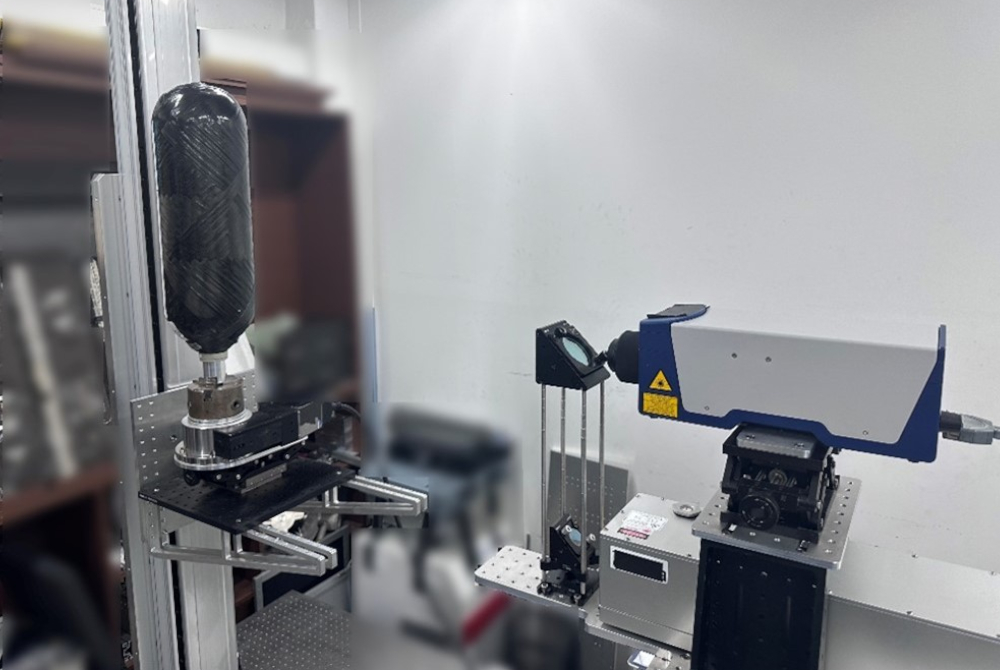

Composite pressure vessel during an investigation with pulse-echo ultrasonic propagation imaging

Source: BAM

Type IV pressure vessels, consisting of a polymer liner and a load-bearing composite structure, are increasingly being used in various applications due to their high potential for weight reduction, e.g., for the storage of gaseous hydrogen or breathing air. This type of composite pressure vessel is mostly manufactured using the so-called wet winding process, which is characterized by high complexity due to numerous process parameters and physical effects. Manufacturing-related effects lead to variations in the properties of the finished components and affect the safety level of the pressure vessels.

In a previous study, two designs of 6.8-liter composite pressure vessels were manufactured. The vessel geometry, the layup of the composite structure, and the materials used were identical in both designs. The only variable parameter was the pressure inside the polymer liner during winding: one design was wound with a constant internal pressure, and the other with an increasing internal pressure. The aim of internal pressure control was to achieve a more uniform residual stress state and to minimize possible fiber undulations. It was found that the design wound with increasing internal pressure exhibits a higher safety level. However, the potential to further increase the safety level was limited by failure in the cross-windings, which could not be explained by an analysis of the strain state.

The presented paper shows the results of an investigation of manufacturing-induced imperfections using the non-destructive pulse-echo ultrasonic propagation imaging. This method allowed for the rapid identification of imperfections that were responsible for the failure of the pressure vessels. The paper emphasizes both the potential of the pulse-echo ultrasonic propagation imaging for characterizing imperfections in safety-critical composite components and the necessity of a more in-depth analysis of the influence of manufacturing-induced imperfections on the safety of Type IV pressure vessels.

The investigations were carried out within the framework of the graduate program “Trustworthy Hydrogen” and the BMFTR funded project “Aufbau einer APRA-Forschungspräsenz für Sicherheitsforschung zur Wasserstoffsicherheit zwischen Deutschland und Südkorea“ at the Measurement Robotics & Diagnostic AI Lab of the Korea Advanced Institute of Science and Technology (KAIST). On the side of MAI Lab, the work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) [RS-2024-00397400].

Impact of internal pressure regulation in filament winding on the quality of composite cylinders: a study with pulse-echo ultrasonic propagation imaging

Bartosz Popiela, Kyunghwan Kim, Kyu-Jin Lee, Jung-Ryul Lee

Advanced Composite Materials, 2025