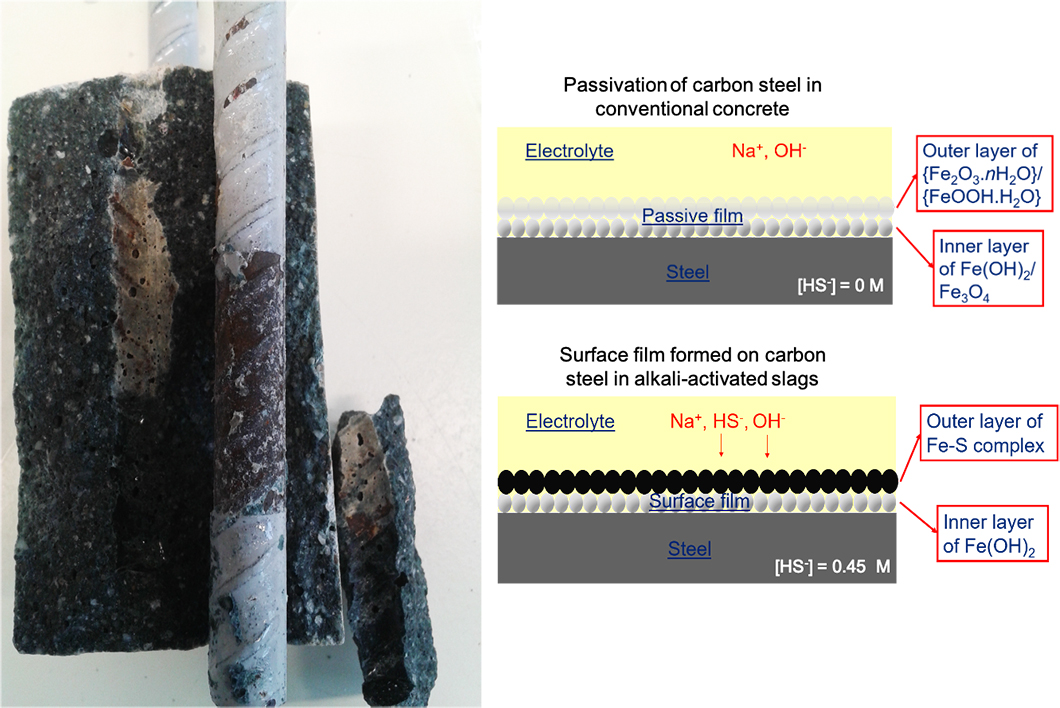

Left: Steel extracted from alkali-activated slag mortar. Right: Schematic showing the influence of sulfide on the surface of carbon steel.

Source: BAM, division Technology of Construction Materials

Alkali-activated slags (AAS) are formed from the reaction between an alkaline solution and ground granulated blast furnace slag (GGBS) and are a potential alternative to Portland cement (PC) in specific applications. Though the chemistry of AAS is relatively well known, its long-term durability when used in steel-reinforced concrete structures is not completely understood. One of the major differences in the chemistry of the pore fluid within PC and AAS is the presence of reduced sulfur (HS-) in the latter, that are known to influence steel passivation and chloride-induced corrosion behaviour. Given that steel corrosion is the major cause of premature degradation of reinforced concrete structures, it is imperative that we understand the corrosion behaviour of steel in concretes made from such binders.

This research, conducted mainly at The University of Sheffield and BAM, investigates the interaction between AAS and the steel reinforcement and its effects on the chloride-induced corrosion behaviour. The presence of HS- in the pore solution of AAS creates a highly reducing environment around the steel-concrete interface. In the highly alkaline pore solutions, competitive adsorption of OH- and HS- at the steel-solution interface inhibits and retards the formation of an oxide passive film on the steel, and instead favours the formation of an Fe-S complex. In addition, the absence of dissolved oxygen due to the presence of HS- at the steel-concrete interface does not allow the formation of a macro-cell and hinders chloride-induced corrosion. Moreover, because of the presence of additional redox couples involving sulfur in AAS, measurements of the open circuit potential and electrochemical measurements that rely on the application of an external potential cannot be applied to determine whether the steel is in the passive or actively corroding state as for sulfide-free cements.

These results have important implications for how we analyse the corrosion behaviour of steel in slag-containing binders and concretes. Among other things, the results show that one must carefully consider the presence of various anions when applying recommendations or standards applicable for PC and other conventional cements to AAS and modern binders with differing chemistries. These implications are explored in detail in a current DFG project at BAM.

Mechanisms of passivation and chloride-induced corrosion of mild steel in sulfide-containing alkaline solutions

Shishir Mundra, J. L. Provis

published in Journal of Materials Science, Vol. 56, issue 26, pages 14783 - 14802, 2021

BAM, division Technology of Construction Materials