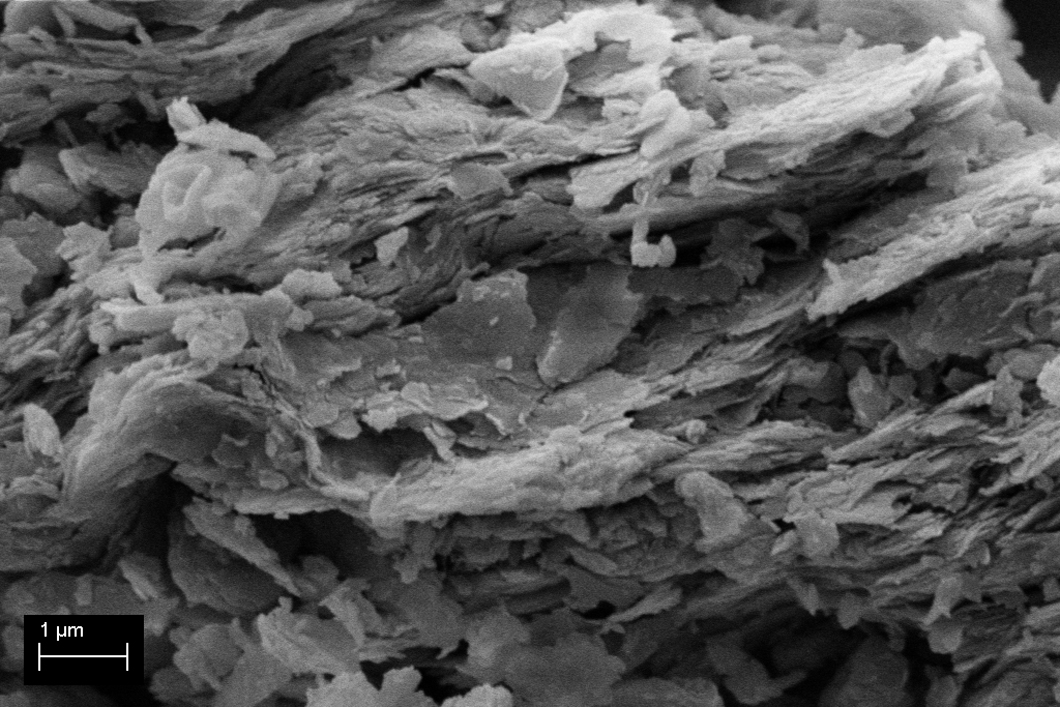

Micrograph of a calcined brick clay with typical aggregates of platy (dehydroxylated) clay particles.

Source: BAM, Technology of Construction Materials division

Concrete, with a yearly production volume of about 6 billion m³, is the most important human-made material. The production of concrete is tied to the use of cement, the manufacture of which causes 5–10 % of worldwide anthropogenic CO2 emissions. Therefore, it is a declared goal of German policy and the German cement industry to significantly lower the CO2 emissions related to cement production.

At present, the most technological-economical feasible approach to attain this goal is to decrease the proportion of clinker in cements (“clinker factor”) by substitution of clinker with other reactive compounds. Currently, these are mainly secondary raw materials from energy production and metallurgy. However, due to changes of production locations and processes, the available volume of these materials is continuously decreasing and will reach a level too low to be viable for cement production in the foreseeable future. In the search for alternative materials, calcined clays have become an important focus. Calcined kaolinitic clays (metakaolin), which are highly reactive, received the most attention in this regard. Suitable kaolinitic clays, however, are available only in limited amounts, and they are economically not viable for the cement industry.

For these reasons, different brick clays, the use of which for brick production has considerably decreased in Germany, have been investigated and compared with more kaolinite-rich clays regarding their use as cement component (supplementary cementitious material). The study at BAM has shown that brick clays with suitable composition, calcined at optimum conditions, have a performance that is very similar to that of the kaolinitic clays. It was found that the iron content of the clays is an important compositional parameter, mainly because iron acts as a flux and, thus, can lead to a significant decrease of the specific surface area via agglomeration or sintering of the clays during calcination. In addition, a reliable and simple method to determine the extent of calcination/dehydroxylation of illite, the major clay mineral in the brick clays, was proposed. This method can be a suitable measure to monitor the conditions during clay calcination on an industrial scale.

Comparison of calcined illitic clays (brick clays) and low-grade kaolinitic clays as supplementary cementitious materials

Nsesheye S. Msinjili, Gregor J. G. Gluth, Nico Vogler, Hans-Carsten Kühne

BAM, Department Safety of Structures, Division Technology of Construction Materials