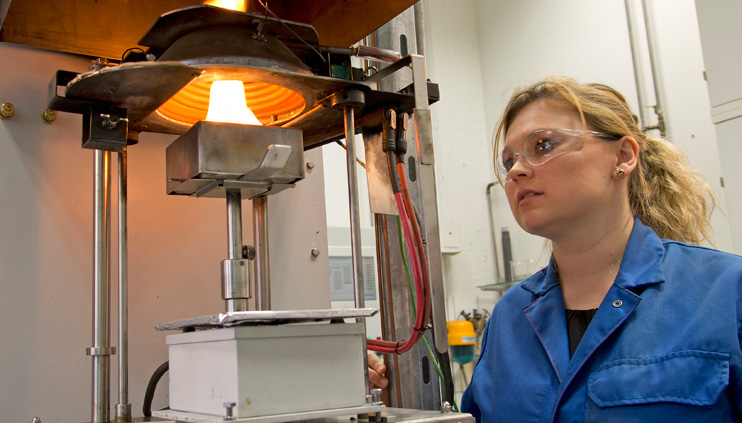

Examining flame retardant properties of a sample in the cone calorimeter

Source: BAM

BAM is researching the potential of nanotechnologies to act as innovative flame retardants in plastics. This can be well illustrated by the example of a Notebook housing: even a low percentage of certain, well-distributed nanomaterials in the housing plastic will form a closed protective layer on the surface of the housing in the event of fire. This acts as a heat shield, reduces the rate of heat release and thereby prevents the fire from spreading. In addition to nanocomposites, which are already successfully established in various flame retardant products on the market, BAM is also working on other nanotechnologies, such as nanocoatings or nanofibres.

Versatile flame retardant properties

"Nanocomposites have the appeal of being multifunctional," says Dr. Bernhard Schartel, Head of BAM's Technical Properties of Polymeric Materials Division. They can therefore make a crucial contribution to the replacement of flame retardants containing halogen. "Their multifunctionality means manufacturers can offer good value for money alongside innovation," continues Dr. Schartel.

For example, nanomaterials do not just develop a heat shield in nanocomposites, they also prevent the burning plastic from dripping. This is a key factor in passing the fire test, which – in the absence of nanomaterial – would require a further additive.

Cost-effective manufacturing process

Following various nanomaterials like sheet silicates and carbon nanotubes, BAM, together with its industry and research partners, introduced flame retardant graphene and multi-layered graphene nanocomposites. Thanks to significantly lower manufacturing costs and improved material properties, larger quantities of the nanomaterial are available for the currently highest level of demand.

The interdisciplinary team led by Dr. Schartel aims to achieve safe, practicable and environmentally friendly fire prevention. Solutions to this are just as varied as the uses of plastic. So BAM is also working on nano-heat-reflective coatings, for example for use in railway vehicles. These act like a mirror to reflect infra-red radiation and thereby effectively prevent the plastic from heating up, whereas electrospun nanofibre mats act as a protective layer to reduce the critical mass when plastics ignite.