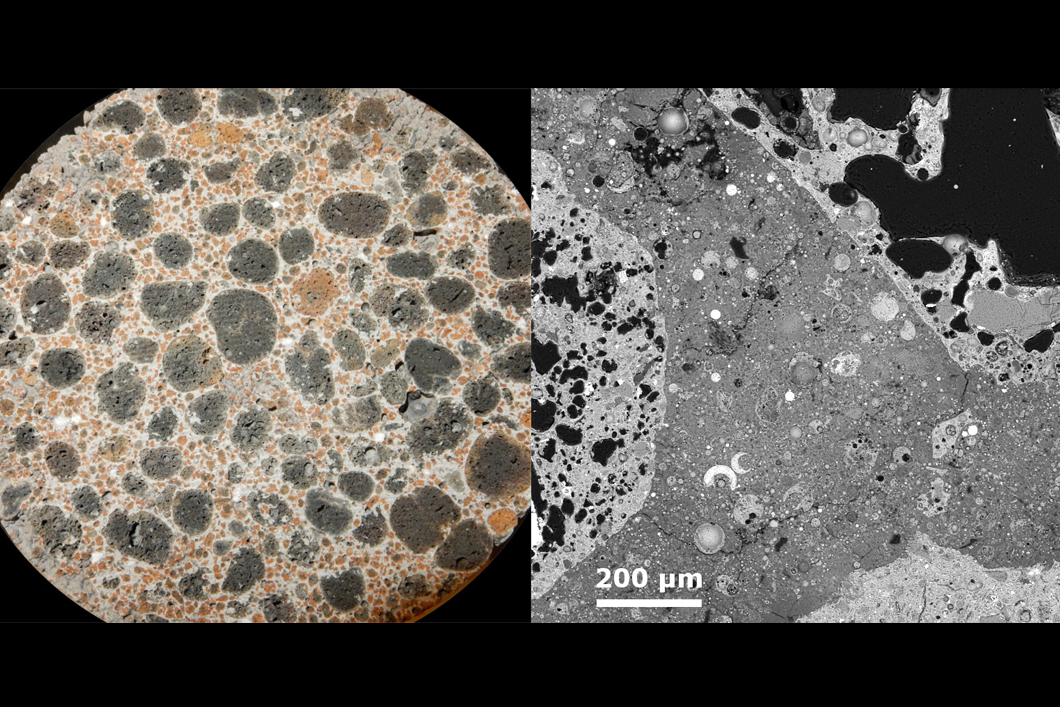

Left: macroscopic picture of the geopolymer lightweight concrete (ground surface, width of figure approx. 8.7 cm); right: SEM picture of the geopolymer lightweight concrete

Source: BAM, Division Technology of Construction Materials

The development of novel binders for concrete and mortar currently sees a renaissance, inter alia due to the fact that the production of conventional cement is responsible for a significant fraction of worldwide anthropogenic greenhouse gas emissions. One of these alternative binders are so-called geopolymers. For these binders, generally hard coal fly ash is used as the solid precursor; through addition of an alkaline activator solution, e.g. sodium silicate solution, a three-dimensional inorganic polymer network is formed. This reaction imparts the strength to the hardened binder and, thus, to the concrete or mortar. Geopolymers of appropriate composition can possess a significantly better resistance against salts, acids and high temperatures than conventional cements.

In a collaborative project of the divisions 7.4 Technology of Construction Materials and 7.3 Fire Engineering with the Curtin University, Perth, the thermomechanical properties of fly ash-based geopolymer concretes with quartz aggregate and with lightweight aggregate (expanded clay) were studied. The study revealed a complex behavior that differs in important aspects from the behavior of conventional concretes. For example, the strength and the stiffness of the concretes decrease only slightly above approx. 300 °C, i.e. in the temperature range that is critical in the case of fire. A particularly beneficial behavior is exhibited by the geopolymer concrete with lightweight aggregate: up to 600 °C only minor thermal deformations occur, and after going through a moderate minimum at 300 °C its strength increases with further increasing temperature. This greatly improved behavior compared to conventional lightweight concretes is, at least partly, caused by sintering processes in the geopolymer matrix on heating.

In addition to these results, the paper (W.D.A. Rickard, G.J.G. Gluth, K. Pistol, Cement and Concrete Research 80 (2016) 33–43) presents for the first time simplified relationships as stress–mechanical strain curves for this class of concretes that allow the structural engineer to design and dimension structural members made from these concretes for the case of fire exposure (structural fire design). The paper also documents the successful cooperation with the Curtin University that is currently continued in related projects.