Manufacturing and performance of ceramic multilayer inductors

Source: BAM

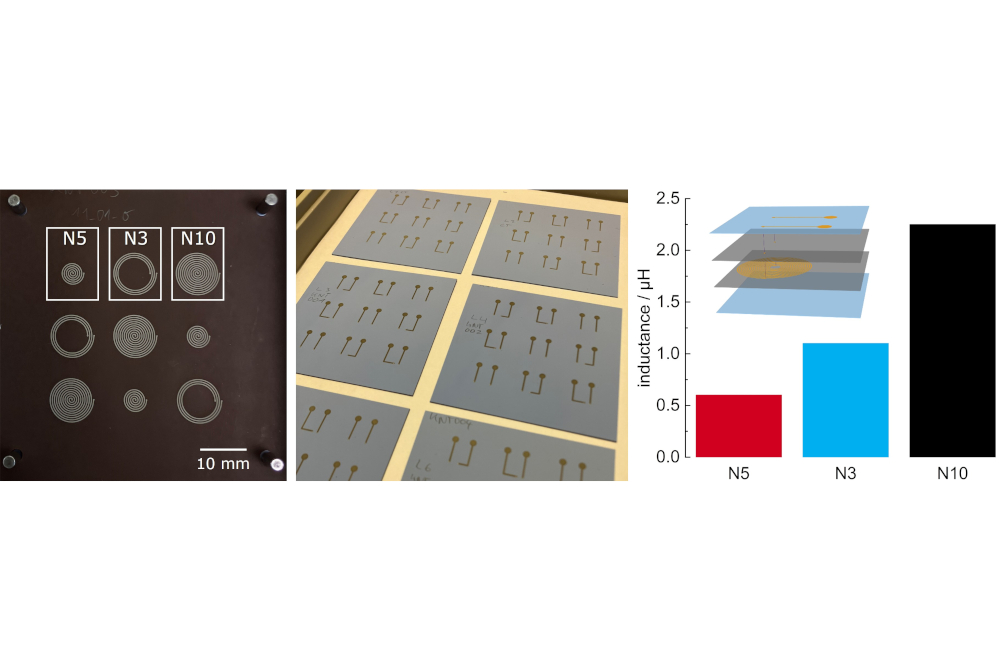

This study combines concepts for digitalization in materials science and engineering with a specific material and component development for integrated multilayer inductors. An important aspect in the development of miniaturized, integrated inductors in ceramic multilayer technology is the magnetic permeability of the magnetically active ferrite. In ceramic multilayer technology, microelectronic components, so-called ceramic multilayers, are created by combining individually structured and metallized tapes. The ceramic firing of all combined materials is done in one step as so-called co-firing. In this study, the effects of various processing steps of ceramic tape-casting and multilayer technology on the magnetic permeability of a NiCuZn ferrite are investigated and the production of an integrated multilayer inductor is demonstrated. Dry-pressed, tape-cast and co-fired ferrite samples are analyzed and their properties are correlated with the performance of the respective inductors. An automated data pipeline is implemented and used to semantically link the collected experimental data according to a domain ontology. The domain ontology is based on the core ontology of the Platform MaterialDigital. Example queries to the ontology show how the determined process-property correlations are accessible to non-experts and thus suitable material data for component design can be identified. It is shown how the inductance of co-fired multilayer inductors can be reliably predicted by finite element simulations if the material data is correctly selected according to the manufacturing technology used.

Impact of scan strategy on principal stresses in laser powder bed fusion

Björn Mieller, Sahar Ben Hassine, Jörg Töpfer, Christoph Priese, Arne Bochmann, Beate Capraro, Sebastian Stark, Uwe Partsch, Carina Fresemann

Advanced Engineering Materials, 2024