Contaminant Transport and Environmental Technologies

Source: BAM

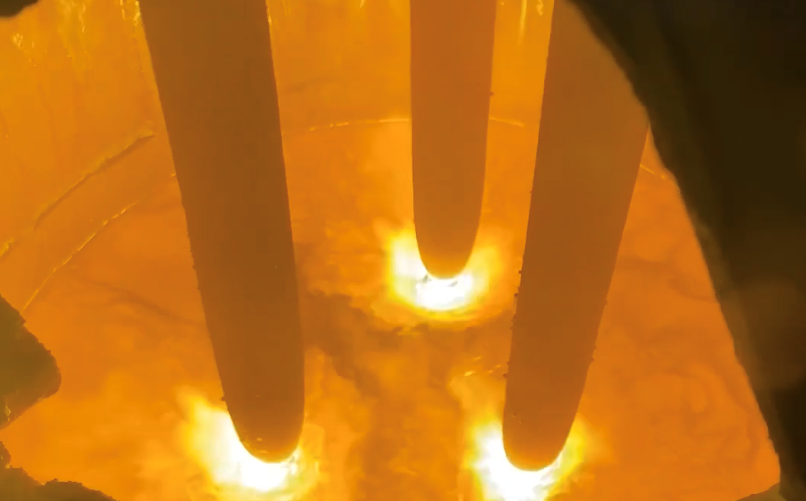

Red mud is produced as waste during the refining of bauxite into aluminum oxide, the starting material for aluminum production, in the so-called Bayer process. With an annual production of around 180 million tons, approximately 4 billion tons of this waste have already accumulated globally. As red mud consists of about half iron oxide and contains other valuable raw materials such as titanium and scandium, it is also a source of raw materials that should be recovered in the future. Here we show how red mud can be converted into a valuable and sustainable feedstock to produce 693 million tons of green steel using hydrogen plasma-based reduction without fossil fuels, which would mean a reduction of steel-related CO2 emissions by 1.39 billion tons. The process involves rapid reduction in the liquid state and viscous separation between iron and oxide slag. We explain the underlying chemical reactions and phase transformations during this simple and fast reduction method. Reduction by means of hydrogen plasma in the melt represents a sustainable approach for the recycling of waste from aluminum production while avoiding greenhouse gases in steel production.

Green steel from red mud through climate-neutral hydrogen plasma reduction.

Jovičević-Klug, M., Souza Filho, I.R., Springer, H. et al.

Nature 625, 703–709 (2024).