytic; reference humidity generator and reference hygrometer; spherical microwave resonator; preparation and investigation of high-precision reference gas mixtures; measurement of volumetric and gravimetric storage capacity; thermodynamics of adsorption/absorption and desorption; measurement methods for hydrogen quality and flow; measurement methods for flow, moisture or gas quality of hydrogen.

Source: BAM

Coordination

Bundesanstalt für Materialforschung und -prüfung (BAM)

Consortium

14 international partners from science and industries

Funding

MefHySto is funded through the European Metrology Programme for Innovation and Research EMPIR, Grant ID: 10.13039/100014132, Grant number: 19ENG03 MefHySto.

MefHySto - Metrology for advanced hydrogen storage solutions

Motivation and background

Renewable energy sources fluctuate significantly and large-scale storage of hydrogen is a promising solution to avoid interruptions in energy supply. Depending on the quantity, the availability for conversion into energy and the required purity, three different types of hydrogen storage are currently used: 1. medium-scale, safe, reversible storage in solids by hydrides or cryo-adsorption in porous media, 2. injection into the natural gas grid and 3. underground storage in geological cavities. Reliable standards, reference methods and materials are needed for these three types of storage.

Also, new techniques such as power-to-hydrogen, power-to-gas or gas-to-power need to be further investigated, as the intermittent operation of a water electrolysis cell to convert electric current into hydrogen leads to frequent start-stop phases with inherent, unstable, predefined idle conditions. Impurities can lead to significant performance losses in fuel cells during the conversion of hydrogen into electric current. Therefore, a detailed and systematic investigation of the effects of compounds/impurities on the performance of fuel cells under cyclic loading is required to improve their lifetime.

The prerequisites for a successful energy transition and the economic use of hydrogen as a clean, green energy carrier are H2 readiness and a rapid market introduction, as well as the establishment of the necessary value chains within a European framework. The feasibility of almost all hydrogen economy technologies has been proven, and some are even very advanced. A major challenge, however, is the scaling of these technologies to previously unimaginable technical scales, which are completely new to everyone and in their interaction.

Particularly noteworthy here are the production of green hydrogen and its storage on an enormously large scale. The MefHySto project has dedicated itself to these tasks along the hydrogen storage value chain in five technical work packages and will publish the work results as soon as possible.

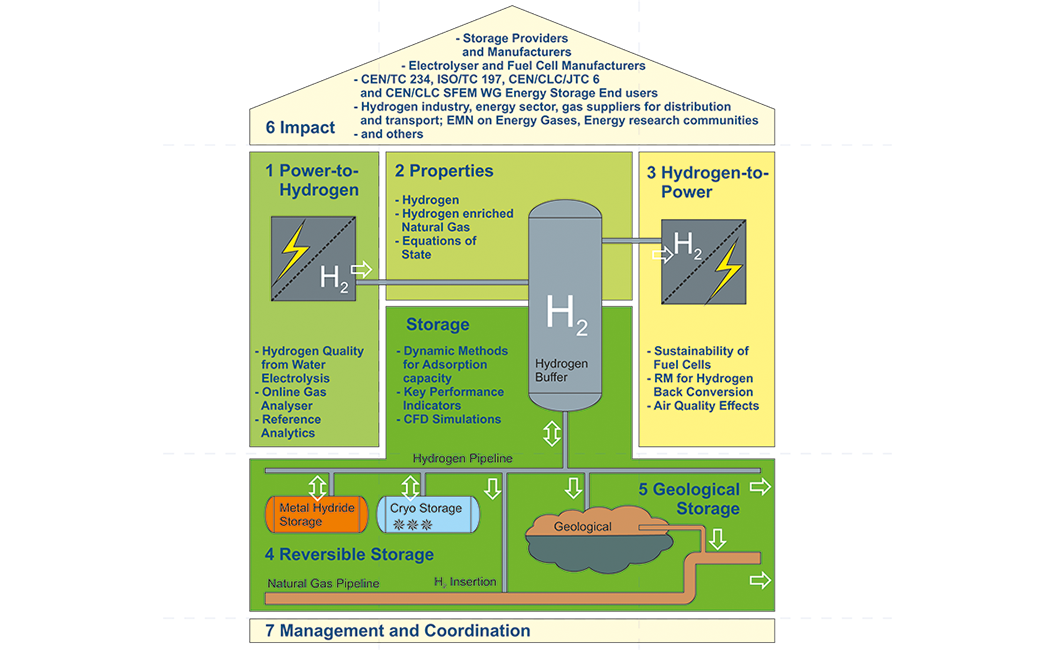

Overview of the MefHySto project

Source: MefHySto

Aims and work packages

- Evaluation of the quality of hydrogen produced by PEM water electrolysis during rapidly imposed transition periods

In general, electrolysis is currently well understood. However, detailed investigations of energetic processes and load conditions are still lacking. This also applies to short-term peak energy loads of up to 200 %, which must be handled safely to avoid quality problems or damage to fuel cells (FCs) and peripheral equipment. The project investigates the quality of hydrogen produced from proton exchange membrane water electrolysis during rapidly imposed transient periods of use. This is done with online gas analysers, which are used to measure important impurities such as water vapour and oxygen. This project will develop new measurement techniques for measuring key impurities, new facilities and tests of instrument response time under transient load and conditions relevant to different storage modes. The extended measurement range, the mixed gas matrix and especially the transient conditions pose challenges.

