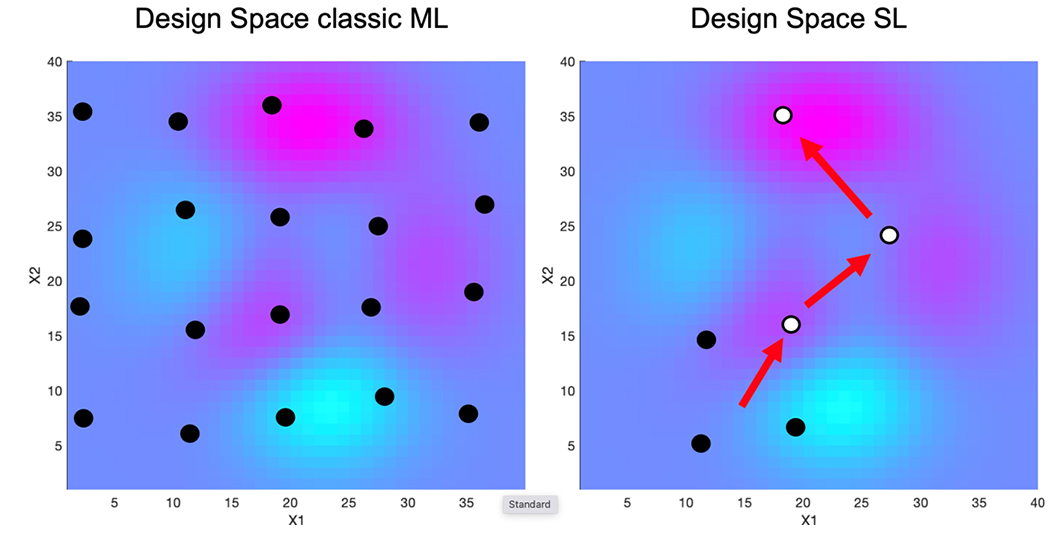

Design space classic ML | Design space SL

Source: BAM

The production of building materials has been particularly energy-intensive to date, and alternative, climate-friendly materials are difficult to produce. The paper presented describes how the use of artificial intelligence (AI) could accelerate development.

The production of building materials is a significant contributor to carbon emissions worldwide. Cement production alone accounts for about eight percent of global emissions of the greenhouse gas.

Alternative and more environmentally friendly cements replace the energy-intensive manufacturing processes in the kiln with self-running chemical reactions. Precursors and chemicals react without the addition of heat to produce materials that have nearly identical properties to cement, while emitting virtually no CO2.

However, it is difficult to gain an understanding of the properties of alternative cements and the conditions of their reaction. This is because cement is a very complex material. In particular, the constituents of the CO2-friendly cements can differ greatly depending on their geological origin and react differently accordingly.

In purely mathematical terms, this leads to billions of possible combinations. The traditional optimization of formulations on the basis of empirical observations in the laboratory reaches its limits here simply because of the quantity of possible combinations.

Artificial intelligence (AI) can help predict material properties. This is done by learning the empirically observed material properties from an AI model to predict new and potentially better products. However, even AI models still require large amounts of empirical data. For cement in particular, this "hunger for data" is a problem because data generation is tedious.

The use of Sequential Learning (SL) promises a breakthrough here. The crucial difference to previous AI: SL also searches for new end products beyond the already known and empirically tested materials and gets by with much less data. Research that does not lead to the goal is discarded early and promising experiments are preferred.

SL has been successfully applied, for instance, in the development of pharmaceuticals or metallic glasses - i.e., products whose synthesis is fast or which can be simulated well. For cements, years of development cycles would be required even with SL, since properties are typically determined after weeks of laboratory work.

In our work, we have now shown that it is possible to use SL for cement research as well. For this purpose, SL was adapted to the requirements in the laboratory and further accelerated by a novel approach. This means that we reliably succeeded in identifying suitable climate-friendly materials in less than eight months.

Sequential learning to accelerate discovery of alkali-activated binders

Christoph Völker, R. Firdous, Sabine Kruschwitz, D. Stephan

Published in Journal of Materials Science, Vol. 56, pages 15859-15881, 2021

BAM department Non-destructive Testing