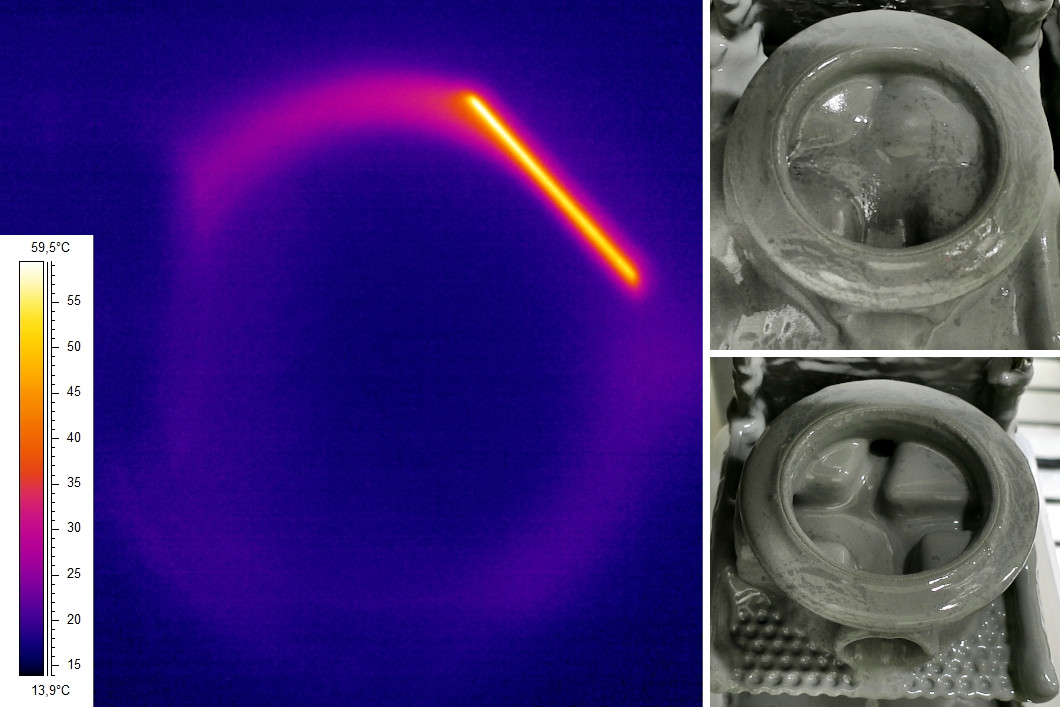

Left: thermal imaging during manufacturing; right: finished part being lifted from the suspension

Source: BAM, Technology of Construction Materials division and Ceramic Processing and Biomaterials division

Project period

10/05/2018 - 30/04/2020

Project type

Interdisciplinary project

Project status

Closed

Description

The AFChem project is concerned with the development of a laser-based process for the additive manufacturing of components with complex geometry from alkali-activated concretes with high chemical resistance.

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

AFChem - Additive manufacturing of components for highly chemically stressed infrastructure systems

Within the scope of the project, the "Laser-Induced Slip Casting" (LIS) process is applied to reactive suspensions such as alkali-activated binders and adapted or optimised for this purpose. Alkali-activated binders have a very high acid resistance when suitably formulated, which means that the resistance of components can be increased. The process was originally developed in cooperation with the Clausthal University of Technology for the additive manufacturing of ceramics.

The aim is to develop, optimise and scale up a process for the additive manufacturing of components based on alkali-activated binders. These are intended for use in chemically highly stressed areas, for example in wastewater structures with strong attack by biogenic sulphuric acid corrosion. At the end of the project, a laser-based process for the additive manufacturing of geometrically complex concrete components with high chemical resistance will be available for the first time.

This project adapts Laser-Induced Slip Casting (LIS), originally developed for processing ceramics, for alkali-activated binders, a cementitious material. In this process, a slurry is presented layer by layer and solidified using laser energy. This leads to a unique way of manufacturing building components, without the need for formwork construction. The aims of the project include developing an accessible building material for the laser-based additive manufacturing process and scaling the process to components with an edge length of up to 1.00 m. The components will be designed for use in chemical applications. The components will be suitable for use in chemically highly stressed areas, especially for wastewater structures with strong attack by biogenic sulphuric acid corrosion.