- Improvement of the reference equations of state as a basis for the precise determination of the calorific values of energy gases

Precise knowledge of the thermodynamic properties of natural gases and hydrogen-enriched natural gases is of indispensable importance for the fundamental design and implementation of technical processes and their engineering. The processing, transport by pipeline or ship, storage and liquefaction of natural gas are examples of technical applications where the thermodynamic properties of different mixtures of natural gas components are needed as early as possible in order to optimise the design at market introduction. To determine the commercially significant calorific value and to calculate the thermophysical properties, the European Gas Research Group (GERG)-2008 equation of state (EoS) is the accepted ISO standard (ISO 20765-2). However, the composition of natural gas can vary considerably due to its different origins, which makes it difficult to determine the calorific value and thermophysical properties. Therefore, the GERG-2008 EoS needs to be extended to the scope for diversification, e.g. by adding hydrogen. Thus, high-precision experimental data on pressure, mass density and temperature (p, ρ, T) for gravimetrically produced synthetic natural gas mixtures are provided in MefHySto.

- Investigating the sustainability and reliability of fuel cells (FCs) and their performance due to impurities in the hydrogen and air

The reconversion of hydrogen into electrical energy by a FC is seen as a potential solution to generate carbon-free energy for both stationary and mobile applications. This project will provide valuable information on the performance and durability of FCs under realistic operating conditions at single cell and stack level to quantify the impact of impurities in hydrogen and air (based on existing standards). A focus will be on new key halogen compounds as well as impurity combination effects (sequential or simultaneous) on FC response using a differential cell to in-situ characterisations by current density mapping on stacks. NOx and SOx contaminants in the air are also investigated to assess individual and combined effects on FC operation. Such coupling effects have rarely been studied so far.

- Harmonised methods for reversible hydrogen storage

In recent years, research has investigated many potential materials for H2 storage, such as metal hydrides for absorption or cryogenic adsorption at temperatures up to liquefied nitrogen, in which near-liquid H2 storage densities can be achieved (even higher). Processes for reversible solid-state storage that make larger quantities of H2 available again in pure form are enormously important building blocks in a circular hydrogen economy, especially for the use of fuel cells.

However, reversible hydrogen storage in metal hydrides and porous materials (cryostorage) requires accurate knowledge of adsorption capacity as a function of pressure and temperature, thermal parameters during adsorption/absorption and desorption in dynamic operation. This project will standardise the methods and protocols for reliable characterisation of metal hydrides and porous materials (cryostorage) and do so for the key performance indicators for metal hydrides and porous materials, such as volumetric and gravimetric storage capacity and the thermodynamics of adsorption/absorption and desorption. The project will also develop traceable methods for characterising storage materials and reference standards for capacity measurements and for testing the influence of gas impurities.

- Solving metrological and thermodynamic issues in the large-scale storage of hydrogen in underground gas storage (UGS) and in the conversion of existing UGS from natural gas to hydrogen.

Geological reservoirs are of enormous importance because of their potentially high storage capacity. Unfortunately, there is little public information available so far, as many projects to convert existing natural gas storage facilities or to build new hydrogen storage facilities are organised by the private sector and are just starting up. It is also important to distinguish between two types of storage: Pore storage and caverns. In caverns, conversion to high H2 contents can be achieved quickly, whereas pore storage facilities have to be converted over long periods of time. The metrological and analytical requirements are correspondingly different. A significant number of new UGS is not expected at present. Public funds (project funding) are currently being obtained for the conversion of caverns to hydrogen. In addition, investigations and assessments of the material are currently being carried out at various storage facilities to determine the possibilities and costs of conversion. H2 admixtures to natural gas, but also pure H2 caverns are being considered. The bottleneck seems to be the availability of large quantities of hydrogen.

Methods

- Cavity ring down spectroscopy (CRDS) for trace humidity

- Online trace humidity dynamics (loan hygrometer from manufacturers with five different measurement principles: SAW, metal oxide dew point probe, fibre optics, high pressure dew point mirror, electrolytic)

- Reference humidity generator and reference hygrometer

- Spherical microwave resonator for high precision measurements of hydrogen thermophysical properties

- Preparation and investigation of a series of high-precision reference gas mixtures to fill gaps in the literature for hydrogen and its mixtures (known 11-component natural gas and 0, 10 and 20 % hydrogen respectively, and a series of three binary mixtures (propane + hydrogen) with propane contents of 5, 10 and 17 %)

- Apparatus for measuring volumetric and gravimetric storage capacity and for the thermodynamics of adsorption/absorption and desorption

- Measurement methods for hydrogen quality and flow

- Technical measurement methods for flow, moisture or gas quality of hydrogen.

Project coordination

Bundesanstalt für Materialforschung und -prüfung (BAM)

Process Analytical Technology division

Project partners

BAM Bundesanstalt für Materialforschung und -prüfung

CMI Cesky Metrologicky Institut, Czech Republic

NPL Nationa Physocal Laboratory, United Kingdom

PTB Physikalisch-Technische Bundesanstalt, Germany

CEA Commissariat à l’Énergie Atomique et aux Énergies Alternatives, France

DBI DBI GAS UND UMWELTTECHNIK GMBH, Germany

DVGW Deutscher Verein des Gas- und Wasserfaches - Technisch-wissenschaftlicher Verein e.V., Germany

ERIG European Research Institute for Gas and Energy Innovation, Belgium

FHA Fundacion para el desarrollo de las nuevas tecnologias del Hidrogeno en Aragon, Spain

MAHYTEC MAHYTEC SAS, France

MPG Max Planck Institut für Intelligente Systeme Stuttgart, Germany

Reganosa Regasificadora del Noroeste, S.A, Spain

UDC Universidade da Coruña, Spain

UVa Universidad de Valladolid, Spain

Funding

Special thanks to the European Metrology Programme for Innovation and Research EMPIR (Grant ID: 10.13039/100014132, Grant number: 19ENG03 MefHySto) for funding the project.

Source: EMPIR