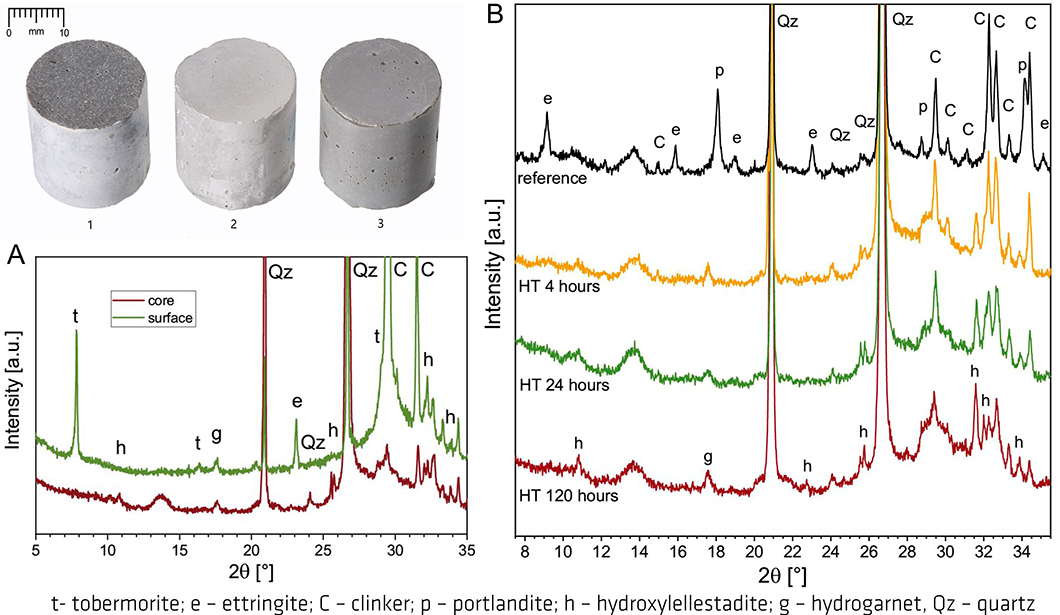

Samples: (1) polished, (2) after & (3) before hydrothermal treatment (HT) and X-ray analysis (A) comparison surface/core (B) duration of HT (BAM, 7.1)

Source: BAM, division Building Materials

The optimization of building materials can lead to savings of resources and energy. Several studies show that thermal and hydrothermal treatment can further improve the excellent properties of Ultra-High Performance Concrete (UHPC) in terms of mechanical strength and durability. Reason for the optimization are changes in the mineralogical phase composition of the artificial stone concrete. While for the thermal treatment the increase in strength is attributed to an intensified pozzolanic and hydraulic reaction, for the hydrothermal treatment previous studies accredited it mostly to the formation of tobermorite. In the presented study thermal and hydrothermal treatment of small sized UHPC samples was systematically varied and the phase formation analysed related to the strength development of a reference sample cured for 28 days in water. For the thermal treatment the results show that the strength increase depends on the availability of water and therefore on the protection against desiccation and can be ascribed to an improved pozzolanic reaction of the siliceous fillers. To achieve a significant enhancement of strength, a pre-storage time of few days and a long dwell time at elevated temperature/pressure are required. For the hydrothermal treatment already heating the specimens up to 185 °C in saturated steam followed by an immediate cooling leads to a substantial increase in compressive strength. Pre-storage time did not affect the result as far as a minimum of several hours is guaranteed. The improved performance is due to an increase in the pozzolanic and hydraulic reaction. The fact that even after a very long treatment time there are still unreacted clinker phases left, points to the fact that the reaction is again controlled by the availability of water. Surprisingly, tobermorite was only found within a very thin layer at the surface of the sample, but not in the bulk. Sulphate and aluminium stemming from the decomposition of the ettringite are bound in the newly formed phases hydroxylellestadite and hydrogarnet. In case a permanent integration can be verified in further studies, this would allow the wider use of sulphate bearing raw materials.

Thermal and hydrothermal treatment of UHPC: influence of the process parameters on the phase composition of ultra-high performance concrete

Julia von Werder, Sebastian Simon, André Gardei, P. Fontana, Birgit Meng

published in Materials and Structures, Vol. 54, Issue 1, Article 44, 2021

BAM division Building Materials and division Technology of Construction Materials