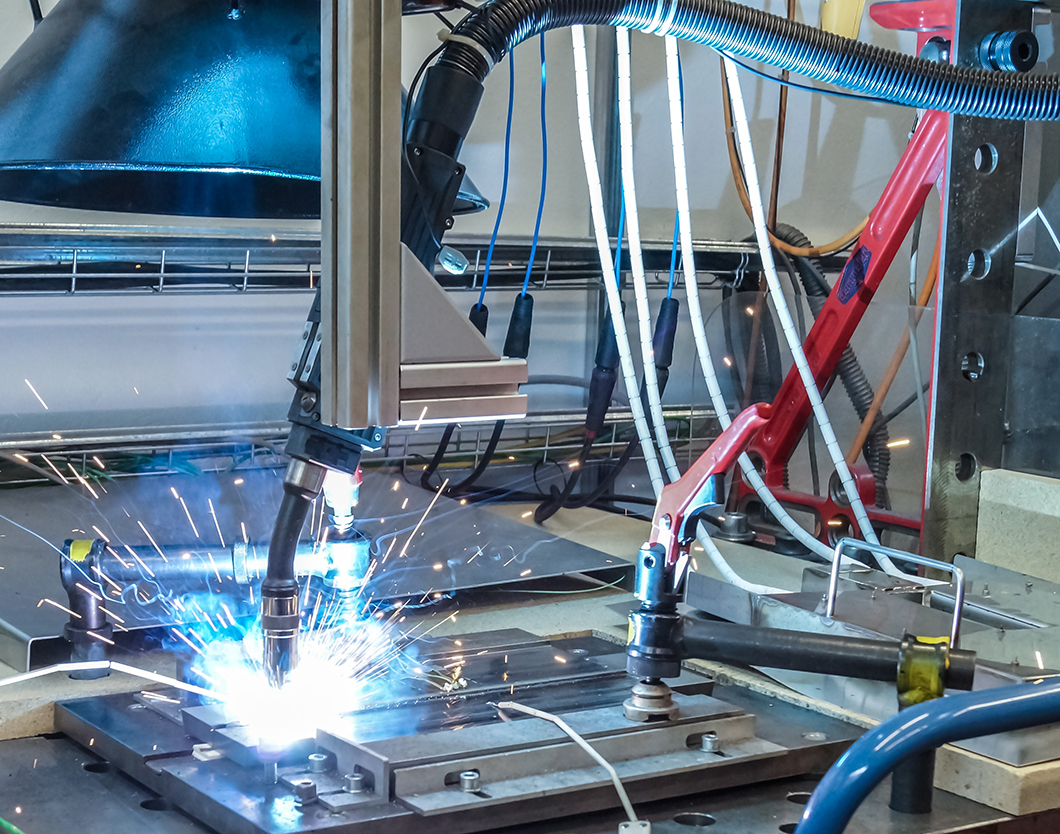

Welding of high-strength steel

Source: Nina Schröder

Project period

01/08/2020 - 21/10/2021

Project type

Project status

Ongoing

Description

The aim of the research project is to investigate the influence of alloying elements, especially microalloying elements such as Ti and Nb, on the softening of the heat-affected zone during welding of high-strength quenched and tempered fine-grained structural steels.

Location

Bundesanstalt für Materialforschung und -prüfung

Unter den Eichen 87

12205 Berlin

Challenge

To increase the strength of quenched and tempered high-strength fine-grained structural steels, the addition of microalloying elements such as Nb and Ti is essential. The standard specifications for the chemical composition of these steels specify wide alloying intervals, which makes it difficult to predict the weldability and load-bearing behaviour of the welded joints. In addition, modern welding processes with higher heat exposure are increasingly being used. This can negatively influence the phase transformation. A softening of the heat-affected zone is the result.

Objectives

The aim of the research project is to develop a physical metallurgical model that can fundamentally describe the formation of a softened zone in the heat-affected zone. For this purpose, material-scientific and welding-technological factors and methods are correlated with each other.

Methods

The focus lies on microalloying routes of quenched and tempered high-strength fine-grained structural steel S690QL. A heat-affected zone microstructure with low hardness is to be adjusted by variation of heat conduction (heat input) and heat exposure (single- and multi-layer welds). Tensile tests are carried out by means of optical deformation measurement (DIC). Further methods: Thermodynamic simulations of the microstructure and precipitation kinetics as a function of welding temperature cycles.

Funding

The project is funded by the German Research Foundation (Deutsche Forschungsgemeinschaft, DFG), project number 435083436.