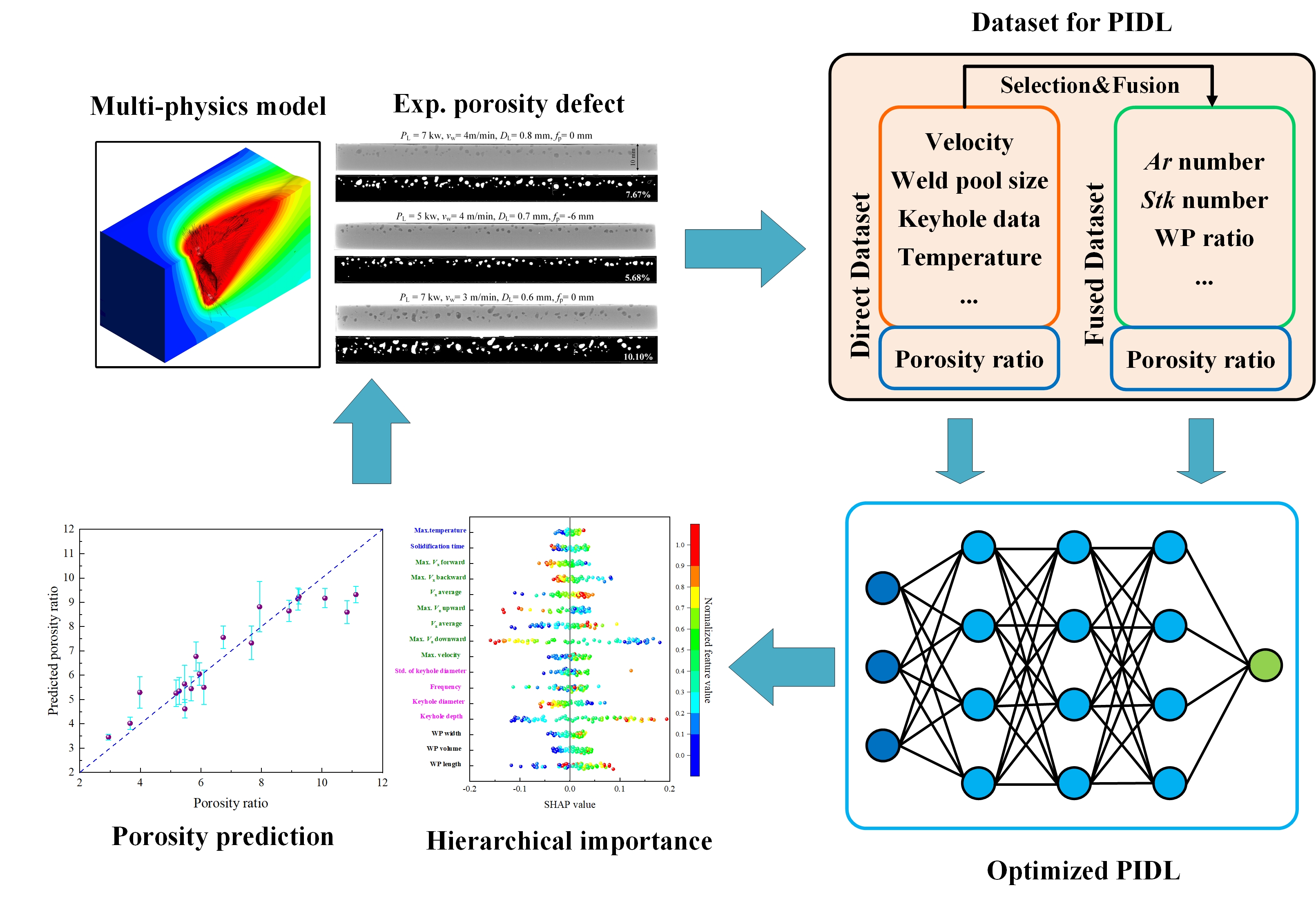

The architecture of the physics-informed deep learning (PIDL) framework. The PIDL model can provide an accurate prediction of the porosity level and the hierarchical importance of different physical factors.

Source: BAM

The laser welding process is an important manufacturing technology for industry-relevant metallic materials including steel, Al alloy, Ti alloy, etc. Various typical or potential applications can be found in shipbuilding, automobile, aerospace, and large high-pressure and vacuum vessels. However, its application is often hindered by the occurrence of porosity defects. This defect will deteriorate the continuity of the weld structure, and correspondingly the homogeneity of weld properties. Stress concentrations will be produced at the gas/solid interface under static or dynamic loads, leading to structural failure.

By far, an accurate prediction of the porosity defects and an insight into its formation mechanism are still challenging due to the high temperature of the welding area (more than 3000 K), the opaque nature of the molten metal, and the highly nonlinear physics involved. The classic strategy using the welding parameters as the inputs of the machine learning model can still not provide satisfying prediction accuracy. In this paper, we propose a physics-informed deep learning (PIDL) framework by utilizing multi-physics modeling and experimental data to predict the porosity level during laser beam welding of aluminum alloys. The well experimentally validated multi-physics model can identify the most important physical variables concerning the critical formation procedures of the porosity defects. Using the physical variables as inputs, the PIDL model shows great superiority in predicting the porosity ratio, with a reduction of mean square error by 41 %, in comparison with the conventional DL model trained with welding parameters. Furthermore, the selected variables are fused into dimensionless features with explicit physical meanings to improve the interpretability and extendibility of the PIDL model.

Based on a well-trained PIDL model, the hierarchical importance of the physical variables/procedures on the porosity formation was revealed for the first time. The keyhole ratio is identified as the most influential factor in porosity formation, and it can be used as a direct index to describe the tendency of defect occurrence. The downward flow-driven drag force also shows a significant influence. However, its importance is still underestimated and should receive more attention. The findings in this paper offer a valuable guideline for process optimization and porosity minimization, not only for welding but also for other laser-based material processing including additive manufacturing.

Toward prediction and insight of porosity formation in laser welding: A physics-informed deep learning framework

Xiangmeng Meng, Marcel Bachmann, Fan Yang, Michael Rethmeier

Acta Materialia, Volume 286, March 2025