Markus Schilling at the Full Notch Creep Test facility (FNCT)

Source: BAM

Project period

01/05/2019 - 30/04/2022

Project type

Interdisciplinary project

Project status

Closed

Description

The project aims at a systematic evaluation of the so-called “bottle-test” and the corresponding test liquids according to GGR 015 and DIN 2002 with respect to the damage mechanism environmental stress cracking (ESC).

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

Test specimen in the Full Notch Creep Test facility (FNCT) Source: BAM

Source: BAM

Source: BAM

Source: BAM

Partners

Bundesanstalt für Materialforschung und -prüfung (BAM)

Fraunhofer Institute for Structural Durability and System Reliability LBF

Section Plastics

Funding

Plastics Research Association (Forschungsgesellschaft Kunststoffe e.V., FGK)

AiF funded research project

(IGF project no. 20673 N), IGF project no. 20673 N

Small scale laboratory tests to assess the compatibility of packaging materials based on polyethylene against crop protection formulations

For plastic packaging and intermediate bulk containers (IBC) for transport of liquid dangerous goods made from polyethylene (PE-HD) a proof of sufficient chemical compatibility is required in the framework of a German or international approval. For crop protection formulations a small-scale laboratory test, the so-called bottle-test, has been developed in Germany as partial alternative to cost-intensive type testing of complete containers. This method, laboratory test E – determination of tensile-impact strength, has been established together with the corresponding test liquids in a national regulation GGR 015 which has just been transferred into a German standard DIN 2002. The applicability of this laboratory test and of the test liquids is currently limited as both are not yet introduced into standards and regulations outside Germany. Using systematic investigations of different PE-HD materials, the research project aims at increasing the acceptance of this laboratory test (bottle-test) on a national as well as international scale in order to establish the requirements for the transfer into further national and international standards and regulations.

Therefore, test results of the small-scale laboratory test according to GGR 015 and DIN 2002 will be evaluated in terms of the internationally accepted Full Notch Creep Test (FNCT). The FNCT addresses the environmental stress cracking (ESC) behavior of PE-HD using a special set-up also under influence of liquid media and allows to draw detailed conclusions concerning course and mechanism of damage. Now, evidence must be provided that results of the bottle-test are also mainly due to environmental stress cracking and therefore this test is adequate in the framework of approval procedures. A broad acceptance of the laboratory tests and the test liquids as well as the intended introduction into standards and regulations is expected to significantly facilitate the market access for manufacturers of crop protection products and containers, especially small and medium scale companies, in Europe and internationally.

The so-called bottle-test

Besides absorption and permeation, the bottle-test addresses predominantly the resistance against environmental stress cracking (ESC). For this purpose, test liquids have been developed in Germany which consist of various emulgators, surfactants and in part organic solvents and are considered representative for crop protection formulations with respect to their damaging effect in terms of ESC.

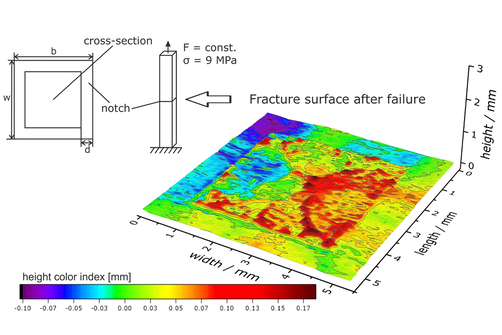

The Full Notch Creep Test

The Full Notch Creep Test represents a scientifically well-founded and also practically accepted methodological basis for the investigation of environmental stress cracking in polyethylene. It is based on the complete immersion of a circumferentially notched specimen in a temperature-controlled liquid test medium. After applying a constant force (well below the yield stress of the material) the time to complete failure of the specimen (fracture) is measured. Especially in combination with a fracture surface analysis, further details with respect to course and mechanism of the damage as well as to crack propagation are accessible.

Height profile (Laser Scanning Microscopy, LSM) of a characteristic fracture surface of a FNCT test specimen

Source: BAM, Division Mechanics of Polymers

Funding

The project "Labormethode zum Nachweis der chemischen Verträglichkeit von Behälterwerkstoffen aus Polyethylen gegenüber Pflanzenschutzformulierungen" is an AiF funded research project (IGF project no. 20673 N).

Source: AiF Forschungsnetzwerk Mittelsstand, Federal Ministry for Economic Affairs and Climate Action (BMWi), Plastics Research Association (Forschungsgesellschaft Kunststoffe e.V., FGK)