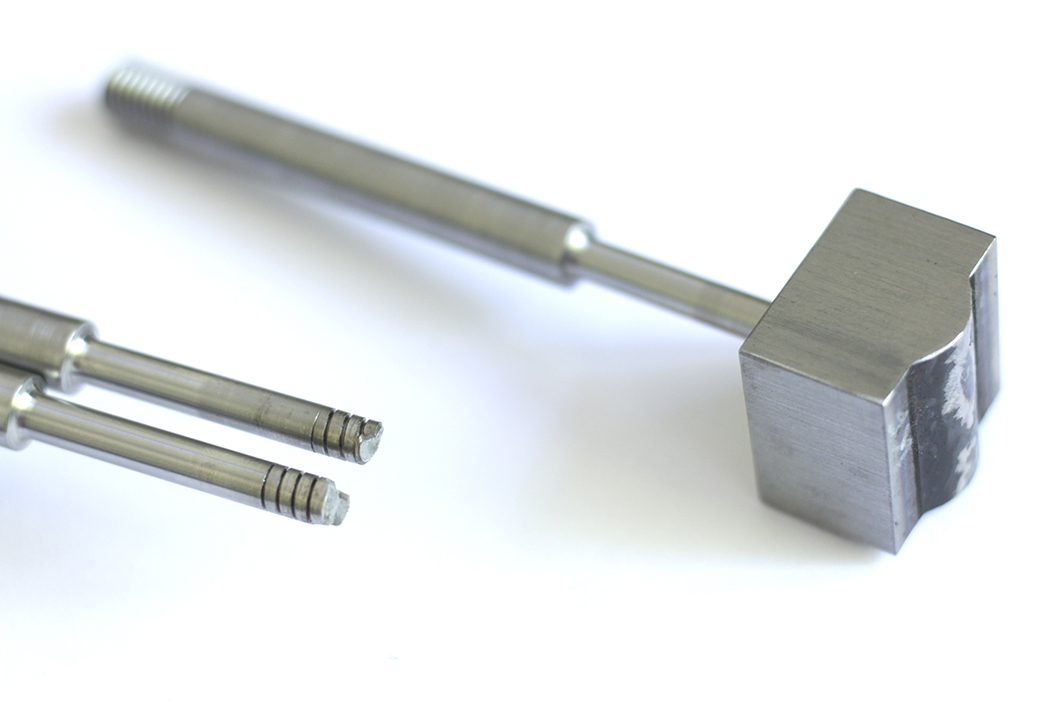

Welded and fractured implant specimens

Source: BAM, Division Weld Mechanics

In welded components made of high-strength steels, hydrogen-assisted cracking (HAC) may occur during the cooling process of the weld joint and several days afterwards. The avoidance of those microcracks requires a profound understanding of the interaction between the influencing factors of material, stresses in the weld joint and the presence of diffusible hydrogen. The microstructure in the heat-affected zone (HAZ) is of major interest, which depends on the type of base material. Steels of the 960 MPa grade can be manufactured by a quenching and tempering process (QT) or thermomechanical controlled rolling (TM) resulting in two different microstructures. However, a direct comparison of these steels and their susceptibility to HAC has not been known in the literature so far.

Therefore, in the present study the HAC behavior in the HAZ of the two high-strength steels S960QL (QT) and S960MC (TM) was investigated during gas metal arc welding using the externally loaded implant test. For this purpose, cylindrical implant specimens with a defined spiral notch were fixed in a steel plate and over-welded with a bead-on-plate weld. During cooling of the weld seam, the implant specimens were subjected to a defined tensile load. The aim of the investigations was to record the time to failure until complete fracture of the implant specimens as a function of the applied stress. In addition, metallographic analyses were used to determine the maximum tolerable stresses for crack avoidance. The implant tests were accompanied by welds to determine the diffusible hydrogen concentration in the arc weld metal. The results show that the microstructure of the HAZ has a significant influence on HAC. The HAZ of S960QL has a significantly higher hardness than the HAZ of S960MC. This is due to the increased carbon content of S960QL. In addition, the HAZ of S960MC has a finer-grained microstructure, which allows more hydrogen trapping and therefore, less hydrogen is available for HAC initiation. In the tests with the S960MC, this is reflected in a delayed fracture of the implant specimens as well as in significantly increased tolerable stresses until HAC initiation and complete fracture.

Hydrogen-assisted cracking of GMA welded 960 MPa grade high-strength steels

Thomas Schaupp, W. Ernst, H. Spindler, Thomas Kannengiesser

published in International Journal of Hydrogen Energy, Vol. 45, issue 38, pages 20080 - 20093, 2020

BAM, Division Weld Mechanics