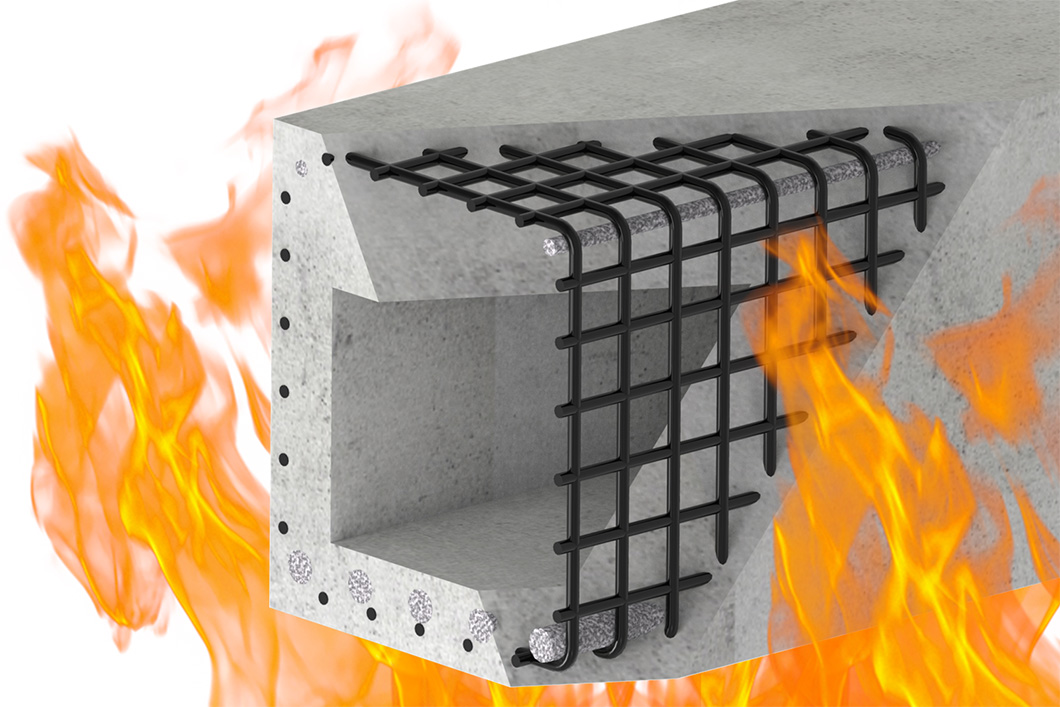

3D model of a load-bearing element made of textile-reinforced concrete, developed within the project and tested for its fire resistance.

Source: BAM

The Federal Institute for Materials Research and Testing (BAM) and the University Centre for Energy Efficient Buildings of CTU (UCEEB) in Prague have launched a joint research project to investigate behaviour of textile-reinforced concrete under fire exposure. The aim is to expand the application possibilities of this innovative building material while contributing to safe and sustainable construction.

Textile-reinforced concrete is a modern composite material consisting of a fine-grained concrete matrix and a textile reinforcement – typically made of carbon, glass, or basalt fibers. Unlike conventional reinforced concrete, which uses steel bars for reinforcement, textile-reinforced concrete incorporates flexible, corrosion-resistant fabrics embedded in multiple layers within the concrete.

The result is extremely thin, lightweight, and yet durable structural elements that are ideal for delicate constructions, renovations, and resource-efficient building. The textile reinforcement provides high tensile strength despite the reduced material thickness. When a structural element is subjected to loads – such as the weight of people or wind forces – the concrete absorbs the compressive forces while the embedded carbon fibers take up the tensile forces, ensuring the component remains stable and load bearing.

So far, textile-reinforced concrete has primarily been used under normal temperature conditions. However, for load-bearing structural components in buildings, fire protection requirements often apply. Reliable scientific data is still lacking in this area. This is precisely where the new research project comes in: The scientists aim to understand how textile-reinforced concrete behaves under high temperatures and how it can be designed to maintain its stability even under extreme conditions.

The project focuses on investigating of material properties at elevated temperatures and developing and testing lightweight structural elements made of textile-reinforced concrete. In addition, computational modelling of behaviour under fire exposure, and assessing the environmental impact of structural elements throughout their entire life cycle are also taken into account.

“The challenge lies in making the excellent mechanical properties of textile-reinforced concrete reliably usable even under extreme temperature conditions,” explains Richard Fürst, project lead at BAM. “With our research approach, we aim to precisely understand how the materials behaves in case of fire and derive specific solutions for its safe application in load-bearing components.”

BAM contributes its long-standing expertise in fire safety and the high-temperature behaviour of construction materials while CTU UCEEB specializes in the development and assessment of textile-reinforced concrete. Together, both institutions aim to generate new scientific insights that will enable the safe and sustainable use of textile-reinforced concrete in the construction industry.

The bilateral research project FiReC3 is jointly funded by the German Research Foundation (DFG) and the Czech Science Foundation (GAČR).