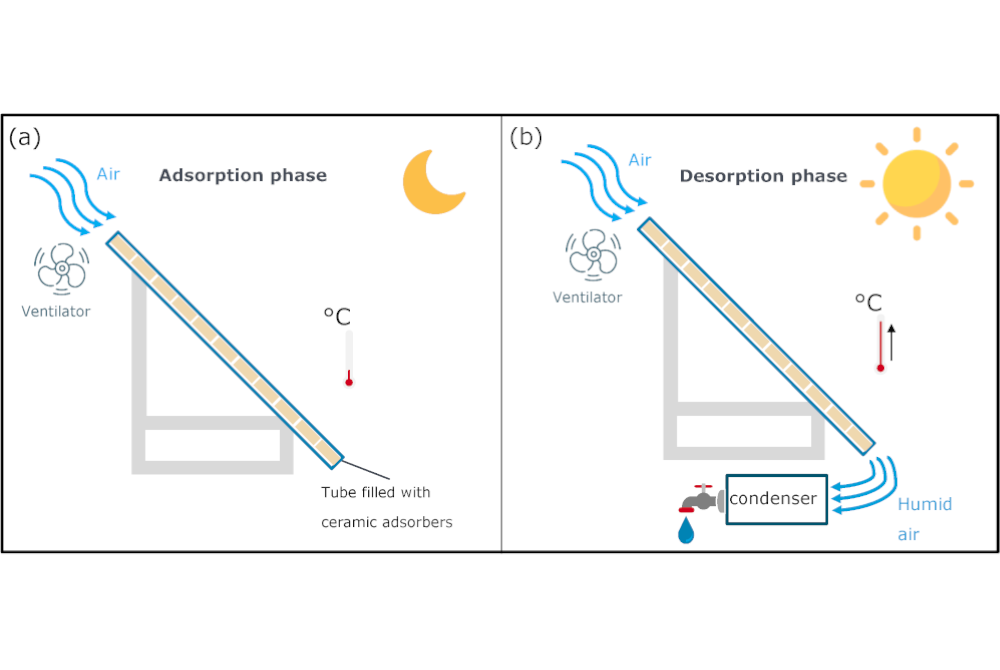

Process schematic and phases of the adsorption-driven atmospheric water harvesting: (a) During the night, adsorption phase; (b) During the day, desorption phase and water collection in the condenser

Source: BAM

Project period

01/11/2023 - 31/10/2025

Project type

Collaborative research project

Project status

Ongoing

Description

In the AdsoWaL project, solar collectors are developed which use an adsorption and thermally driven desorption process to convert humidity from the air into drinking water. To optimize the air flow and the adsorption kinetics within the collector, ceramic adsorbent bodies will be shaped by additive manufacturing from the active adsorbent material.

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Branch Fabeckstraße

Unter den Eichen 44-46

12203 Berlin

Source: BAM

Source: BAM

Source: BAM

Source: BAM

Project partners: Adsorbus GmbH, Berlin

Funding: Zentrales Innovationsprogramm Mittelstand (ZIM), Bundesministerium für Wirtschaft und Klimaschutz (BMWK)

Access to clean drinking, utility, and process water is a growing problem worldwide. In most parts of the world, decentralized, environmentally friendly, and high-quality water services are virtually non-existent.

Specially developed solar collectors use a solar-thermal adsorption process to convert humidity in the air into usable water—even in areas with low humidity.

The goal of this development is to demonstrate a prototype of a new type of solar collector that supplies approximately 5 litres of drinking water per day, can be modularly expanded, and is adaptable to various climatic conditions.

The adsorption material is integrated into the collector so that solar heat can be transferred directly to the adsorbent. This direct utilisation of solar heat makes the system more efficient, simpler, and more durable. Optimizing the airflow and adsorption kinetics in the adsorber are important steps in achieving the collector’s efficiency goals.

At the same time, this type of water collection can also be used in hyper-arid to semi-arid climate zones where relative humidity is well below 50%. Two approaches to optimizing the air flow are being investigated: one involves loose fill through access structures, while the other uses parts created by directly 3D printing the active adsorption material.