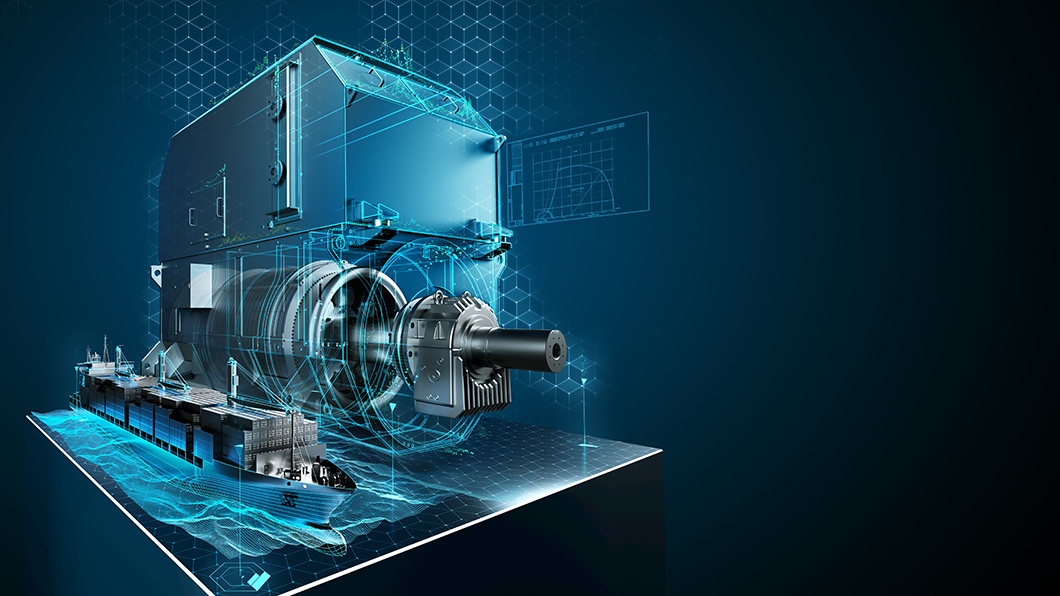

SIGENTICS M synchronous generator, modern electric drive, for example for maritime applications

Source: Siemens AG

Project period

01/01/2020 - 21/12/2022

Project type

Collaborative research project

Project status

Closed

Description

The aim of the joint project is to develop the competitive electric machine of the future. To this end, product and process innovations along the entire value-added chain are being considered.

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Unter den Eichen 87

12205 Berlin

Challenge

Electrical drives convert electrical energy into mechanical energy. Because of their environmental friendliness, high efficiency and good availability of electrical energy, they are used in a wide variety of industries and are increasingly replacing combustion engines. Demands for higher power density and shorter delivery times require new approaches to the design and manufacture of electrical machines.

Objective

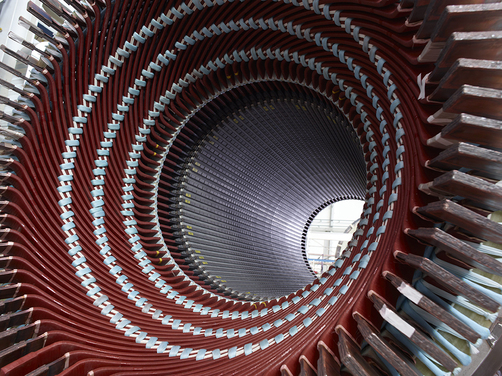

The overall objective of the project is an end-to-end development of the electric drive of the future. This includes the digital design and automated additive manufacturing of a permanent magnet rotor and components of the stator, i.e. the immovable part of the drive, based on innovative insulation technology. A digital twin forms the framework from development to operation.

Methods

To implement the Industry 4.0 concept, feedback-to-design, digital twin, autonomous manufacturing and smart maintenance will be adapted and linked. Processes for the additive production of permanent magnets and winding components, as well as the necessary joining technology will be developed and prepared for demonstration of feasibility. Oxide-ceramic and ceramic-polymer systems are being investigated as novel, additively manufacturable material systems for high-voltage insulation.

View into the stator of a classic electric drive

Source: Siemens AG

BAM's contributions

Dielectric characterisation of innovative material systems for high voltage insulation

BAM division Advanced Multi-materials Processing, Dr.-Ing. Björn Mieller

Mechanical fatigue strength of additively manufactured and joined components

BAM division Service Loading Fatigue and Structural Integrity, Dipl.-Ing. Ralf Häcker

Project coordination

Overall project: Siemens AG

Subproject BAM: Dr.-Ing. Björn Mieller

Partners

SIEMENS AG

Fraunhofer-Gesellschaft (Fraunhofer IPK, Fraunhofer FOKUS)

Technische Universität Berlin (11 departments and faculties)

10 small and medium enterprises in Berlin and Brandenburg

Funding

The project is carried out within the Werner-von-Siemens Centre for Industry and Science. It is funded by the Investitionsbank Berlin (ProFIT) and co-financed by the European Regional Development Fund (ERDF).

Logo of the Werner-von-Siemens Centre for Industry and Science

Source: WvSC

Logo of the EU European Regional Development Fund

Source: EU