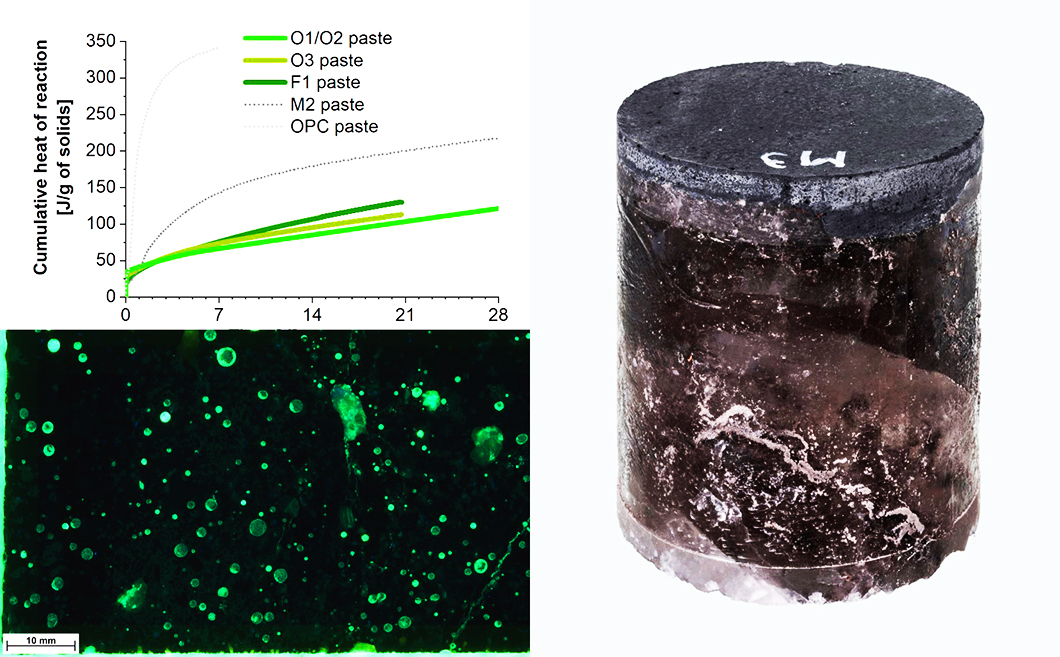

Cumulative heat of reaction, optical microscopy under UV-light and alkali-activated mortar on rock salt

Source: BAM, Technology of Construction Materials

Despite the decided exit, Germany is still one of the world’s biggest producers of nuclear energy. The reliable sealing of the radioactive waste is highly important not only for the current society but especially for the safety and the environment of future generations. In Germany, amongst others, especially rock salt formations are considered to be suitable as host rock for nuclear waste repositories, due to their low permeability. The entries of the actual repositories in the rock need to be closed and sealed. The main function of sealing structures is thus to ensure the integrity of the geological barrier. At early ages after construction, the heat of reaction of hardening cements and the cooling down after the ceasing of the reaction causes thermal stress. The compensation of the stress can lead to serious crack formation, which significantly lowers the barrier function of the sealing for the environment. To solve the existing problems the use of cements, which provide sufficient mechanical and physical properties, but provide considerably lower heats of reaction than the ones that are recently studied, is necessary.

Because of their excellent chemical durability, alkali-activated cements represent promising candidates for the application in sealing structures in rock salt. For this reason, BAM is developing alkali-activated mortars with rock salt aggregate. To evaluate their general suitability, various mortars were studied regarding the released heat during hardening, as well as fresh paste properties and properties of the mortars after hardening. The heat of reaction of the used alkali-activated cements was up to 55 % lower than that of a reference binder, which was originally designed for the application at the Morsleben site. The hardening is slower, and during the extended fresh state period tensions can still be compensated. However, an increasing ambient temperature– i.e. under conditions as expected for the desired application – the reactivity of the starting materials increases and thus the reaction kinetics are strongly accelerated. Other relevant properties depended strongly on the mix-design of the mortars and the curing conditions. In summary, the present results show that alkali-activated mortars can provide crucial benefits for the construction of sealing structures in evaporite rock.

Properties of alkali-activated mortars with salt aggregate for sealing structures in evaporite rock

P. Sturm, J. Moye, G.J.G. Gluth, N. Vogler, A. Taffe, H.-C. Kühne

published in Open Ceramics, Vol. 5, article No. 100041, 2021

BAM division Technology of Construction Materials