Wind turbines with jacket support structures in an offshore wind farm

Source: Volker Schlichting/EyeEm/Getty Images

Project period

01/02/2021 - 31/01/2024

Project type

Collaborative research project

Project status

Closed

Description

DiMoWind–Inspect deals with the development of a digital asset management system for offshore wind turbine structures with the aim of enabling targeted predictive inspections on the base of digital processed condition information.

Location

Bundesanstalt für Materialforschung und -prüfung (BAM)

Unter den Eichen 87

12205 Berlin

Experiment for automated crack detection Source: BAM, division Buildings and Structures

Source: BAM

Source: BAM

Source: BAM

Partners

Bundesanstalt für Materialforschung und -prüfung (BAM)

Hochschule für Technik und Wirtschaft Dresden

Jörss-Blunck-Ordemann GmbH

MR Chemie GmbH

WindMW Service GmbH

Funding

Bundesministerium für Wirtschaft und Klimaschutz (BMWK) unter the project management organization Forschungszentrum Jülich GmbH.

DiMoWind-Inspect – Digital modeling processes in the recurring inspection of wind turbines

Offshore wind farms in the North and Baltic Seas are a central component of Germany's future energy system. To ensure the competitiveness of this type of energy generation, wind turbines must be managed intelligently so that their availability and thus their wind power benefits are maximized while the costs for their maintenance are minimized.

In particular, the support structures (tower and foundation) of wind turbines are still inspected and evaluated at short, rigid intervals. Such periodical inspections currently form the basis for deriving maintenance measures. Data from periodical inspections are presently not systematically recorded and evaluated. A unified, standardized, and digitized handling of inspection data, their classification, referencing, and systematic evaluation is one of the major tasks for the future. The joint project DiMoWind - Inspect aims at creating the foundation for a digital systematization of damage-related findings from periodic inspections on the different levels of detection and evaluation. On this basis, the remaining useful life of aging support structures in offshore wind farms and optimal inspection and maintenance strategies for these systems will be determined.

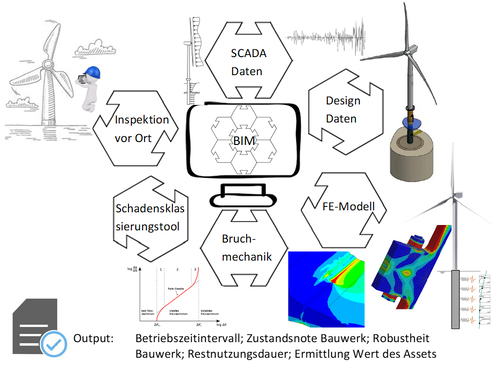

Interaction of the different elements within the framework of a digitalised maintenance strategy

Source: JBO Jörss-Blunck-Ordemann GmbH

Modeling processes and inspection planning

The main technical focal points and development goals of the BAM subproject are:

- Development of the data management concept for the load-bearing structures to be monitored during operation and the expected findings, including a reproducible digital positioning of the findings on the structure

- Development of a reference designation system and a classification system for structural findings and damage

- Automation of the comparison of damage across different structures

- Development of procedures for the integrability of the results in the Common Data Environment

- Extended understanding of fracture and crack propagation behavior of offshore-typical steel structure details due to material fatigue caused by corrosion damage

- Development of an applicable concept for risk- and cost-optimized planning of inspections and maintenance measures based on the data modeling developed in the project in consideration of the latest damage models and novel inspection and monitoring methods

- Further development and testing of crack luminescence for fatigue crack detection for offshore applications

- Further development of crack luminescence by means of automated image evaluation as base for integration in digital asset management and proto-typical application

- Provision of results and routines for the development of a software- and BIM-based methodology for the asset management of wind turbine structures.

Project coordination

Bundesanstalt für Materialforschung und -prüfung (BAM)

BAM sub-project

Partners

JBO Jörss-Blunck-Ordemann GmbH

MR Chemie GmbH

Wind MW Service GmbH

HTW Dresden Hochschule für Technik und Wirtschaft

Funding

The project "DiMoWind-Inspect – Digital modeling processes in the recurring inspection of wind turbines" (funding code 03EE3039A) is funded by the Bundesministerium für Wirtschaft und Klimaschutz (BMWK) unter the project management organization Forschungszentrum Jülich GmbH.

Source: BMWi and Forschungszentrum Jülich