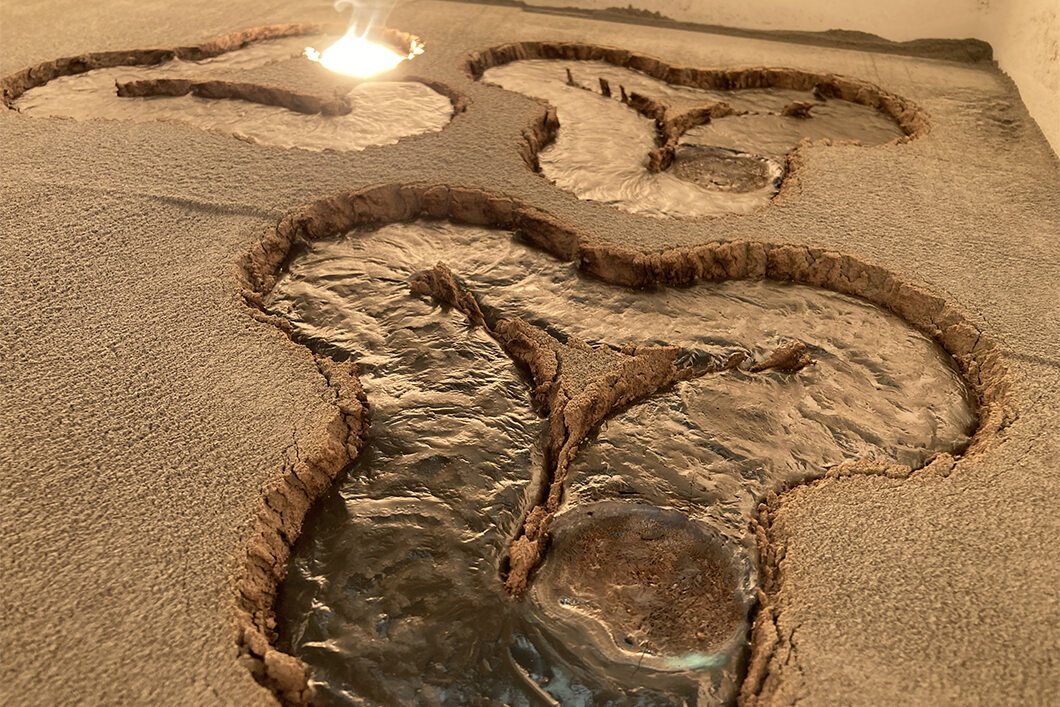

Tile made from lunar dust simulant by laser melting in a 50 mm laser spot.

Source: BAM

To advance space exploration towards long-term missions, it will be crucial to use in-space manufacturing (ISM) and in-situ resource utilization (ISRU) technologies. Given the extreme costs of shipping materials from Earth, a prerequisite for future human exploration will be the fabrication of objects directly on the surface of the Moon. Raw materials and energy can be harvested directly from the lunar surface, leaving equipment and some consumables the only necessity that must be brought from Earth. The technology proposed in this paper, the laser melting of a lunar regolith simulant (representing the energy of the sun and the lunar dust respectively) acts in place of existing resources for manufacturing on the Moon. The generation of suspended dust when moving a vehicle across the lunar surface is a major risk for lunar exploration. When lunar dust is in contact with the exploration equipment, it can lead to different damages on the instruments. Therefore, one of the first steps towards establishing a lunar base is the creation of infrastructure elements, such as roads for rovers and landing pads, as these constructions can help with dust mitigation. The main objective of the work presented in this paper is to produce elements with molten regolith that could be used during human and robotic lunar explorations to pave large areas and help to solve dust attenuation problems on the lunar surface. This technology is envisioned to play a major role in the first phase (survivability) of lunar infrastructure and base development, and over time to contribute to all phases of lunar exploration: robotic lunar exploration, survival, sustainability, and operational phase.

Laser melting manufacturing of large elements of lunar regolith simulant for paving on the Moon

Juan Carlos Ginés-Palomares, Miranda Fateri, Eckhard Kalhöfer, Tim Schubert, Lena Meyer, Nico Kolsch, Monica Brandic Lipinska, Robert Davenport, Barbara Imhof, René Waclavicek, Matthias Sperl, Advenit Makaya, Jens Günster

publisched in nature scientific reports, volume: 13, essay number: 15598, pages 1 bis 10

BAM Materials Engineering

BAM Advanced Multi-materials Processing