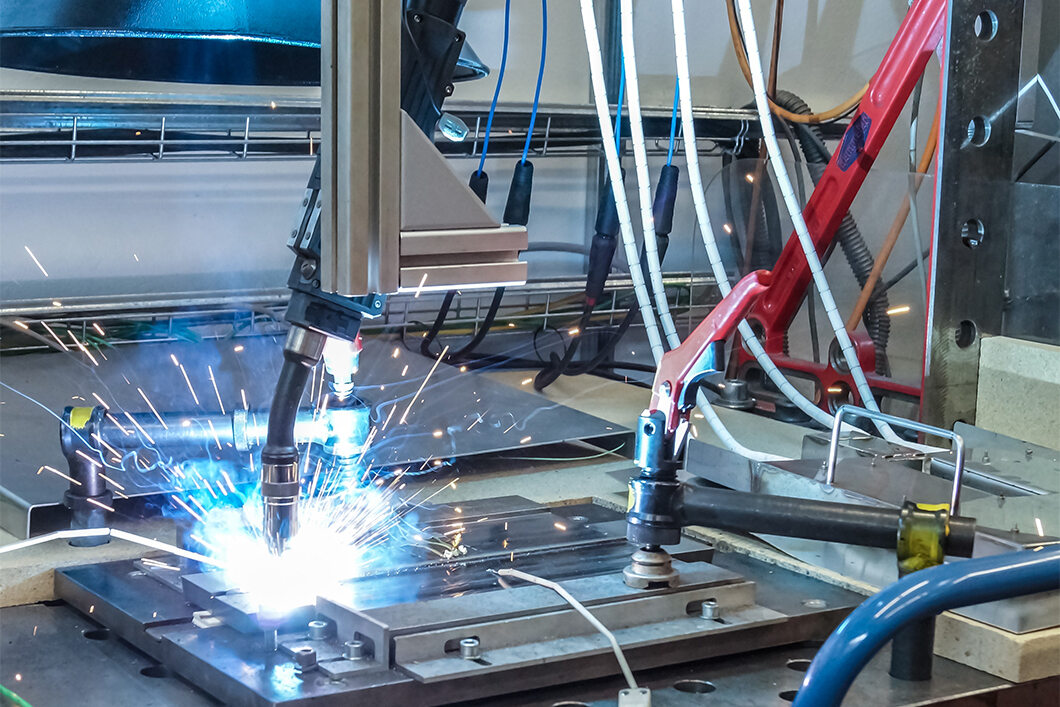

Automated metal active gas welding

Source: Michael Rhode, Thomas Kannengießer, BAM

For economic purposes and due to the desire for constructive lightweight construction, standardised, high-strength structural steel is increasingly being used in numerous branches of industry. However, standardisation only takes into consideration the mechanical properties and therefore allows the alloying elements to be varied within certain limits. This leads to steels of the same strength class being realised by means of different alloying concepts. Especially the number and the quantity of microalloying elements, such as titanium and niobium, can differ significantly. As a result, the properties of the heat-affected zone (HAZ) can vary greatly with the same welding process parameters. An undesirable property is the softening of certain areas of the HAZ. It is of safety and economic relevance whether there is a different load-bearing behaviour of these steels after further processing due to microstructural differences. This article provides valuable insights into the investigations carried out to date and shows the significant differences between various microalloying elements and their metallurgical effect on the formation of the HAZ of a high-strength fine-grained structural steel. Furthermore, thermodynamic predictions are made by means of special software (ThermoCalc), which shows the thermal stability and precipitation behaviour in critical areas of the HAZ, where softening or hardening occurs with respect to the base material. For example, the high-strength FKB, which was exclusively micro-alloyed with titanium, showed intensive softening of the outer HAZ areas. Whereas the niobium microalloyed steel showed resistance to severe softening. The explanation lies in the divergent metallurgical behaviour during welding of these steels.

Doctoral candidate Nina Schröder in a welding laboratory. Source: Nina Schröder, BAM

Thermodynamic prediction of precipitations behaviour in HAZ of a gas metal arc welded S690QL with varying Ti and Nb content

Nina Schröder, Michael Rhode, Thomas Kannengießer

published in Welding in the World, The International Journal of Materials Joining, Seiten 1-10

BAM Component Safety and Weld Mechanics