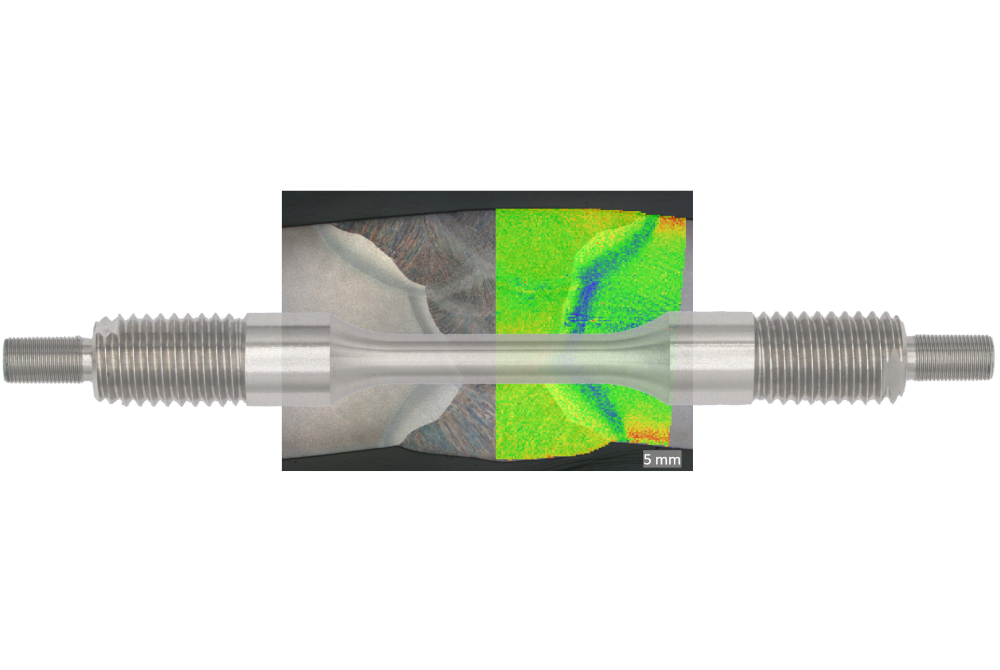

Metallographic cross-section of the weld seam with hardness measurement and extraction position of the cross-weld tensile specimen.

Source: BAM

The use of hydrogen as a sustainable energy carrier for a climate-neutral economy requires qualification of a large number of materials, as contact with gaseous hydrogen can influence the mechanical properties of components. The focus here is particularly on the materials that are already installed in existing natural gas networks, as these pipelines can offer an economically favourable path and rapid utilization, ensuring the distribution of the required amount of hydrogen gas.

This work shows the influence of gaseous hydrogen on welded joints. Welded joints have complex microstructural properties compared to the base metal, which can lead to different interactions when in contact with hydrogen. Such investigations allow therefore to identify possible weak points in components. For this purpose, tests are carried out using the innovative hollow tensile specimen. The hollow tensile specimens are characterized by the fact that they can be filled with hydrogen from the inside. This simplifies the analysis of the effect of hydrogen on the material properties when it is exposed to mechanical stress at the same time. To characterize the weld seam, the test specimens are manufactured as cross-weld tensile specimens, which contain both the weld seam and the unaffected base material. The results obtained are compared with the characteristic values for the base material.

The tests show a degradation of certain mechanical properties, specifically the ability to deform (i.e. ductility). This reduction is however unchanged for the samples with weld seam compared to the base material.

Investigation of resistance to gaseous hydrogen of a longitudinal weld seam in a X65 pipeline using the hollow specimen technique

Florian Konert, Jonathan Nietzke, Tomás Freitas, Michael Rhode, Oded Sobol, Thomas Böllinghaus

Welding in the World, Volume 69, pages 861–870, 2025