Laser excited super resolution thermography for nondestructive inspection of internal defects

Source: BAM, division Thermographic methods

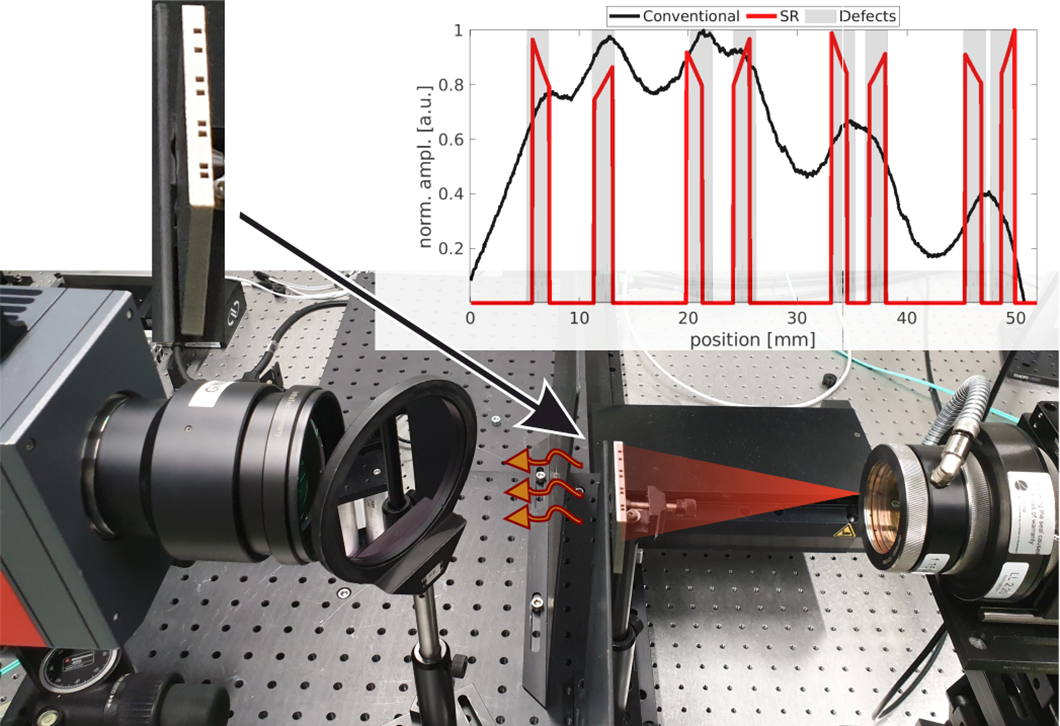

Active thermography already has a wide range of applications in nondestructive testing, especially in the examination of metals and fiber composites. Nevertheless, closely spaced defects and defects deep below the surface can only be detected poorly or not at all. This is mainly due to heat diffusion. It is not possible to simply send out a transmission pulse and measure the reflected propagation time, as in RADAR or ultrasound, because such a heat pulse immediately dissipates in all directions. A cooperation of BAM, TU Berlin and RECENDT (Linz) has now developed a method which can improve the usual spatial resolution limit of thermography significantly. Instead of a single heat pulse which heats the entire surface at once, the surface is now heated step by step and overlapping one after the other by using a laser line. The motivation for such a structured illumination comes from optical microscopy, where it is used for "super-resolution microscopy." Taken together, all of these measurements share a common characteristic: they all look at the same specimen with the same local defect distribution. Since defects are usually rare, the common property of the measurements is titled "joint sparsity". Mathematical optimization methods make it possible to solve the underlying inverse problem, i.e. the reconstruction of the defect position from the measured temperature distribution. For instance, closely spaced cavities in additively manufactured stainless steel components can be separated from each other with a spatial resolution more than four times better than the state of the art has allowed so far. The experimental requirements are comparatively low because, in combination with the mathematical approach, no precise local control of the laser illumination is required. If slightly less resolution enhancement is required, even a continuous scan within a few seconds is possible.

Laser excited super resolution thermal imaging for nondestructive inspection of internal defects

Samim Ahmadi, Julien Lecompagnon, Philipp Hirsch, P. Burgholzer, P. Jung, G. Caire, Mathias Ziegler

published in Scientific Reports, Vol. 10, Issue 1, page 22357, 2020

BAM division Thermographic Methods