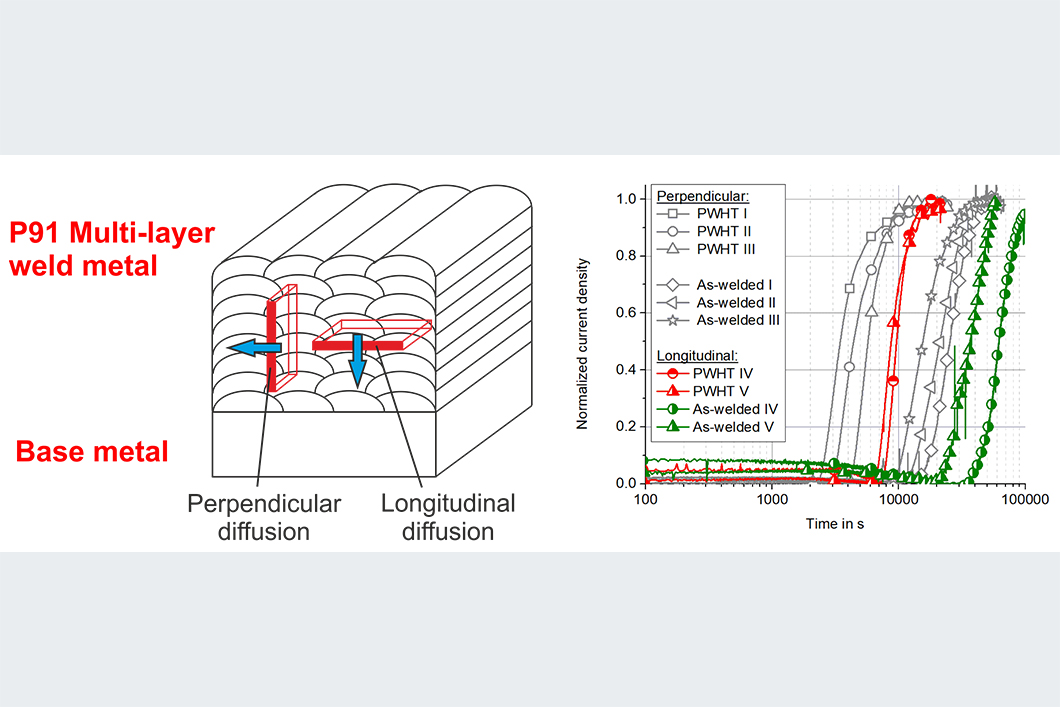

Left side: Multilayer weld metal and permeation specimen position, right side: Hydrogen diffusion as function of microstructure orientation and heat treatment condition

Source: BAM, Department Component Safety

Welded components of P91 9% Cr steel demand for careful welding fabrication with necessary post weld heat treatment (PWHT). Before the PWHT, a hydrogen removal heat treatment is necessary for avoidance of hydrogen assisted cracking (HAC). In this context, the microstructure and temperature-dependent hydrogen diffusion is important, and reliable diffusion coefficients of P91 weld metal are rare. For that reason, the diffusion behavior of P91 multi-layer weld metal was investigated for as-welded (AW) and PWHT condition by electrochemical permeation experiments at room temperature and carrier gas hot extraction (CGHE) from 100 to 400 °C. Hydrogen diffusion coefficients were calculated, and the corresponding hydrogen concentration was measured. It was ascertained that both heat treatment conditions show significant differences. At room temperature the AW condition showed significant hydrogen trapping expressed by to seven times lower diffusion coeffi-cients. A preferred diffusion direction was found in perpendicular direction expressed by high permeability. The CGHE experiments revealed lower diffusion coefficients for the AW condition up to 400 °C. In this context, a hydrogen concentration of approximately 21 ml/100 g was still trapped at 100 °C. For that reason, a certain HAC susceptibility of as-welded P91 weld metal cannot be excluded, and hydrogen removal should be done before PWHT.

Hydrogen diffusion in creep-resistant 9% Cr P91 multi-layer weld metal, erschienen im Welding in the World, 64, pages267–281 (2020)

Michael Rhode, Tim Richter, P. Mayr, A. Nitsche, Tobias Mente, Thomas Böllinghaus

BAM Department Component Safety