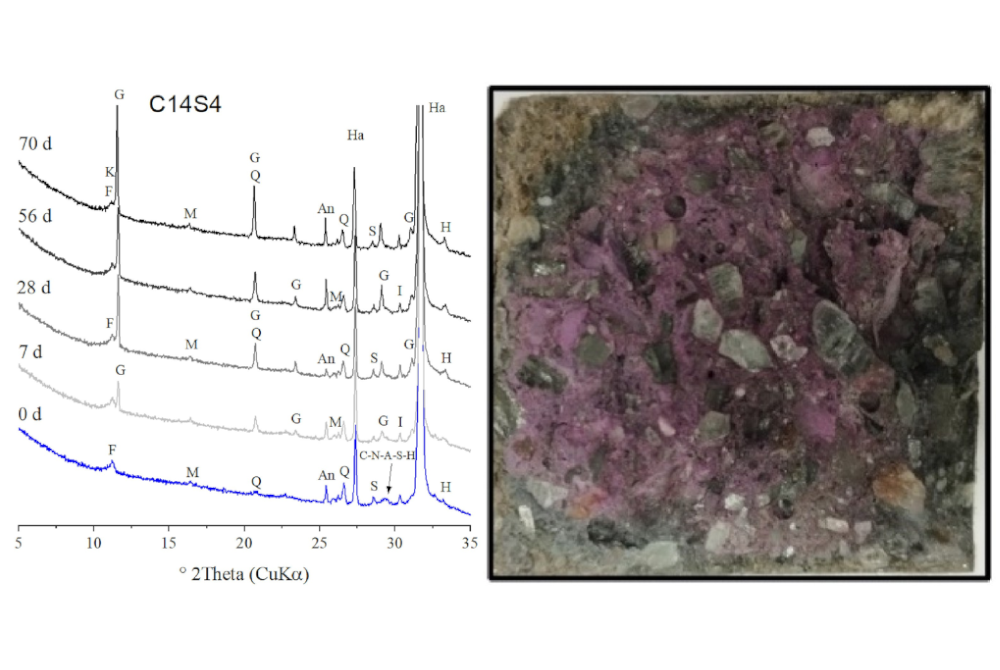

Right panel: X-ray diffractograms of a hybrid cement-based salt concrete after different exposure times; Left panel: Fracture surface of a hybrid cement-based salt concrete sprayed with indicator solution after an exposure time of 28 days.

Source: BAM

Several of the underground repositories that are currently used as interim storage facility or considered for final disposal of nuclear waste were previously salt mines, e.g., the Asse mine and the Morsleben repository in Germany, and thus the host rock in these repositories is an evaporite rock. The planned measures to avoid radionuclide escape from such repositories into the biosphere include the construction of sealing structures made from concrete with salt aggregate (so-called ‘salt concrete’) to close drifts in the mine. The cements that have been evaluated as regards their suitability to produce the salt concrete include magnesium oxychloride cement, low-pH cements and, more recently, hybrid alkaline cements (HAC). In a recent research project, BAM’s division 7.4 has developed and characterized salt concretes based on HAC with the aim to better understand the factors that determine their chemical stability and permeability under the expected conditions, i.e., when attacked by magnesium chloride-rich brine.

Concretes produced from salt aggregate and HAC, an alkali-activated slag/fly ash blend, and a Portland cement were exposed to a magnesium chloride-rich saline solution, representing a solution formed after contact of surface water with evaporite rock (rock salt). The hydration and deterioration of the concretes were studied with X-ray diffraction, thermogravimetric analysis, pH mapping and permeability measurements. The results show that calcium silicate hydrate (C-S-H) or sodium-substituted calcium aluminium silicate hydrate (C-N-A-S-H) and Friedel's salt were the major reaction products in the concretes prior to exposure to the saline solution. During exposure to the saline solution, C-S-H/C-N-A-S-H dissolved, and gypsum and a secondary AFm phase formed. The durability of the concretes improved with increasing amounts of Portland clinker in the cements, due to the associated differences in permeability and chemical resistance. Nevertheless, a massive increase of permeability occurred for all concretes, likely caused by crack formation due to the formation of gypsum from anhydrite in the salt aggregate. Thus, the behaviour of the concretes differed from, and was more complex than, the behaviour of plain cement pastes.

Influence of salt aggregate on the degradation of hybrid alkaline cement (HAC) concretes in magnesium chloride-rich saline solution simulating evaporite rock

Ricky Henning, Patrick Sturm, Sylvia Keßler, Gregor J.G. Gluth

Applied Geochemistry 168, 2024