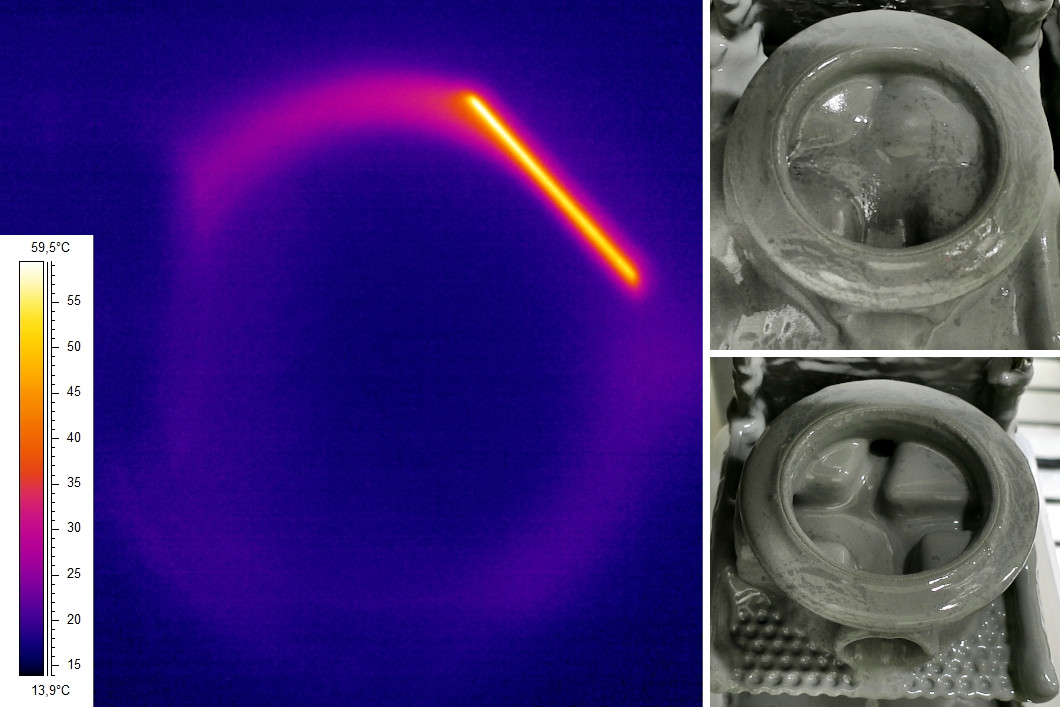

Left: thermal imaging during manufacturing; right: finished part being lifted from the suspension

Source: BAM, Technology of Construction Materials division and Ceramic Processing and Biomaterials division

Additive manufacturing is an established process to produce parts from polymeric materials and metals. It offers more versatility and enables production of elements that cannot be easily produced by other processes. During recent years, additive manufacturing of ceramics and construction materials, such as mortars and concretes, has received increasing attention in research and industry, as similar advantages as for polymers and metals can be expected. In addition, additive manufacturing of concrete elements can significantly decrease or even remove framework cost, which is normally in the range 35–60 % of the total construction cost and can be much higher for complex geometries.

In a collaborative effort of ceramicists and construction materials scientists at BAM, a previously designed process for additive manufacturing of ceramic parts, laser-induced slip casting (LIS), was adapted to the production of alkali-activated materials, an emerging class of binder materials with a range of promising applications in ceramic industry and construction industry. In the new process, a suspension with reactive particles is heated by laser radiation to produce solid layers of desired geometry, and the process is repeated layer by layer until the part is finished. Heating the suspension accelerates the hardening reactions in the affected volumes. By these means and subsequent additional curing, parts with compressive strengths of up to ~50 MPa and flexural strengths of up to ~12 MPa were produced, higher than what has been reported for alkali-activated materials produced by additive manufacturing previously. Additional advantages of the new process include high building rates, high accuracy and the possibility for upscaling to produce parts with dimensions of the order of metres.

A Novel Approach to Additive Manufacturing of Alkali-activated Materials: Laser-induced Slip Casting (LIS) of Lithium Aluminate/Silica Slurries

Petr Hlaváček, Gregor J.G. Gluth, Jörg Lüchtenborg, Patrick Sturm, Thomas Mühler, Hans-Carsten Kühne, Jens Günster

published in CMT Ceramics in Modern Technologies, Volume 1, Issue No 2, 2019

BAM, Technology of Construction Materials division and Ceramic Processing and Biomaterials division