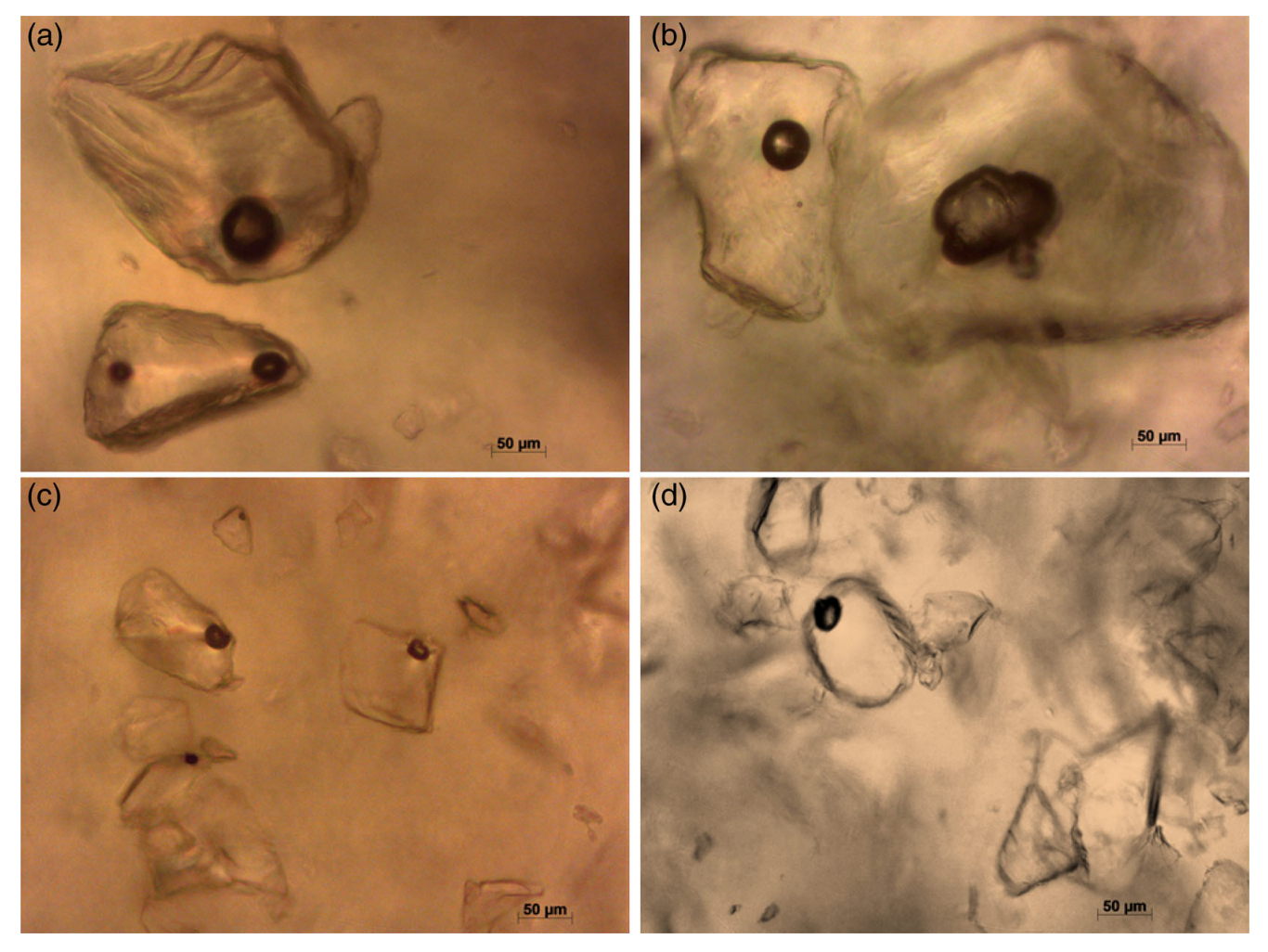

Thermal treatment can trigger a self-healing mechanism in damaged epoxy resin to which ethylene-co-methacrylic acid particles have been added. The gas bubbles (dark) that form at the interface between the particles and the epoxy matrix facilitate closing of the cracks by building up pressure during the heat treatment.

