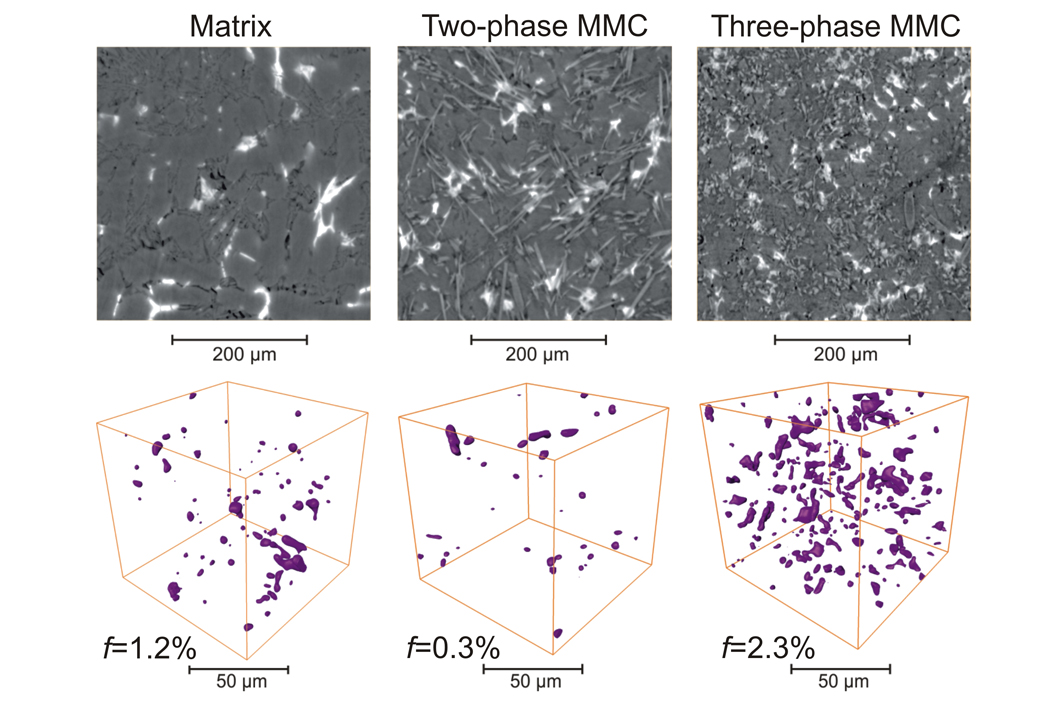

2D reconstructed slices and 3D rendering, with indication of the damage volume fraction (f), after failure under compression for the three types of studied materials.

Source: BAM, Division Micro Non-Destructive Testing

Usually Al-Si alloys are used for the production of automotive pistons. Piston alloys undergo overaging of the Al-matrix during service owing to accumulated long-term exposure at temperatures around 250°C. Strength retention, particularly at high temperatures, is achieved by a transfer of load from the weakened matrix to the stable and rigid networks of Si and aluminides. Si phase, inside the alloy, builds 3D interconnected structure, which can be vied as reinforcement. The creation of Metal Matrix Composite (MMC) by addition of the ceramic reinforcement to the alloy will improve strength and creep resistance. MMC consisting of an as-cast AlSi12CuMgNi alloy reinforced with 15 vol% Al2O3 short fibres (two-phase) and with 7 vol% Al2O3 short fibres and 15 vol% SiC particles (three-phase), were studied.

Synchrotron computed tomography (CT) at the BAMline (BESSY II, HZB) was employed to disclose distribution, orientation, and volume fraction of the different phases. Also, internal damage after compression test was directly observed in CT reconstructions. Significant debonding between Al matrix and SiC particles was found. Those observations allowed rationalizing the load partition between the constituent phases of two different composites, experimentally determined using in-situ neutron diffraction. A Maxwell homogenization scheme successfully was used for the simulation of the stress differences determined by neutron diffraction experiment and also for the calculation of absolute stress values, which cannot be obtained experimentally.

Stress-induced damage evolution in cast AlSi12CuMgNi alloy with one- and two ceramic reinforcements

Sandra Cabeza, Tatiana Mishurova, G. Garces, G. Requena, Giovanni Bruno, I. Sevostianov

Journal of Material Science, September 2017, Volume 52, Issue 17, pp 10198–10216

BAM Department Non-destructive Testing, Division Micro Non-Destructive Testing