Aging of elastomers in air and in hydrogen environment: A comparative study

Source: BAM

Elastomer seals are used in containers for interim storage and final disposal of radioactive materials for operating times of several decades. Aging behavior and lifetime prediction of these components is a relevant research topic. This resulted in extensive knowledge about the aging processes of different elastomer materials and how the lifetime of O-ring seals can be predicted. Due to the expertise in the field of elastomer aging, a project was initiated in the course of the hydrogen initiative at BAM with the available resources. Within this project, different elastomer materials were aged in hydrogen and the results were compared with the existing data of samples aged in air. The results can help to assess which elastomer materials are suitable for a hydrogen infrastructure and to what extent existing gas pipelines can be operated with hydrogen as possible future energy carrier.

Samples made of three different elastomer materials were investigated: Ethylene-Propylene-Diene rubber (EPDM), hydrogenated Acrylonitrile-Butadiene rubber (HNBR) and fluorocarbon rubber (FKM). Different sample geometries were used for different measurement methods: O-ring segments with 10 mm cord diameter for compression set measurements, 2 mm thick flat samples for density and hardness measurements as well as tensile tests, and permeation samples with a thickness of 0,3 mm. Using a self-designed sample holder, the samples were put in an autoclave and aged for about 10, 30 and 100 days at 150 °C at 50 bar hydrogen pressure. The thermo-oxidatively aged samples were aged at ambient pressure (about 1 bar) at 150 °C in air-circulating ovens.

While hardness, density and tensile properties of EPDM and HNBR changed notably under air aging, only slight effects were observed for aging in hydrogen. This was expected, because oxygen as the main driver of degradation was not present in the hydrogen atmosphere. FKM, which is a very stable material also under air and ages only slowly, showed comparable aging effects under air and hydrogen. However, the tensile properties indicated a stronger stiffening of the material under hydrogen aging. Additionally, FKM exhibits the lowest hydrogen permeability of three investigated materials, which means that the hydrogen gas can only diffuse very slowly through the material. On the other hand, EPDM exhibits a significantly higher permeability than the other two materials. This is unfavorable for the application in gas pipelines, as it leads to higher leakage/gas loss.

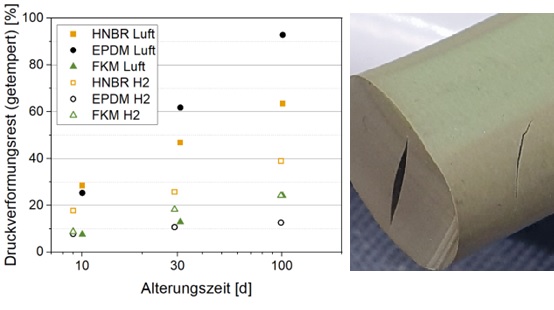

Furthermore, compression set (CS) measurements were performed, where the recovery of samples aged in compression is measured after release from compression. Again, EPDM and HNBR exhibited significantly smaller aging effects under hydrogen than the samples aged in air. EPDM even exhibited the lowest CS values of all three materials (see figure). Again, the values of FKM were similar for both aging media, which suggests that oxygen does not play a significant role for FKM degradation also for aging in air. Additionally, the FKM O-ring segments aged in the compressed state for 100 days under hydrogen exhibited cracks (see figure). Due to the low permeability of the FKM material, the hydrogen stored at elevated pressure (50 bar) in the material could not escape quickly enough when the pressure was lowered and led to bubble formation in the material (“rapid gas decompression”). That the samples aged for 100 days were subjected to several pressurization and depressurization cycles probably promoted the development of cracks. As the cracks only appeared in the sample that was aged under compression, both the additional stresses from compression as well as the lower free surface for degassing due to the compression plates could contribute to crack formation.

In summary, EPDM exhibited the best aging stability under hydrogen, but also the highest gas permeability. HNBR showed the highest aging effects of the three materials both under air and hydrogen. FKM exhibited similar aging effects under air and hydrogen, but a stronger stiffening in the tensile tests after hydrogen aging. Additionally, the compressed FKM O-ring segment aged for 100 days at 150 °C in hydrogen developed cracks.

Aging of elging of elastomers in air and in hydrogen environment: A comparative study

M. Zaghdoudi, Anja Kömmling, Martin Böhning, Matthias Jaunich

International Journal of Hydrogen Energy, Volume 63, 18 April 2024, Pages 207-216