Off shore wind turbines (Digital Composite)

Source: Michael Betts/DigitalVision/Getty Images

Online condition monitoring of submarine power cables helps to detect failures and damages of the cables and to react on time in order to prevent total destruction. As offshore wind energy becomes more and more important for today's renewable energy demand, there is also an increased need for effective condition monitoring of offshore installations and, in particular, of submarine power cables with lengths exceeding 100 km. This long-range sensing in a hazardous environment poses many challenges for the development of appropriate sensors.

Distributed fibre optic sensors (DFOS) fulfill the need for a continuous online monitoring and make possible to localize disturbances along the complete power cable since the fiber itself is the sensor. DFOS are particularly suited for power cable monitoring as they can be easily embedded (due to their small size) in the cables during the manufacturing process. What is more, optical fibres and sensors can measure in high voltage environments.

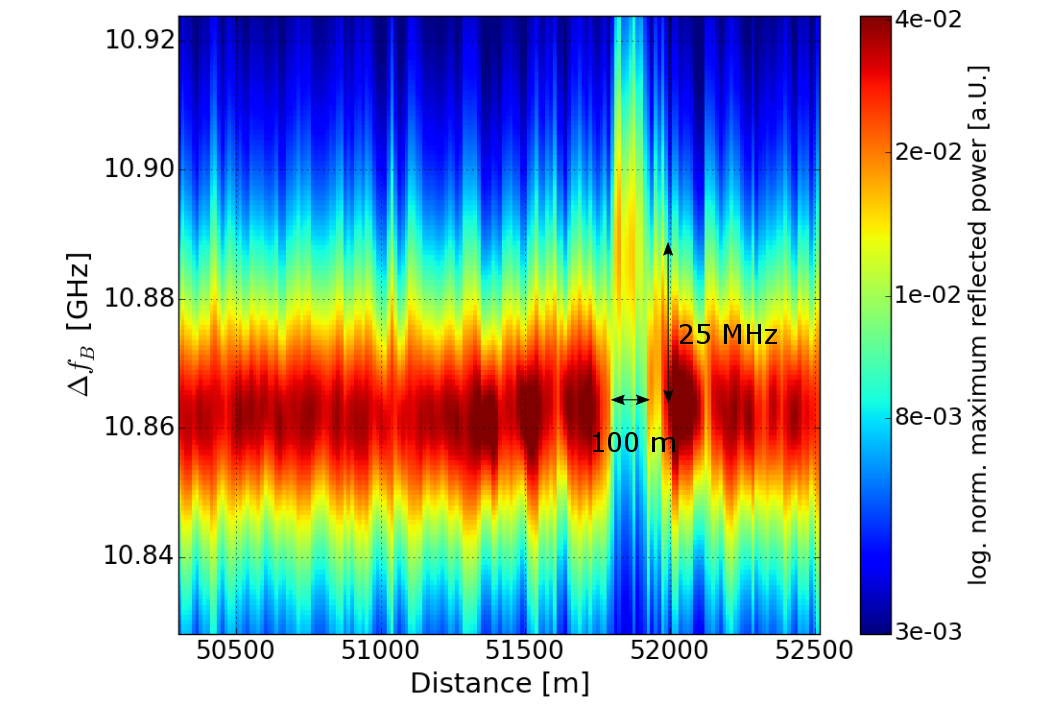

Detection of a temperature event at 51.7 km of an optical fiber

Source: BAM, Division Fibre Optic Sensors

Brillouin scattering is sensitive to changes of temperature, strain and humidity in optical fibres and is used in a wide range of applications like condition monitoring of pipelines, dikes, river embankments and high voltage cables. In this paper we demonstrate 63 km Brillouin Optical Frequency-Domain Analysis (BOFDA) for temperature and strain monitoring of submarine power cables.

63 km BOFDA for temperature and strain monitoring

Thomas Kapa, Andy Schreier, Katerina Krebber

Sensors 2018, 18, 1600

BAM Department Non-destructive testing, Division Fibre Optic Sensors