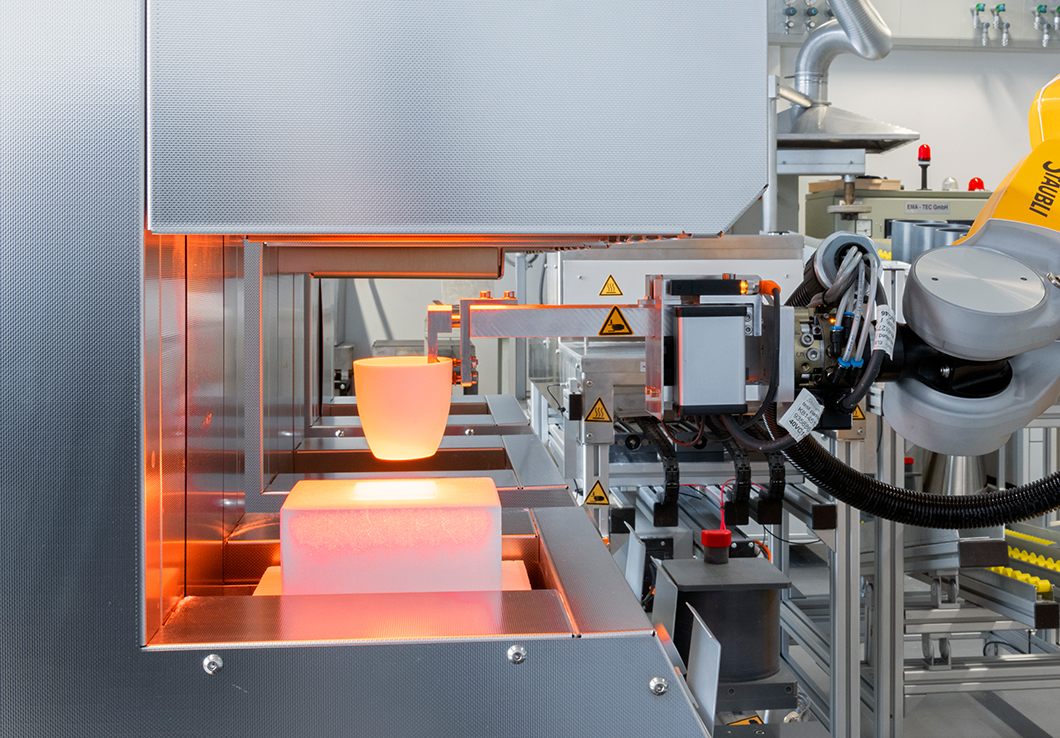

The robotic high-throughput glass melting system at BAM provides a starting point for the intended development of an ontology based digital infrastructure for high throughput glass design.

Source: BAM, Glasses division

Project period

01/02/2021 - 31/01/2024

Project type

Collaborative research project

Project status

Closed

Description

In the GlasDigital project - Data-driven workflow for accelerated glass development - digital tools for the high-throughput development of novel glass materials are to be developed.

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Unter den Eichen 87

12205 Berlin

Glass capillaries Source: BAM

Source: BAM

Source: BAM

Source: BAM

Partners

Bundesanstalt für Materialforschung und -prüfung (BAM)

TU Clausthal

Friedrich-Schiller-Universität Jena

Fraunhofer Institut für Silicatforschung Würzburg

Funding

The project is funded by the Federal Ministry of Education and Research (BMBF) as part of the Initiative for the Digitisation of Materials Research in Germany (MaterialDigital).

GlasDigital - Data-driven workflow for accelerated glass development

GlasDigital wants to elaborate digital tools for the high throughput development of novel glasses. Due to the low degree of automation, current glass development cycles are usually very cost, energy and time expensive. Particular challenges arise from the wide variability of possible chemical compositions, high process temperatures and the lack of process and glass composition-structure-property data. Robotic glass melting systems with self-learning machines and their integration into an ontology based digital infrastructure should overcome these problems.

Methodology and BAM's contribution

The development relies on a robotic glass melting system, for which a prototype was developed at Fraunhofer ISC, and exemplarily starts from a technically improved system at BAM. For this purpose, the system has to be equipped with inline sensors for process monitoring, machine learning (ML)-based, adaptive algorithms for melt monitoring and optimization, novel tools for HD glass analysis and ML-based, adaptive algorithms for glass design, including adaptive software tools for data mining. The enhanced front-end tool and the coupled system control software will be expanded in this regard and linked to the platform MaterialDigital (PMD).

Partners

Bundesanstalt für Materialforschung und -prüfung (BAM)

TU Clausthal

Friedrich-Schiller-Universität Jena

Fraunhofer Institut für Silicatforschung Würzburg

Funding

The project is funded by the Federal Ministry of Education and Research BMBF as part of the Initiative for the Digitization of Materials Research in Germany MaterialDigital

Source: MaterialDigital und BMBF