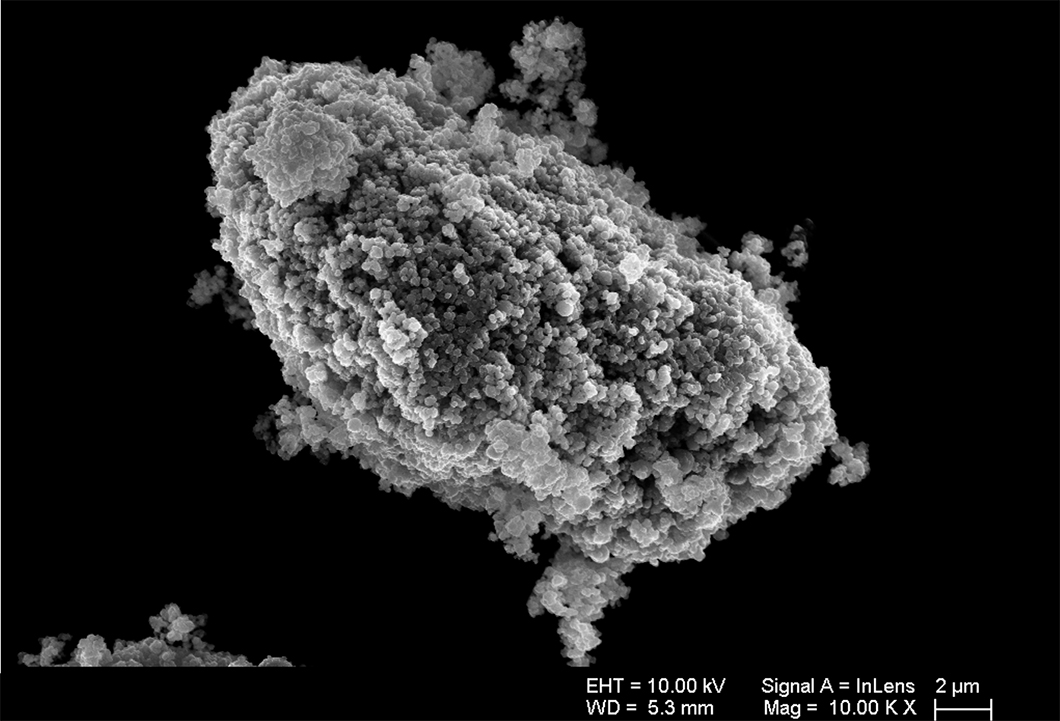

Scanning electron microscope image of an agglomerate of nanometre aluminium particle

Source: BAM

The severity of a dust explosion is determined by the so-called maximum explosion pressure and the maximum rate of pressure rise. These characteristics, which depend on the properties of the sample, are determined using precisely defined test apparatus and conditions, which are described in international standards. However, these were developed for dusts consisting of individual particles with diameters in the micrometre range (micrometre powders). Are the established standards also suitable for examining dusts whose primary particles have much smaller diameters in the nanometre range (so-called nano powders)?

Within the framework of a scientific collaboration with the University of Lorraine in Nancy and INERIS (Institut National de L'Environnement Industriel et des Risques) near Paris, investigations were carried out on various nano powders (aluminium, carbon black, nanocellulose) and the influence of sample preparation and handling on the explosion behaviour of the samples was researched. In this way, possible weaknesses and limitations of existing standard investigations were to be identified.

The focus of the comparison of different methods was on the dispersion of the dust particles (turbulence and homogeneity of the dust cloud). At concentrations that are necessary for a dust explosion to occur and take place, it is not possible to prevent the individual nanometre particles from sticking together. This results in so-called agglomerates, as can be seen in the picture (scanning electron microscope image of an agglomerate of nanometre aluminium particles). It became clear that the size of the agglomerates can be reduced again by injecting and dispersion. However, the explosion severity did not increase significantly compared to micrometre powders.

Furthermore, an influence of the experimental results by the very strong ignition sources (chemical/pyrotechnical igniters) prescribed for the standard tests is already known for micrometre powders. In the case of nano powders, this behaviour can be intensified due to their very high ignition sensitivity. Furthermore, unintentional pre ignition of very ignition sensitive nano powders before the ignition source is triggered has also been observed. As a result, measurements could not be evaluated, and the test equipment could be damaged.

Evaluating the explosion severity of nanopowders: International standards versus reality

A. Santandrea, A. Vignes, Arne Krietsch, D. Brunello, L. Perrin, A. Laurent, O. Dufaud

published in Process Safety and Environmental Protection, Vol. 138, pages 279 - 291, 2020

BAM, Division Explosion Protection Gases and Dusts