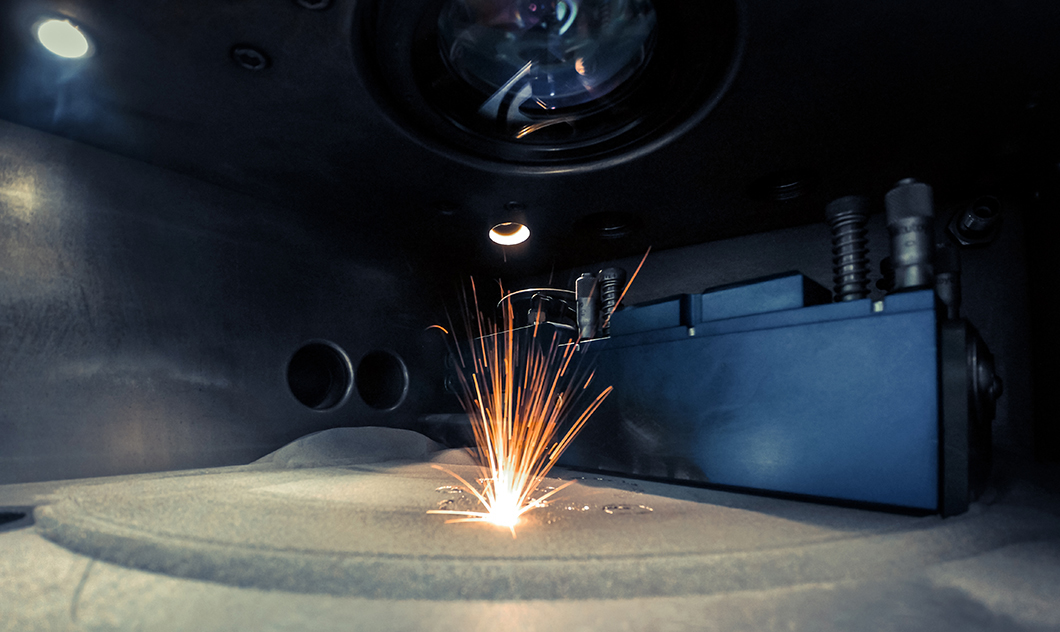

A 3D printer that prints metal. Metal is sintered into shape under the influence of a laser.

Source: iStock

Project period

01/01/2023 - 31/12/2024

Project type

Collaborative research project

Project status

Ongoing

Description

The aim of the "MRO 2.0 - Maintenance, Repair & Overhaul, phase II" project is to develop new technologies for maintenance and repair activities in an expediently automated refurbishment process chain, including the upgrade for high-efficiency gas turbines.

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

In the newly built production hall of Siemens Energy, research will in future be conducted on repair and maintenance topics. Source: Werner-von-Siemens Center

Source: BAM

Source: BAM

Review: MRO 2.0 - Maintenance, Repair & Overhaul – phase 1

The "MRO 2.0 - Maintenance, Repair & Overhaul" project began in 2020. The first phase (01.07.2020 - 31.12.2022) focused on developing new technologies for maintenance and repair activities that simultaneously represent an upgrade, i.e. an improvement in the properties of the component. Improved properties in turn lead to higher efficiency and lower emissions.

The use of future technologies such as digital solutions or additive manufacturing processes can lead to product and process innovations that enable longer operating intervals. Within the framework of the Werner von Siemens Centre, components, systems and machines will no longer be repaired in the classic way, but will be equipped with better properties through new technologies during the repair process: Upgrade instead of Repair. Maintenance, Repair and Overhaul refers to the classic maintenance and repair business with which components, systems and machines are overhauled. Typically, this is done through static repair process chains in which the same value-adding steps are carried out continuously. After repair or maintenance, the plant and machinery continues to operate with identical characteristics.

BAM's contributions in phase 2

CAx chain for the repair of moving blades by wire arc process

Dr. Andreas Pittner, Welding Technology Division

Water vapor resistance of ceramic materials for combustion chambers

Artur Göbel, Materialography, Fractography and Ageing of Engineered Materials Division

Development of a quality tool for in-situ process monitoring of additive manufacturing in the powder bed processes

Dr.-Ing. Kai Hilgenberg, Additive Manufacturing of Metallic Components Division

Damage and measure prediction

Dr. Jürgen Olbricht, Experimental and Model Based Mechanical Behaviour of Materials Division

Determination of wall thickness of turbine blades

Dr.-Ing. Jens Prager, Acoustic and Electromagnetic Methods Division

Detection of cracks of turbine blades

Dr. Mathias Ziegler, Thermographic Methods Division

Project coordination

Dr.-Ing. Jens Prager, Bundesanstalt für Materialforschung und -prüfung (BAM)

Partners

Siemens Energy Global GmbH & Co. KG

Technische Universität Berlin

Fraunhofer Institute for Production Systems and Design Technology

KleRo GmbH Roboterautomation

GESTALT Robotics GmbH

YOUSE GmbH

Datalyze Solutions GmbH

SERVITIZE UG

CONTACT Software GmbH

Funding

The project is carried out within the Werner-von-Siemens Centre for Industry and Science. It is funded by the Investitionsbank Berlin (ProFIT) and co-financed by the European Regional Development Fund (ERDF).

Logo of the Werner-von-Siemens Centre for Industry and Science

Source: WvSC

Logo des EU European Regional Development Fund

Source: EU