Sequence from a high-speed recording: Spark formation due to mechanical impact of a steel firing pin on a steel plate in an explosive gas mixture of hydrogen and air

Source: BAM

Project period

01/04/2021 - 15/10/2022

Project type

Collaborative research project

Project status

Closed

Description

In the HySpark project, the effectiveness of mechanical impacts as ignition source for explosive atmospheres containing hydrogen is being investigated experimentally, considering different material combinations.

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

Source: BAM

Impact sparks or hot friction surfaces, which are caused by mechanical impacts, are possible ignition sources in potentially explosive atmospheres. They can occur when using tools, machines and vehicles. The use of low-spark tools is therefore a possible measure for explosion protection. In the project, the effectiveness of this measure for gas mixtures containing hydrogen is investigated experimentally.

Source: BAM

Within the framework of the project, the influence of the material pairing on the ignition effectiveness of mechanical impacts in hydrogen containing atmospheres is investigated systematically. Furthermore, it is investigated experimentally how the addition of hydrogen to natural gas influences the effectiveness of mechanical impacts as ignition source. The results of the investigations are used, if necessary, for the revision of corresponding regulations.

Source: BAM

Due to mechanical impacts, separated particles of increased temperature or hot friction surfaces can be sources of ignition. The ignition probability depends, among other things, on the material pairing, the impact energy and the fuel gas. For the systematic investigation of the ignition effectiveness of these impact processes, an experimental set-up for impact experiments is used allowing the variation of these influencing factors in a targeted manner. The impacts take place in a closed enclosure that can be filled with defined gas mixtures.

Source: BAM

The HySpark project is a research cooperation between the Bundesanstalt für Materialforschung und -prüfung (BAM) and the Berufsgenossenschaft Rohstoff und chemische Industrie (Employer's Liability Insurance Association for Raw Materials and the Chemical Industry, BGRCI).

HySpark - Ignition of hydrogen-containing atmospheres by mechanically generated sparks

Motivation and background

With the widespread introduction of hydrogen technologies in the chemical and energy industries, hazards due to explosive atmospheres must be assessed more and more frequently and, if necessary, appropriate protective measures must be taken. The effect of mixing hydrogen into existing natural gas networks on the effectiveness of explosion protection measures must also be considered.

For maintenance and servicing work, e.g. on pressure control systems for the natural gas network, sections are often shut off, relieved and then opened. Purging the section with nitrogen before opening is usually only possible at great expense and is usually not carried out. Therefore, explosive mixtures cannot be safely excluded in defined areas. Within these explosion zones, ignition sources must be excluded at all costs during maintenance work.

The avoidance of ignition sources is one of the three basic measures for explosion protection. This measure is implemented primarily through the use of special, explosion-protected equipment, the design of which excludes the effectiveness of the equipment as a source of ignition. Non-electrical equipment must also be taken into account. Mechanically generated sparks or hot friction surfaces resulting from mechanical impacts caused by the use of tools or machines can be a source of ignition. The use of low-sparking tools in potentially explosive atmospheres prevents ignition during intentional or unintentional impact processes.

Whether ignition of explosive gas mixtures can be caused by mechanical impact depends on many parameters. In addition to the materials involved in the impact, the ignition sensitivity of the fuel gases is particularly decisive. The assessment of the ignition sensitivity of fuel gases by mechanical impact processes is usually only carried out on the basis of the minimum ignition energy of the fuel gases. Accordingly, natural gas is assigned to explosion group IIA as a less ignition-sensitive gas. Hydrogen is very sensitive to ignition compared with many other fuel gases and is assigned to explosion group IIC in accordance with the low minimum ignition energy. However, it is known from earlier studies that the ignition effectiveness of mechanical impact can be different for the IIC reference gases hydrogen and acetylene (see BAM Research Reports 292 and Vh2104) and that in the case of hydrogen, ignition due to mechanical impact occurs mainly at the hot friction surface caused by the impact. In previous investigations on the ignition effectiveness of mechanical impacts, almost exclusively homogeneous material pairings were investigated.

Aims and work packages

The aim of this project is, on the one hand, to investigate experimentally and systematically the effectiveness of mechanical impact as an ignition source in hydrogen/air mixtures allowing to assess the conditions that require the use of low-spark tools in potentially explosive atmospheres containing hydrogen as an effective and necessary explosion protection measure. In contrast to earlier studies, heterogeneous material pairings are used for impacts. Both low-alloy steels and stainless steels as well as non-ferrous metals used for low-spark tools are considered as impact partners. Furthermore, concrete is also considered as a typical floor covering. Based on the results, it will be assessed whether an adaptation of existing regulations for the use of low-spark tools is necessary.

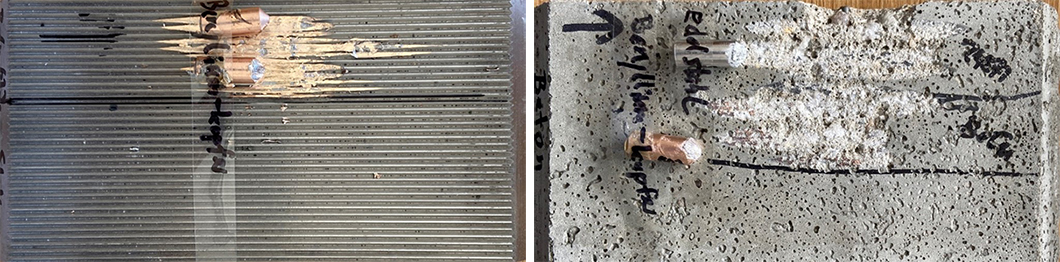

Test specimens after several impact test. Left: Impact plate made of steel (St50) with firing pin made of beryllium copper. Right: Impact plate made of screed concrete with impact pin made of beryllium copper

Source: BAM

In another work package, it will be investigated how the effectiveness of mechanical impact as an ignition source changes when hydrogen is added to the natural gas. Based on the experimental results, it will be assessed whether secondary explosion protection measures in connection with non-electrical equipment need to be adapted for an admixture of up to 25% hydrogen to natural gas, or at what proportion an adaptation becomes necessary.

Coordination

Bundesanstalt für Materialforschung und -prüfung (BAM)

Explosion Protection Gases and Dusts division

Project partners

BAM Bundesanstalt für Materialforschung und -prüfung (BAM)

Explosion Protection Gases and Dusts division

BGRCI - Berufsgenossenschaft Rohstoff und chemische Industrie

Funding

The HySpark project is a research cooperation between the Bundesanstalt für Materialforschung und -prüfung (BAM) and the Berufsgenossenschaft Rohstoff und chemische Industrie (Employer's Liability Insurance Association for Raw Materials and the Chemical Industry, BGRCI).