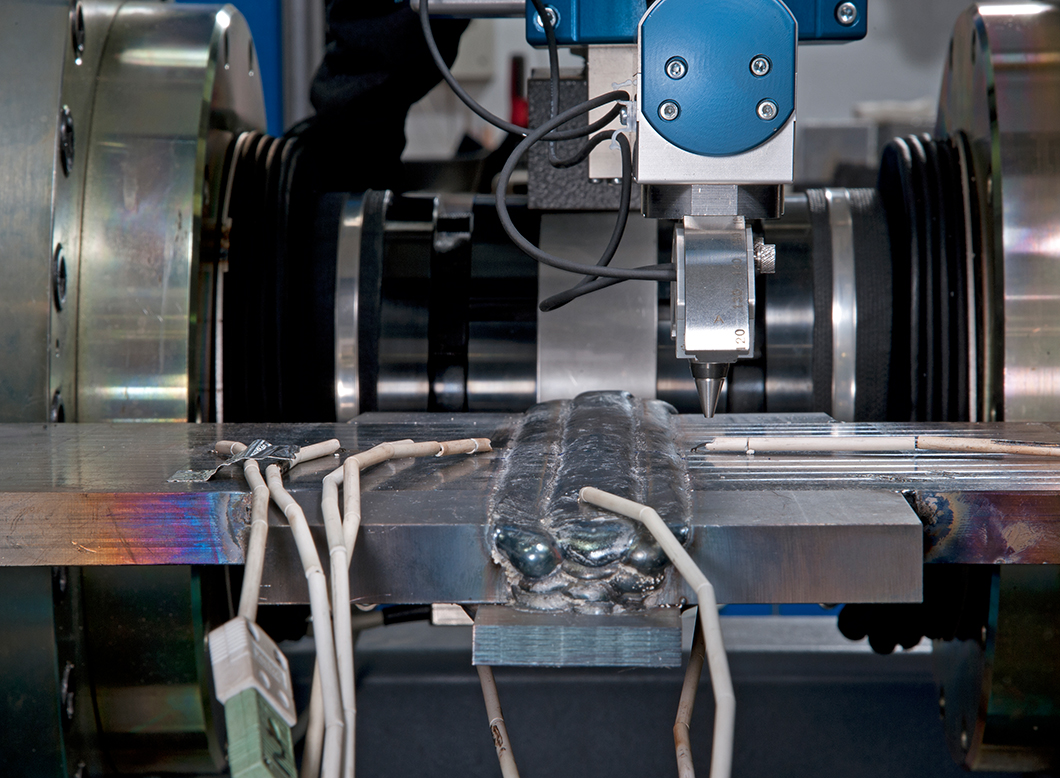

Application of X-ray diffraction to determine the residual stresses in a sub-merged arc welded joint in the 2-MN-test facility

Source: BAM

High safety requirements are specified for welded components, e.g. in power plants or petrochemical plants that are exposed to high temperatures. In particular, this includes the prevention of cracking. High-temperature, creep-resistant steels are predestined for such applications, but require extensive heat treatment after welding. The entire finished welded component, usually several 100-ton reactors or pressure vessels, must be annealed for several hours in a correspondingly large furnace. So-called stress relief cracks can occur during this process, depending on the pre-stressing from the welding process. Their cause is a complex interaction of metallurgical, welding process and mechanical influences. In order to be able to investigate this type of cracking in detail, the extreme boundary conditions occurring in practice must also be realistically reproduced in the laboratory. In addition to the heat conduction of the high-performance submerged arc welding process, the design aspects due to the enormous component dimensions, i.e. high mechanical stiffness during welding, must also be considered. A unique testing system developed at BAM enables this scaling over several orders of magnitude. At the same time, it allows online observation of the stresses and crack formation occurring during welding and subsequent heat treatment. This allows for the first time to draw conclusions about the mechanisms of crack formation as found in real components. While Part I of this series of articles focuses on the effects of the welding parameters on the mechanical stress, Part II deals with the associated metallurgical causes of the crack phenomena.

Influence of welding stresses on relief cracking during heat treatment of a creep-resistant 13CrMoV steel:

Part I - effect of heat control on welding stresses and stress relief cracking

A. Kromm, T. Lausch, D. Schroepfer, M. Rhode, T. Kannengiesser

published in Welding in the World, Vol. 64, issue 5, pages 807 - 817, 2020

Influence of welding stresses on relief cracking during heat treatment of a creep-resistant 13CrMoV steel

Part II: mechanisms of stress relief cracking during post weld heat treatment

A. Kromm, T. Lausch, D. Schroepfer, M. Rhode, T. Kannengiesser

published in Welding in the World, Vol. 64, pages 819 - 829, 2020

BAM Division Weld Mechanics and Division Testing Devices and Equipment