Source: BAM

Epoxy resins are high performance thermoset polymers and therefore commonly used as matrix for fiber-reinforced composites. Epoxies are among the most used thermosets resins, due to their superior physical-mechanical performances, high mechanical properties, high chemical resistance, low shrinkage on curing and high-use temperature. Their higher properties also make them widely used in structural applications as polymer matrices for fiber reinforced composites. Among their major disadvantages are brittleness, high flammability, and slow processing. Recent research has been developed to produce advanced epoxy matrices and overcome limitations related to processability, flammability, and fracture toughness. The modification of epoxy resin to produce a selfhealing material has also been studied over the last decades. Self-healing composite materials have been studied to overcome limitations related to conventional maintenance and repair methods. These materials have been developed to provide healing of microcracks in the composite structure with or without external intervention, extending service life and safety of the components and reducing maintenance time and cost. The addition of thermoplastics to thermosets to produce mendable polymers appears as a promising selfhealing technique. In this study, poly (ethylene-co-methacrylic acid) (EMAA) was added to epoxy resin and the effects of EMAA addition on epoxy properties were analyzed. Specimens with two different contents of thermoplastic and particles sizes were manufactured. A two-level full factorial experimental design was used to evaluate the effect of particle size and particle content on properties of epoxy modified with addition of EMAA.

Thus, lower EMAA concentration with smaller particle sizes may be optimal condition, considering the maintenance of base tensile properties of epoxy and homogeneity in particle distribution. A trade-off between healing efficiency and the reduction of mechanical properties must be considered and adjusted by the selection of particle concentration and particle size of the healing agent. In summary, results of this work may be applied for modification of epoxy and epoxy matrices for fiber reinforced composites with EMAA additive, with selection of particle size and concentration, as the studied parameters, for self-healing purposes.Epoxy resins are high performance thermoset polymers and therefore commonly used as matrix for fiber-reinforced composites. Epoxies are among the most used thermosets resins, due to their superior physical-mechanical performances, high mechanical properties, high chemical resistance, low shrinkage on curing and high-use temperature. Their higher properties also make them widely used in structural applications as polymer matrices for fiber reinforced composites. Among their major disadvantages are brittleness, high flammability, and slow processing. Recent research has been developed to produce advanced epoxy matrices and overcome limitations related to processability, flammability, and fracture toughness. The modification of epoxy resin to produce a selfhealing material has also been studied over the last decades. Self-healing composite materials have been studied to overcome limitations related to conventional maintenance and repair methods. These materials have been developed to provide healing of microcracks in the composite structure with or without external intervention, extending service life and safety of the components and reducing maintenance time and cost.

The addition of thermoplastics to thermosets to produce mendable polymers appears as a promising selfhealing technique. In this study, poly (ethylene-co-methacrylic acid) (EMAA) was added to epoxy resin and the effects of EMAA addition on epoxy properties were analyzed. Specimens with two different contents of thermoplastic and particles sizes were manufactured. A two-level full factorial experimental design was used to evaluate the effect of particle size and particle content on properties of epoxy modified with addition of EMAA. Thus, lower EMAA concentration with smaller particle sizes may be optimal condition, considering the maintenance of base tensile properties of epoxy and homogeneity in particle distribution. A trade-off between healing efficiency and the reduction of mechanical properties must be considered and adjusted by the selection of particle concentration and particle size of the healing agent. In summary, results of this work may be applied for modification of epoxy and epoxy matrices for fiber reinforced composites with EMAA additive, with selection of particle size and concentration, as the studied parameters, for self-healing purposes.

Effects of particle size and particle concentration of poly (ethylene-co-methacrylic acid) on properties of epoxy resin

Allana Nascimento, Volker Trappe, Lina Pavasaryte, José Melo, Ana Paula Cysne Barbosa

Journal of Applied Polymer Science, Volume141, Issue29, August 5, 2024