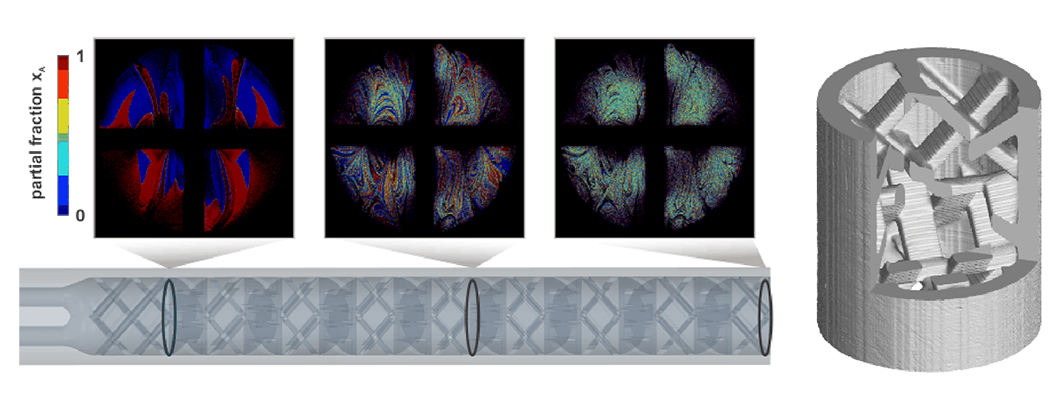

Additively manufactured SMX mixer evaluated through CFD simulation (left) and computed tomography (right)

Source: BAM

The process industry is currently evaluating the use of "modular production". In the future, standard components ("production modules") can thus be combined to form optimal production units for the production of high-quality specialty chemicals or pharmaceutical base materials. The set-up times for new products can be enormously reduced in this way, and kilograms to tons of these products can already be produced on a container scale.

In our work, a 3D-printed ceramic mixer with a diameter of only five millimeters was developed on the basis of computational fluid dynamics (CFD design). This mixer is also a sensor cell for a nuclear magnetic resonance spectrometer (NMR) and is installed in it. This allows rapid chemical reaction and mixing processes to be investigated, which are completed within a few seconds. If such a unit is used as a production module, the production of chemicals can be optimized and controlled in real time, since the NMR spectrometer is used online for quality control.

In this context the concept of the "digital twin" is also being tested. It is hoped that this will enable the design and construction of tailor-made production modules in the future, since all the knowledge required for this is stored digitally within models.

Design and validation of an additively manufactured flow cell–static mixer combination for inline NMR spectroscopy

Martin Bornemann, Simon Kern, N. Jurtz, Tobias Thiede, M. Kraume, Michael Maiwald, published in Industrial & Engineering Chemistry Research, Vol. 58, Issue 42, pages 19562-19570, 2019

BAM, Division Process Analytical Technology and Division Micro Non-Destructive Testing