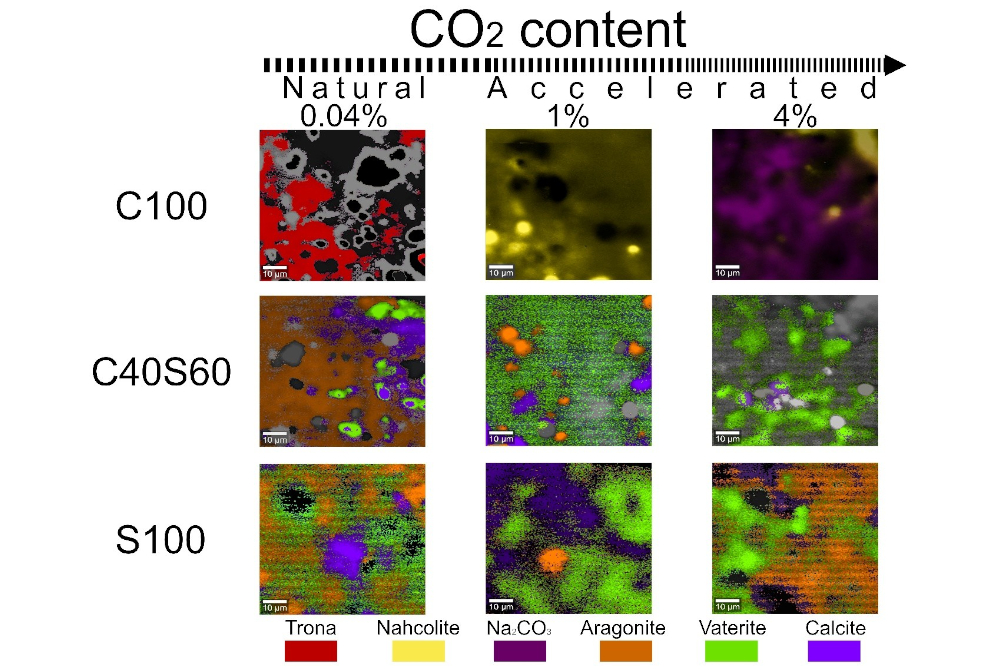

Raman phase maps of AAMs after carbonation at 0.04%, 1% and 4% CO2. Trona and nahcolite are sodium carbonates; calcite, vaterite and aragonite are calcium carbonate polymorphs.

Source: BAM

The urgent need to reduce anthropogenic CO2 emissions as rapidly and as permanently as possible has prompted developments also in the construction industry. Although significant progress has been made in developing low-emission cements and concretes, new solutions are still required. In this context, alkali-activated materials (AAM) and AAM-based concretes emerge as promising alternatives. To be used in reinforced concrete elements, it is crucial that the carbonation resistance of AAMs is comparable to that of conventional cements. However, our understanding of the degradation mechanisms of these materials is still limited. Carbonation of AAMs is complex, as it can be influenced by various factors, such as chemical composition and permeability. In this context, a DFG-funded research project was carried out at BAM’s division 7.4 to elucidate the rate of carbonation and its effects in high-, intermediate-, and low-Ca AAMs. The main objectives were to identify the parameters which determine the carbonation rate under natural CO2 concentration, and to analyse carbonation at higher-than-natural CO2 concentrations used for accelerated testing.

The concretes were produced using systematically varied amounts of ground granulated blast furnace slag and calcined clay. Carbonation resistance tests were conducted under natural (0.04 %) and accelerated (1 % and 4 %) CO2 concentrations. Hardened samples were also analysed as regards their chemical and mineralogical composition as well as their microstructure. The results show that the carbonation resistance of AAMs depends mainly on the ratio between the water in the mix and the amount of carbonatable components (calcium, magnesium, sodium and potassium oxides) in the binder. The remaining variations in carbonation resistance could be assigned to differences between the pore structures of the hardened binders with similar ratios. Well-designed AAM concrete with a low ratio of water and reactive materials exhibited a carbonation resistance very similar to that of conventional Portland cement concrete. Accelerated carbonation resistance tests did not accurately reflect the natural carbonation behaviour in AAM concretes with low calcium content in the binder, which necessitates the development of new accelerated methods.

Carbonation resistance of alkali-activated GGBFS/calcined clay concrete under natural and accelerated conditions

Luís Urbano Durlo Tambara Jr., Astrid Hirsch, Frank Dehn, Gregor Gluth

Construction and Building Materials, October 2024